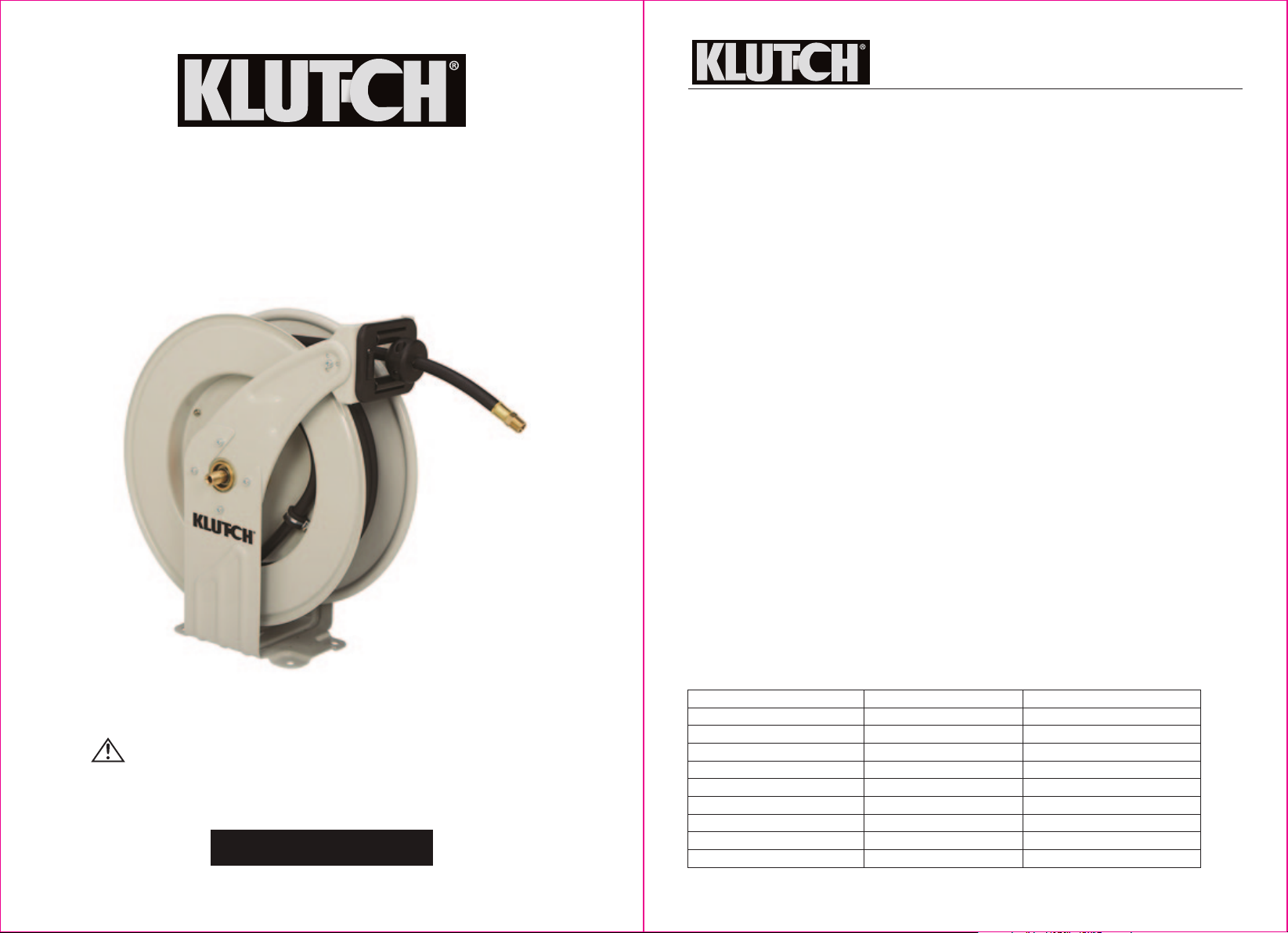

50ft. Industrial Air Hose Reels

OWNER’S MANUAL

50ft. Industrial Air Hose Reels

OWNER’S MANUAL

Important Safety Considerations

WARNING:

• Read and understand all instructions. Failure to follow all instructions may result in serious

injury.

• The warnings, cautions, and instructions in this manual cannot cover all possible conditions

or situations that could occur. Exercise common sense and caution when using the reel.

Always be aware of the environment and ensure that the reel is used in a safe and

responsible manner.

• DO NOT allow persons to operate or assemble the reel until they have read this manual and

have developed a thorough understanding of how it works.

• DO NOT modify the reel in any way. Unauthorized modification may impair the function

and/or safety and could affect the life of the reel.

• Use the right tool for the job. DO NOT attempt to force a small equipment to do the work of

larger industrial equipment. There are certain applications for which this equipment was

designed. It will do the job better and more safely at the capacity for which it was intended.

DO NOT use this equipment for a purpose for which it was not intended.

• Industrial or commercial applications must follow OSHA requirements.

WARNING:

WORK AREA SAFETY

• Inspect the work area before each use. Keep the work area clean, dry, free of clutter, and well

lit. Cluttered, wet, or dark work areas can result in injury. Using the reel in a confined work

area may put you dangerously close to other cutting tools and rotating parts.

• Do not use the reel when there is a risk of causing a fire or an explosion; e.g., in the presence

of flammable liquids, gases, or dust. The reel can create sparks, which may ignite the dust or

fumes.

• Keep children and bystanders away from the work area while operating the reel. Do not allow

children to operate the reel.

• Be aware of all power lines, electrical circuits, water pipes, and other mechanical hazards in

your work area. Some of these hazards may be below the work surface hidden from your

view and may cause personal harm or property damage if unintentionally contacted.

PERSONAL SAFETY

• Stay alert, watch what you are doing, and use common sense when operating the reel. Do not

use the reel while you are tired or under the influence of drugs, alcohol, or medication. A

moment of inattention may result in serious personal injury.

• Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

• Use ANSI compliant safety goggles or safety glasses with side shields, or when needed, a

face shield. Use a dust mask in dusty work conditions. Also use non-skid safety shoes,

hardhat, gloves, dust collection systems, and hearing protection when appropriate.

• Do not overreach. Keep proper footing and balance at all times.

• Secure the work with clamps or a vise instead of your hand when practical. This safety

precaution allows for proper tool operation using both hands.

CAUTION:

REEL USE AND CARE

• Check for damaged parts before each use. Carefully check that the reel will operate properly

and perform its intended function. Replace damaged or worn parts immediately. Never

operate the reel with a damaged part.

• Disconnect the air or fluid supply from the reel before making any adjustments, changing

accessories, or storing the tool. Such preventive safety measures reduce the risk of starting

the tool accidentally.

• Use only accessories that are recommended by the manufacturer for use with the reel.

Accessories that may be suitable for one reel may create a risk of injury when used with

another reel. Never use an accessory that has a higher operating pressure than the reel itself.

• Inspect the reel, hose, and accessories for damage or excessive wear before each use. If you

find damage do not use the reel.

Specific Operation Warnings

WARNING:

• Wear ANSI Z87.1 compliant safety goggles or safety glasses with side shields when

assembling and using the hose reel.

• Assemble the hose reel on a clean workbench.

• Keep children away from the work area. If not in use, store out of the reach of children.

• Ensure that reel is properly installed before connecting input and output hoses.

• Make sure incoming pressure does not exceed the rated pressure (300 PSI) for reel.

• Before connecting a pressure source, ensure that supply pressure does not exceed

maximum working pressure rating of reel.

• Never attach any tool or accessory to the hose unless it is capable of safely operating at a

pressure greater than the supply pressure.

• If a leak occurs in the hose or reel, remove system pressure immediately.

• If reel ceases to unwind or rewind, remove system pressure immediately.

• Do not kink the hose. Do not step on the hose or drive or drag objects over the hose. Do not

place any objects on the hose or hose reel.

• Pull the hose from the reel by grasping the hose itself, not the valve.

• Bleed fluid/gas pressure from reel before servicing it.

• Use soap and water when checking for air leaks. Exposure of skin directly to pressurized air

or fluids could result in severe bodily injury.

• Remember, even low pressure is very dangerous and can cause personal injury or death.

WARNING:

This product may contain chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm.

Assembly

WARNING:

To avoid a dangerous sudden release of pressure that can cause severe injury, ensure that the

pressure source for the reel is turned off and the supply hose is not pressurized.

Note: Before beginning assembly/installation, purchase appropriate hardware for mounting the

reel. The mounting base has four 1/2” (12.7mm) holes for mounting on a suitable flat surface.

1. Prior to mounting the hose reel, ensure that the supply hose pressure does not exceed the

maximum working pressure of the hose reel. Also check that the pressure source is turned

off and the supply hose for the reel is not pressurized.

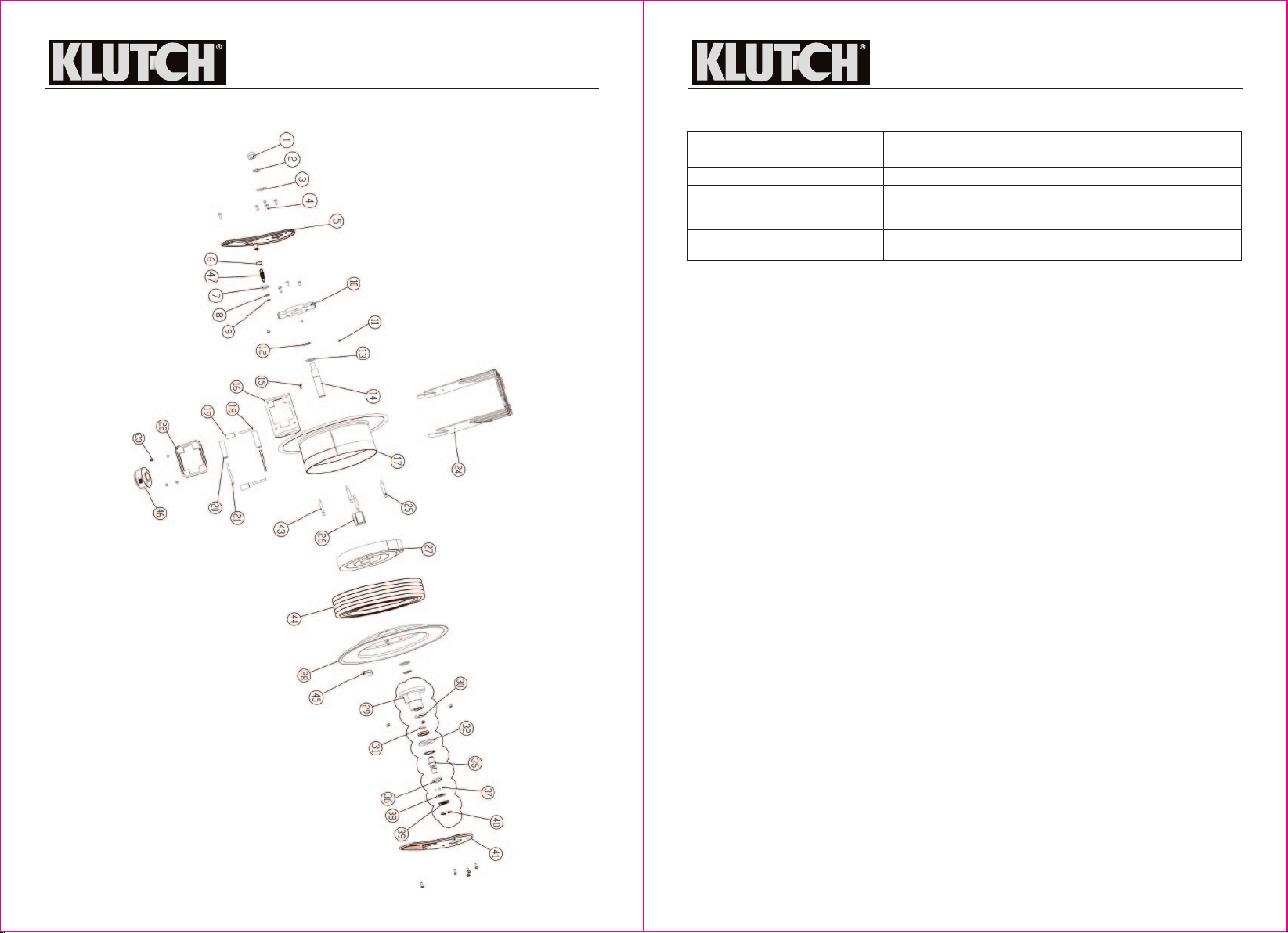

2. Unpack the reel then check that all parts are present and inspect for damage. Check reel

function for smooth rotation.

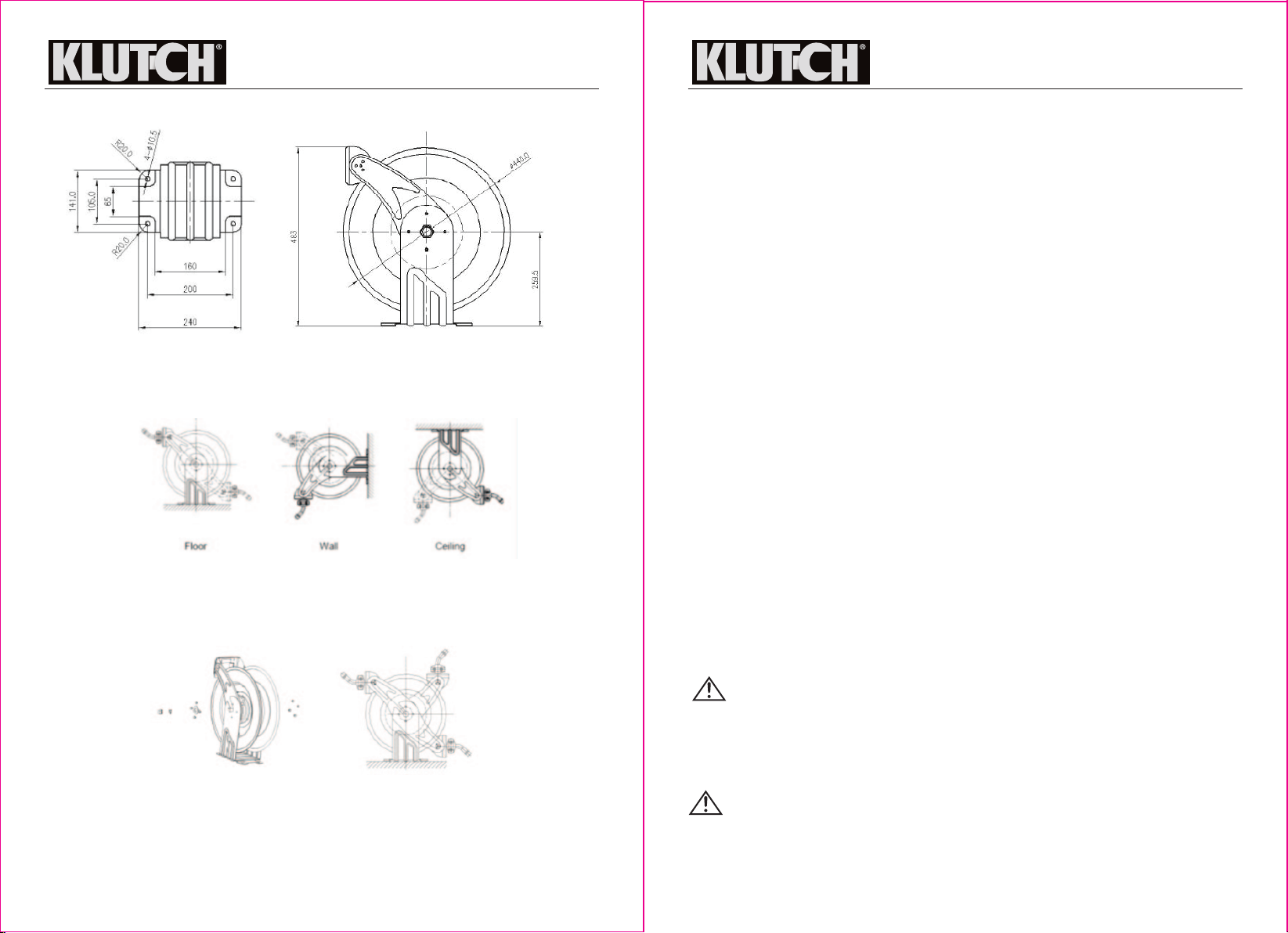

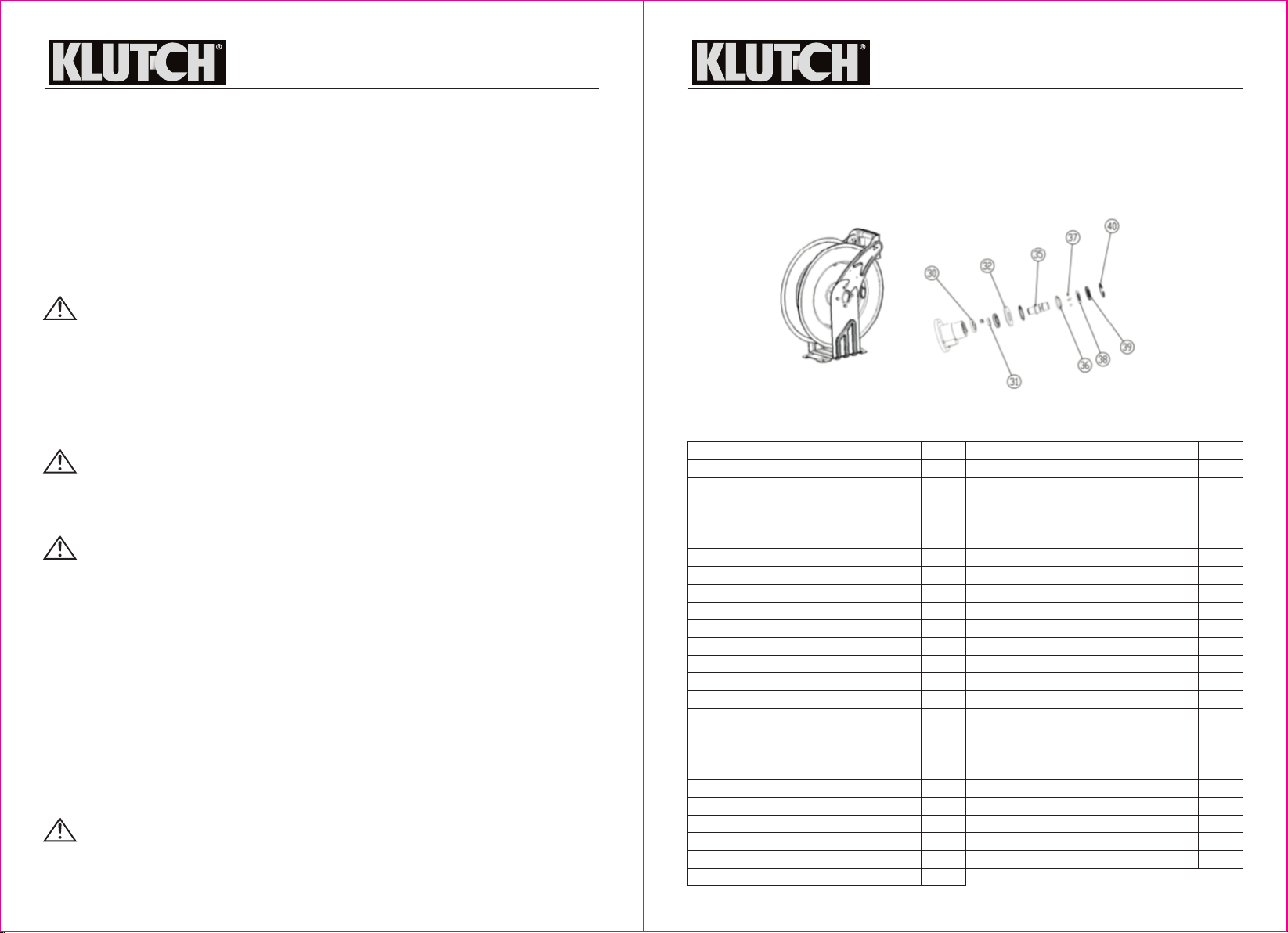

3. Fasten the mounting base (24) in the desired location. Reel dimensions and the pattern of

the mounting holes in the base are shown below. Tighten all hardware securely.

2 of 9 3 of 9