*

Archive Starts at, Immediately - Determines whether to begin recording immediately after the

instrument is powered on or at a preset day and time.

*

Archived Quantities - In this section you can choose the set of quantities that you want to record.

Column AVG tick the required quantity and a record will contain the average values per logging

interval. If you want to record the maximum and minimum values of the measuring cycle (see

explanation below) during the recording interval, check the appropriate box in column MIN,

MAX. The powers in column Import/Export can determine whether to store import and export

respectively inductive or reactive load sums separately.

*

Harmonics - You can choose voltage and/or current harmonics to be recorded. You can select

also, if only odd or all harmonics should be recorded and choose maximal harmonic order. Last

option enables angles of harmonics to be included in archives.

*

The dialog also shows the estimated capacity of the main archive with the actual configuration

(Estimated Record Time).

–Electricity Meter (fig. 5d) - For settings belonging to measurement of electrical energy. In addition

to two tariff, three-phase, four quadrant electric energy, this unit records the maximum and average

of active power.

*

Record Period - The period of recording of the electricity meter status (automatic meter reading).

*

Tariff Control - Set type of tariff control. You can choose from a tariff table or an external digital

input for tariff switching.

*

Tariff Table - This table can set a daily tariffs for three different prices per hour. The energy will

be registered separately for each tariff.

*

Currency Code - You can set a local currency code.

*

Conversion Rate - You can provide a cost of 1 kWh in different tariffs, so than you are able to

optionally see prices of an imported (or exported) energy in a local currency instead of direct

energy values.

*

Window Type, Window Length - Method of an averaging of the average active power PAVGMAX(E).

You can choose a fixed window (Fixed) or a floating window (Floating). In addition, you can set

the length of averaging window.

–Input/Output (fig. 5e) - The SMC 144 is always equipped with two alarm LEDs (LED A1,LED A2 )

and optionally one relay or impulse output (O1 ).

*

You can set a function, that controls each output by selecting the Standard output option. Com-

plex conditions can be set by using up to four events/conditions (E1 through E4 ), which can

be in conjunction and/or disjunction. Character of an output can be selected as Permanent or

Pulse. In the latter case, duration of the whole period and the active part of period can be set.

*

Also, you can set any output to behave as a standard electricity meter output by selecting the

Elmeter output option. In this case, you can select whether you want active or reactive energy

output and import or export. Also, number of pulses/kWh must be set properly.

To commit changes in any of the above parameters it is required to send these new values into the instrument

using the Send button. Settings can also be backed up into the file for later use with the Save button.

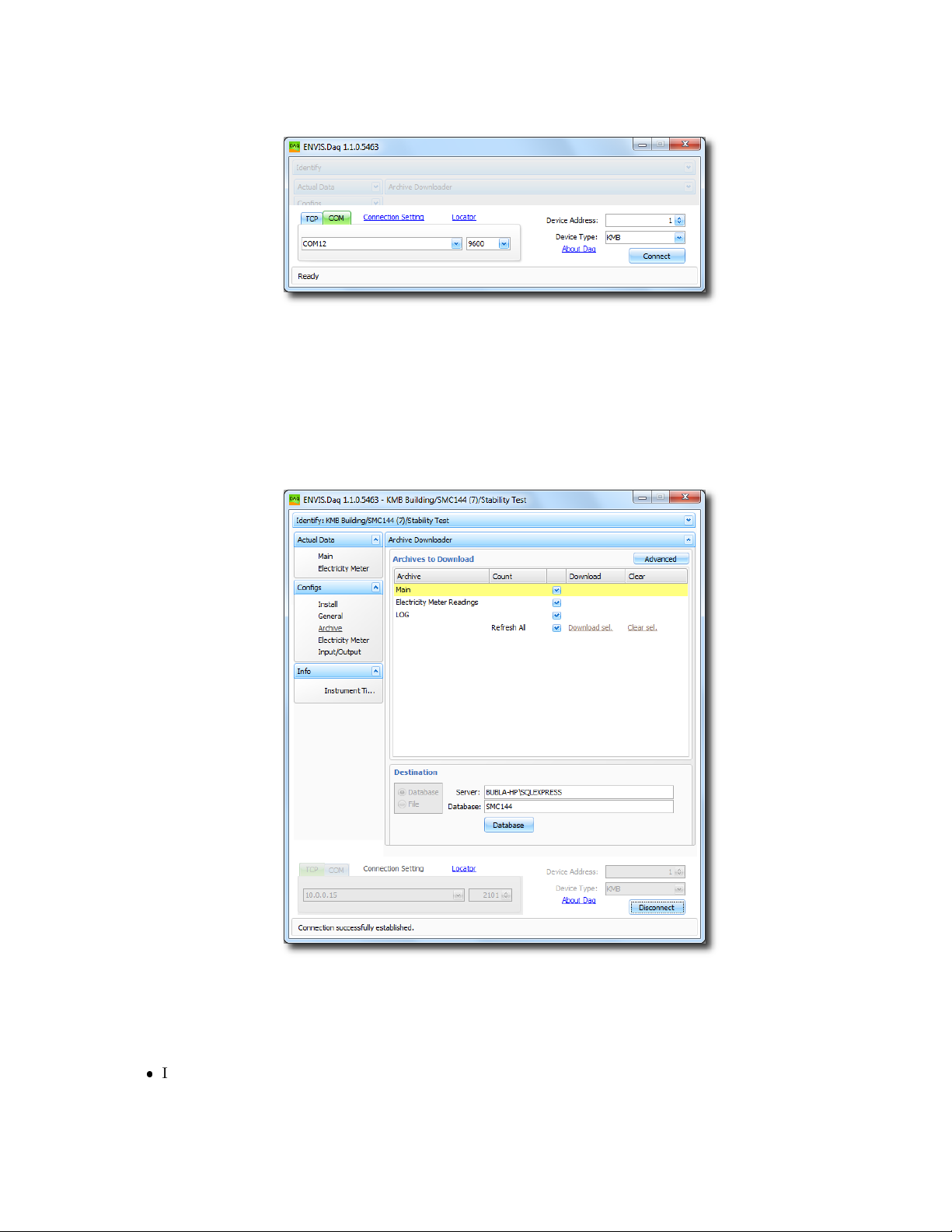

It is also recommended to check the status of the internal clock in the device. In the Info tab open the

Instrument Time window (figure 5f). The program reads the current time set in your device and displays it.

It also displays the difference to the actual PC time (Time Difference). If the time in the instrument varies

significantly, it can be adjusted by selecting the Set Time from the PC option.

The necessary crucial device settings is than done — disconnect the communication cable and SMC 144 is

ready to be connected to the measured network.

2.3 Installation

Natural air circulation should be provided inside the distribution board cabinet, and in the instrument’s neighbor-

hood, especially underneath the instrument, no other instrumentation that is source of heat should be installed

10