figure 4). It has to be located left to the instrument and easily reachable by the operator. The circuit breaking

device must be identified as the equipment power disconnection switch. A circuit breaker of the nominal value

1Ais a convenient circuit breaking device. Its function and position has to be clearly identified (symbols ‘0’

and ‘I’ acc. to IEC EN 61010-1). Internal power supply is galvanically isolated from internal circuits.

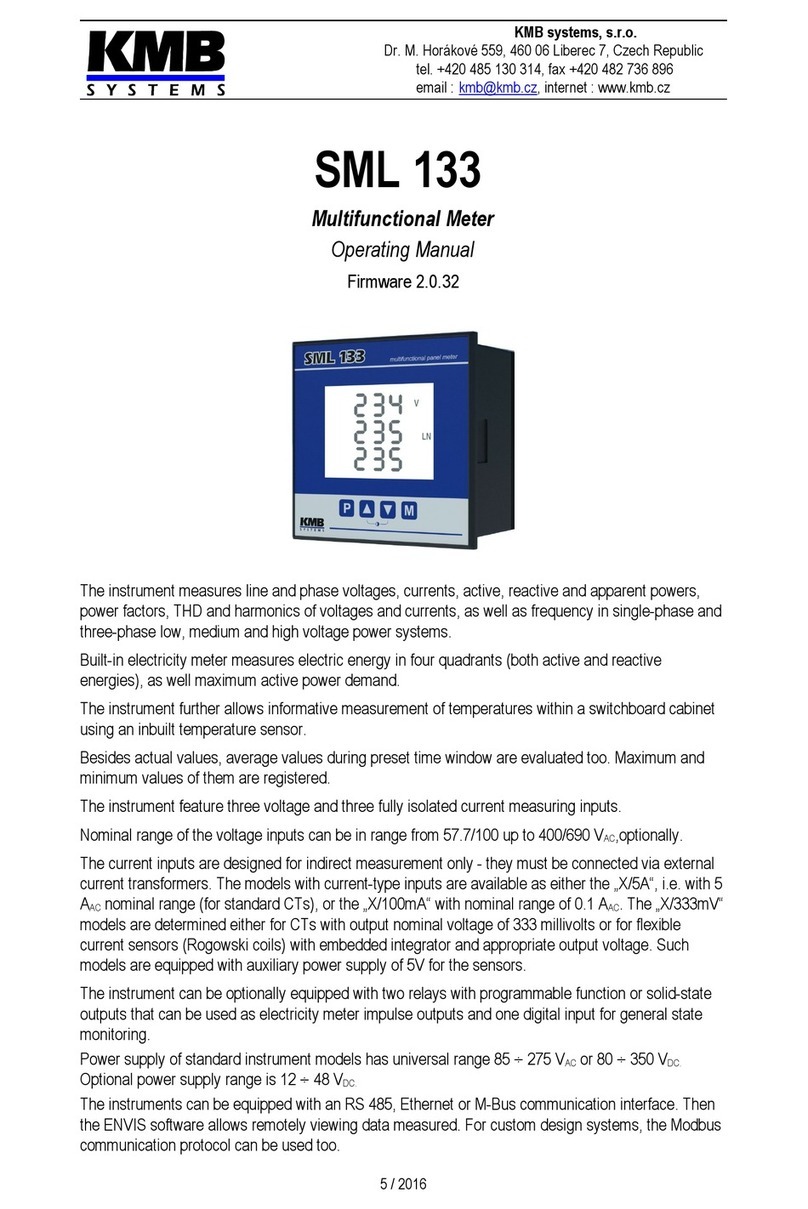

2.3.2 Measured voltage

The measured voltages are connected to the terminals L1, L2 and L3. Connect the neutral wire to the terminal

N. With delta or Aaron connections terminal N remains unused. Voltage measurement inputs are connected

with internal circuits over high impedance.

It is suitable to protect the measured voltage lines for example with 1A fuses of the required rating. Measured

voltages can also be connected via instrument voltage transformers. A connection cable maximum cross section

area is 2.5mm2for voltage terminals.

2.3.3 Measured currents

The instruments are designed for indirect current measurement via external CT only. Proper current signal

polarity (S1 or S2 terminals, k or l in the older notation) must be observed. You can check the polarity by the

sign of phase active powers on the instrument display, its web pages or in the ENVIS.Daq application.

X/5A current input option The current signals from 5A or 1A instrument current transformers must be con-

nected to the terminal pairs I11, I12, I21, I22, I31, I32 with a cable of maximum cross section area 2.5mm2and

a maximum length of 3 m.

X/100mA current input option The supplied current transformers (which are standard accessory) must be

clamped on measured wires with proper isolation and interconnected with corresponding terminal pairs I11,

I12, I21, I22, I31, I32 using a twisted-pair cable of maximum length of 3 m. The secondary winding of the

transformers is led to the screw terminals. The S1, S2 (or ”K“/”L“ and ”k“/”l“) orientation is marked on the CT

guide groove. A connection cable maximum cross section area is 1.5mm2.

Warning !: Connection of the common X/5A, X/1A or another unsupported current transformers to an

instrument with X/100mA option is strictly forbidden !!! The instrument can be seriously damaged!

2.3.4 Communication peripherals

All peripherals stated below are galvanically isolated from the rest of the instrument and from each other.

Ethernet interface (optional) 100 Mbit Ethernet interface with RJ-45 connector (100Base-TX) labeled as ETH

is situated on a top panel of the device. Ethernet interface can be used as substitution for the primary RS-485

for connection of the device to LAN and for easy connection of remote control PC.

RS-485 serial line serves usually as a remote communication for reading of actual data, archive downloading

and device configuration. Serial RS-485 line uses terminals A+, B- with shielding at terminal Gof COM1 block

(fig. 6). The end point of the communication line must be properly terminated with ˜120Ωresistor.

5