SEN-86../87..

page 8 SEN-86../87.. K04/0618

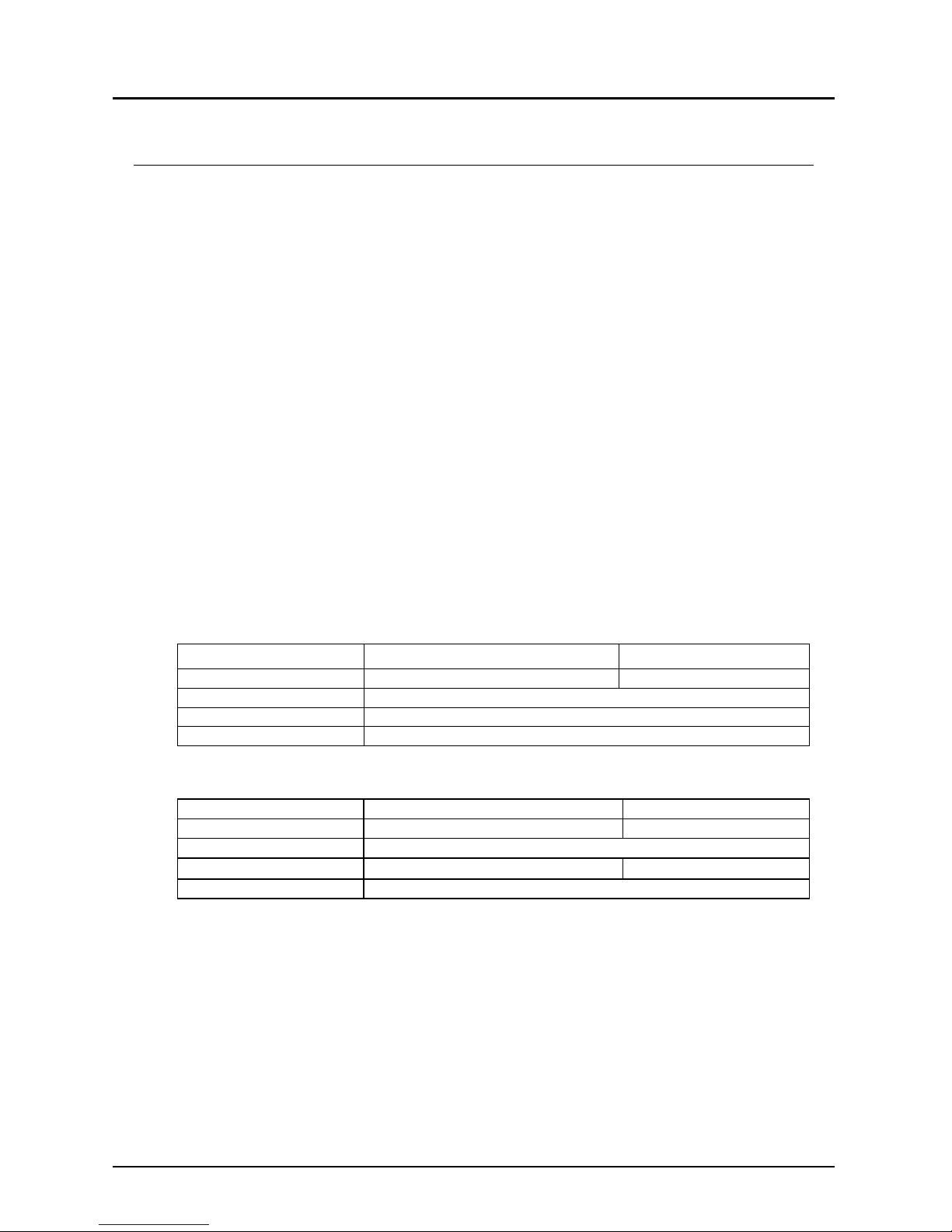

10.Technical Information

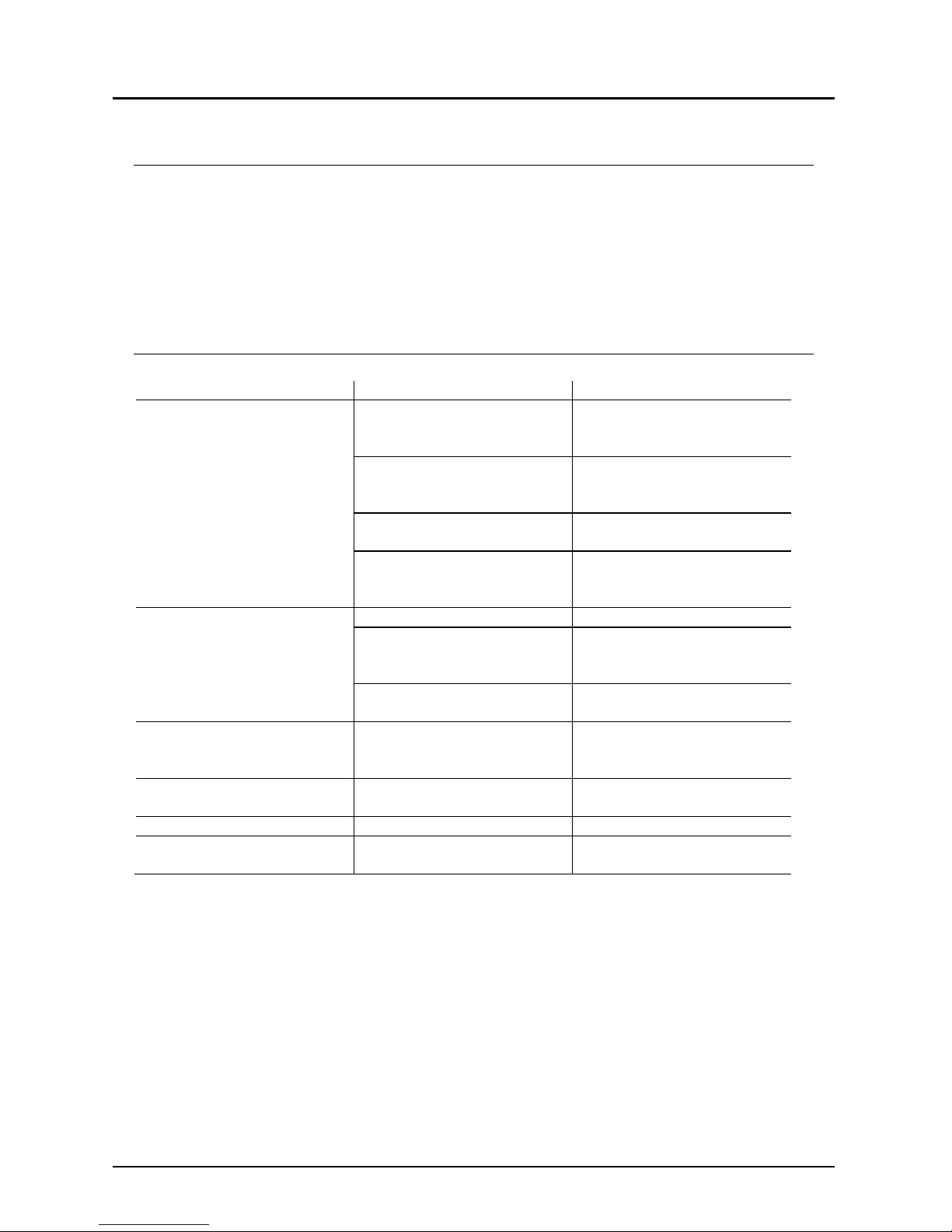

Model SEN-86x0 SEN -87x0

Technology internal diaphragm

Pressure type gauge pressure

Housing stainless steel 1.4305

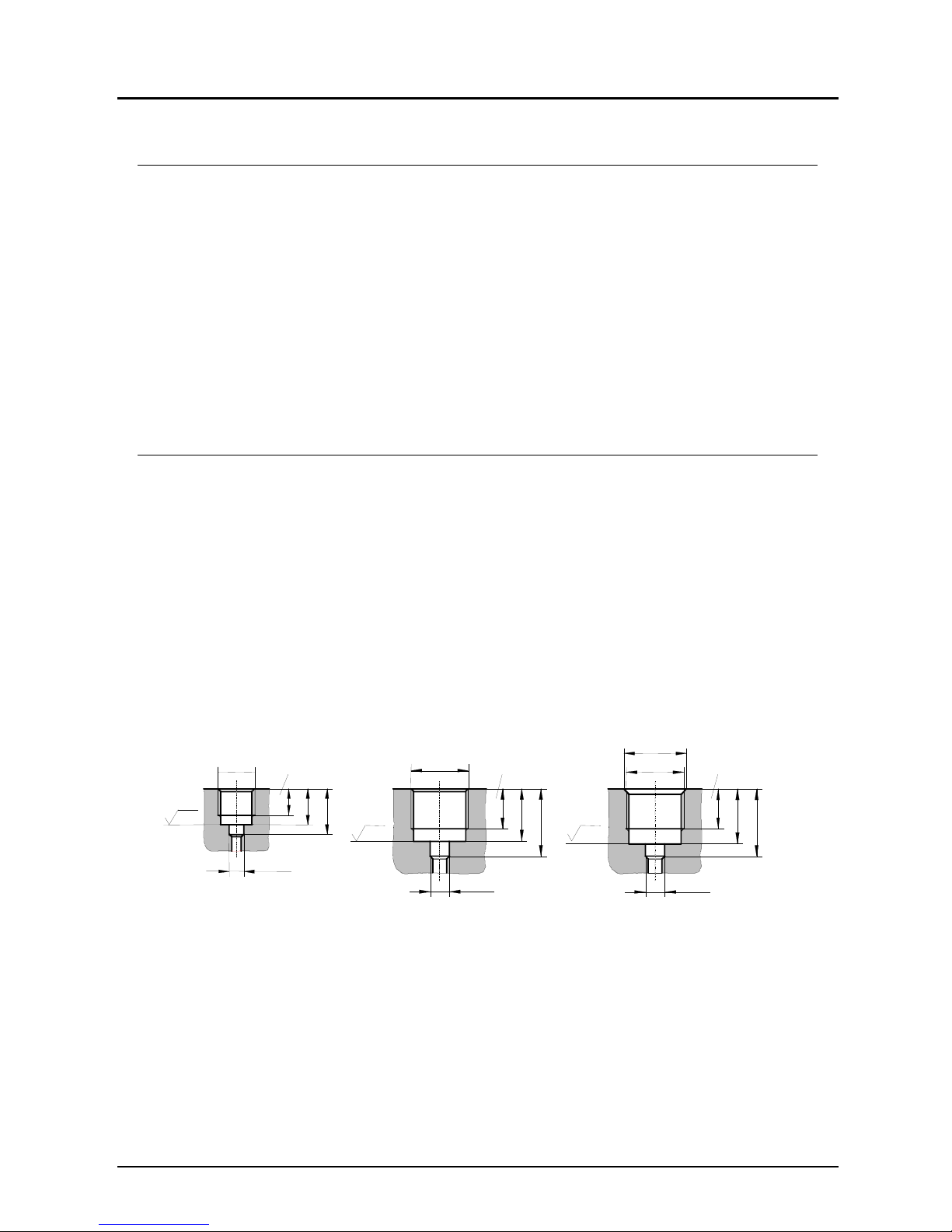

Connection: G ½ male; stainless steel

1.4301 (NPT, UNF on

request)

G ¼ male; stainless steel

1.4301 (NPT, UNF on

request)

Sensor element ceramic (Al2O3)

Measuring principle thick film techn. (DMS)

O-Ring NBR

Max. Temperature Storage: -30...+100 °C

Medium: -20...+125 °C

Ambient: -30...+100 °C

Storage: -30...+100 °C

Medium: -20...+ 85 °C

Ambient: -30...+100 °C

Pressure limitation < 60 bar: 2 x range

≥60 bar: 1.5 x range

Accuracy class 0.5 f.s.d.)

Repeatability ± 0.15 % (f.s.d.)

Characteristic deviation ± 0.3 % (f.s.d.)

Stability (annual) ± 0.2 % of full scale

in rated conditions

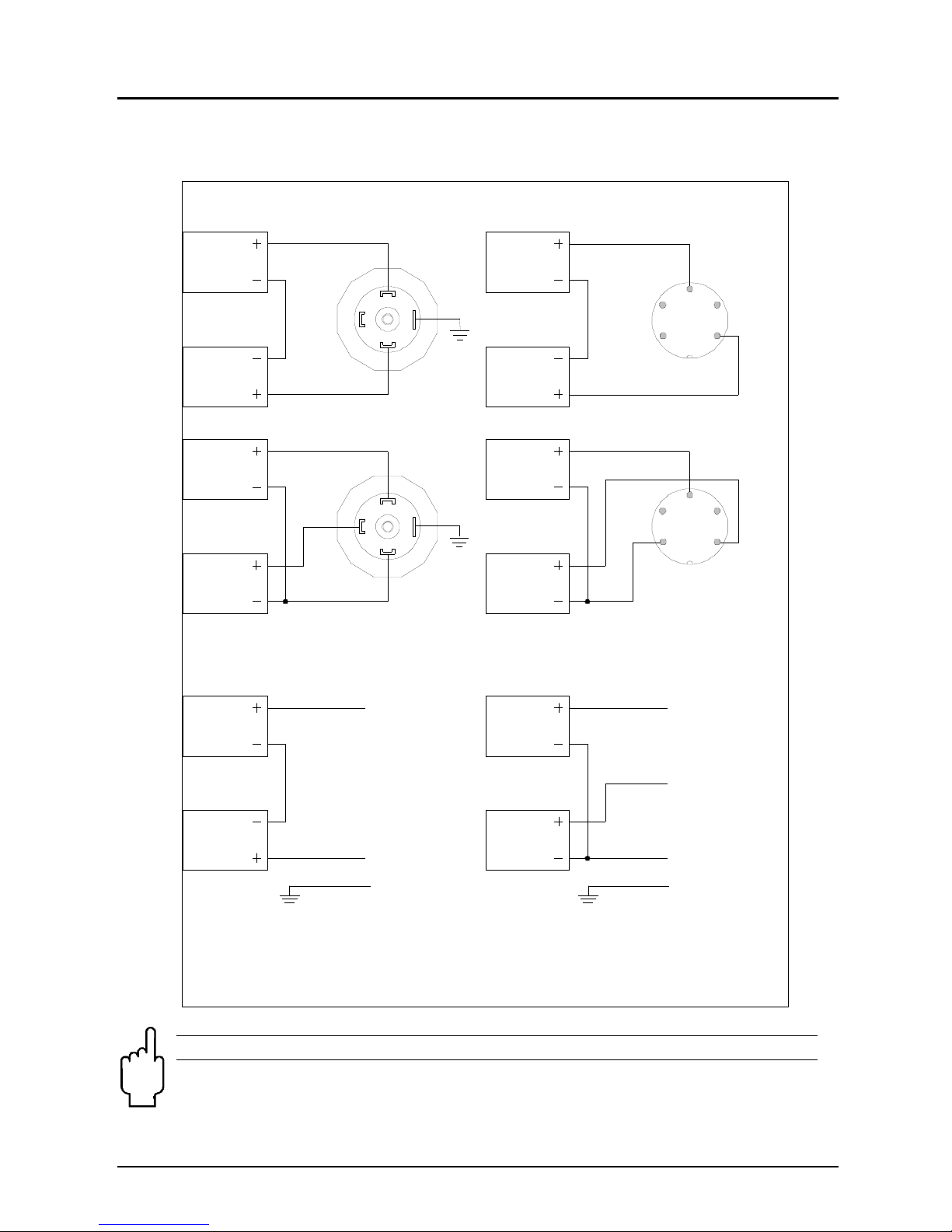

Electrical connection Plug DIN 43 650 A / Plug M12x1

Cable connection

Power supply 15...32 VDC

Output signal 4 – 20 mA, (2-wire), 0 – 10 VDC

Load () (UB– 15 V)/0.02 A (for 4 – 20 mA)

Response time 1 ms (within 10 – 90% of full scale)

Temp. comp. range -25...+85 °C

Temperature drift Zero:

± 0.02% full scale/K

Measuring span:

± 0.01% full scale/K

Protection IP 65 (SEN-860..; SEN-863..)

IP 68 (SEN-865..)

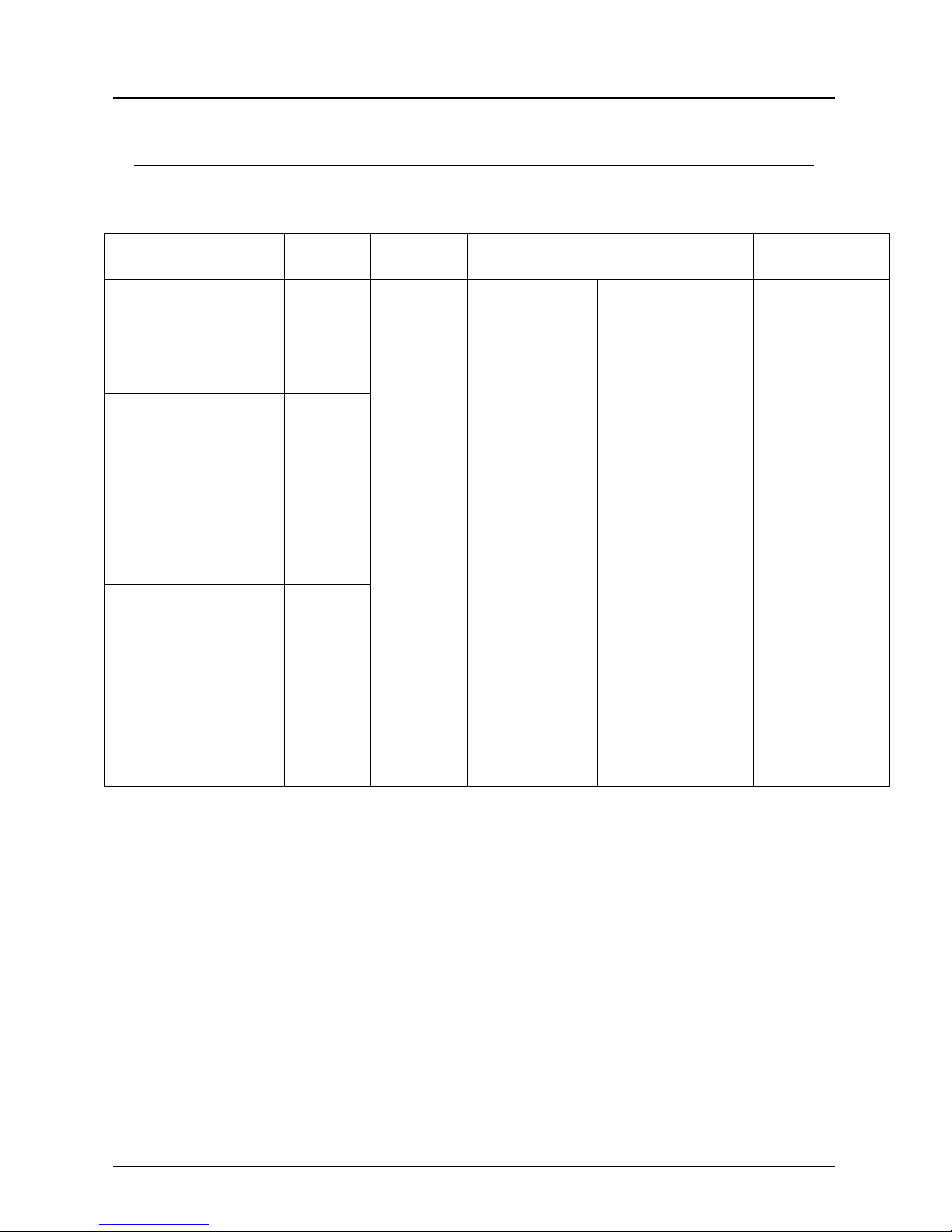

Options Absolute pressure for ranges 1.0...25 bar

Oil- and free of grease for oxygen

Silicone- and LABS free

Connection with 50 mm cooling fins tmax 125 °C

Connection and housing SS 1.45391) instead of 1.4305

Connection and housing SS 1.4571 instead of 1.4305

O-ring FPM instead of NBR

O ring PTFE (Kalrez) instead of NBR <100 bar

½” NPT thread instead of “G” G¼ DIN385-E inclusive seal

ring3)

Special connection2) on request

1) Seawater resistant

2) Please specify in writing

3) Adapter of PSD usable