0900456 Rev: G (ECO 6537) Page 1 of 4

INTRODUCTION

The Knight Sani-Clean III is the perfect dispensing system for supermarket meat rooms, kitchen areas, bakeries,

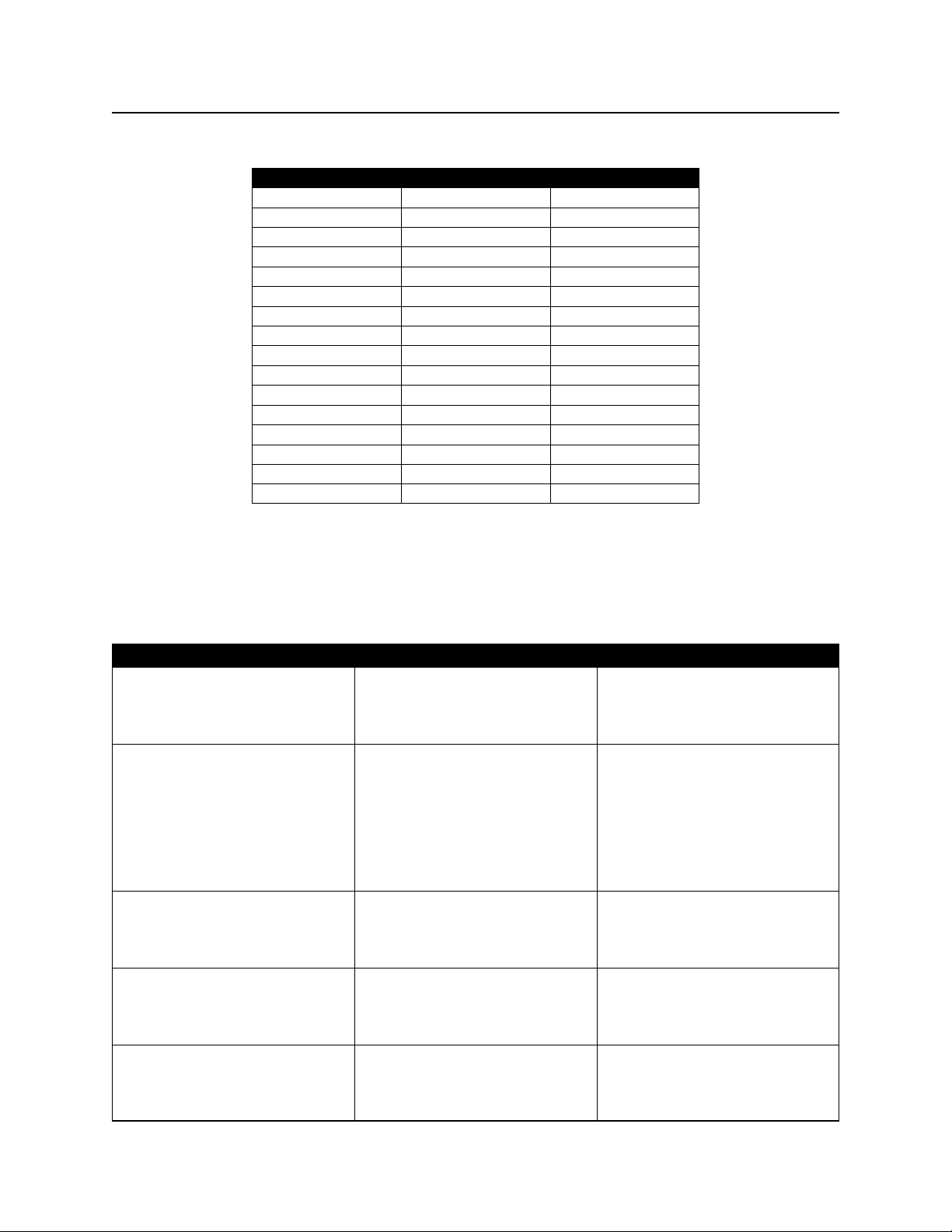

seafood stores, auto dealers, truck washing, loading docks, etc. The Knight Sani-Clean III is the economical system

for controlling cleaning costs. Chemicals are mixed accurately and consistently at your chosen dilution ratio, utilizing

two in-line venturi valves. Up to 16 different product concentrations are available using “screw-in” metering tips.

INSTALLATION

(1) Mount the unit to the wall using the screws and anchors provided.

(2) Mount the hose bracket to the wall using the screws and anchors provided.

(3) Select the appropriate metering tip (see chart on the following page) and screw into

end of barb fittings. The cover does not need to be removed to access the barb

fittings.

(4) Install foot strainer on the end of each supply tube. Slide a ceramic weight over

each supply tube, then connect the tube onto the barbed fittings. Cinch a plastic tie

wrap (provided) around the connection to secure. Insert foot end into container.

(5) Connect to a water supply using the provided 3/4" garden hose adapter on the left

side of the unit — the adapter can be removed to permit hard plumbing directly to

3/8" or 1/2" NPT water line. Water pressure should be 30 to 80 PSI. Water

temperature should not exceed 140 degrees (F).

(6) Attach the nozzle to the end of the output hose, then connect the hose to the fitting on the bottom of the

unit.

OPERATION

(1) Turn on desired supply valve, Detergent, Rinse, or Sanitizer, and depress spray nozzle handle. The selected

product and water mixture will be dispensed.

(2) To use the Foam feature, attach the Foam Wand to the quick-connect coupling on the end of the nozzle (be sure

air intake holes are not obstructed) and depress spray nozzle handle.

IMPORTANT NOTES

ONLY USE A HOSE AND SPRAY NOZZLE SUPPLIED BY KNIGHT LLC.

DO NOT ADJUST THE KNOB ON THE SPRAY NOZZLE FROM THE FULL SPRAY POSITION.

DO NOT OPERATE MORE THAN ONE PRODUCT VALVE AT A TIME, AS PRODUCT DILUTION RATES WILL

NOT BE ACCURATE.

UNIT SUPPLIED WITHOUT A BACKFLOW PREVENTION DEVICE. TO PREVENT POSSIBLE CHEMICAL

BACKUP INTO THE WATER SUPPLY, COMPLY WITH ALL LOCAL PLUMBING CODES AND INSTALL AN

APPROPRIATE BACKFLOW PREVENTION DEVICE.

SANI-CLEAN III

INSTRUCTION MANUAL

Step 6

Step 5