III

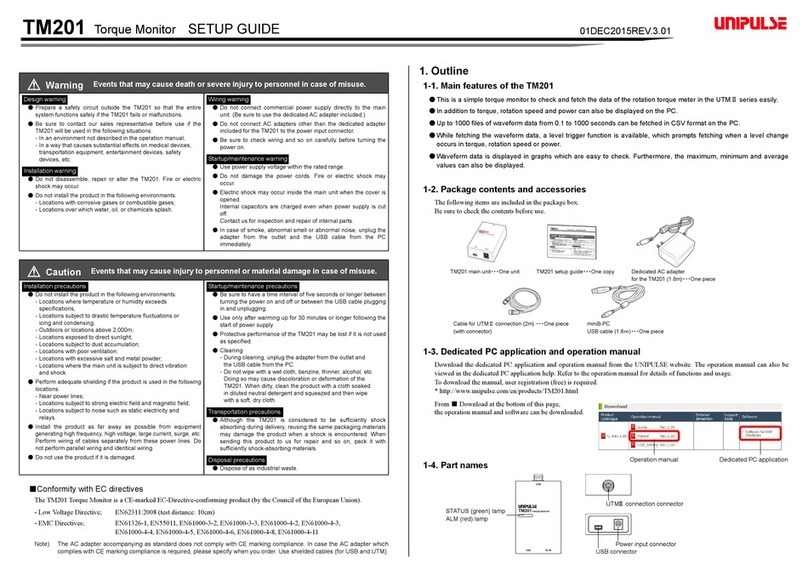

Caution

●The F340A must be incorporated into the control panel and so forth.

●Do not install into the following environments:

- Locations where temperature or humidity exceeds specifications;

- Locations subjected to drastic temperature fluctuations or icing and condensing;

- Outdoors or locations above 2,000m;

- Locations exposed to direct sunlight;

- Locations subject to dust accumulation;

- Locations with poor ventilation;

- Locations with a lot of salt and metal powder;

- Locations where the main unit is subject to direct vibration and shock.

●Perform adequate shielding if the indicator is used in the following locations:

- Near power lines;

- Locations subject to strong electric field and magnetic field;

- Locations subject to noise such as static electricity and relays.

●Install as far away as possible from equipment generating high frequency, high voltage,

large current, surge, etc. Perform wiring of cables separately from these power lines. Do not

perform parallel wiring and identical wiring.

●Do not use the indicator if damaged.

●Tighten power input terminal screws to the torque specified.

Loose tightening may cause short-circuiting, fire, or malfunction.

Tightening torque: 0.5N・m

●Use shielded cables for cables (sensors, external I/O, options).

●The temporary overvoltage applied to the power should not exceed 1500V.

●Be sure to have a time interval of five seconds or longer between turning power on and off.

●Use after warming up for 30 minutes or longer following the startup of power supply.

●Protective performance of the F340A may be lost if it is not used as specified.

●Care

- Unplug the power supply during maintenance.

- Do not wipe with a wet cloth, benzin, thinner, alcohol, etc. Doing so may cause

discoloration or deformation of the F340A.

When dirty, clean using a cloth soaked in diluted neutral detergent followed by a soft, dry

cloth.

Events that may cause injury to personnel or

material damage in the event of misuse.

Startup/maintenance precautions