TABLE OF CONTENTS

INTRODUCTION............................................................................................................................................................4

SAFETY.........................................................................................................................................................................5

INSPECTION.................................................................................................................................................................6

PRE-INSTALLATION INSPECTION .........................................................................................................................6

OIL FILL QUANTITY/TYPE.......................................................................................................................................6

PUMP INSTALLATION .............................................................................................................................................7

POSITIONING THE PUMP .......................................................................................................................................7

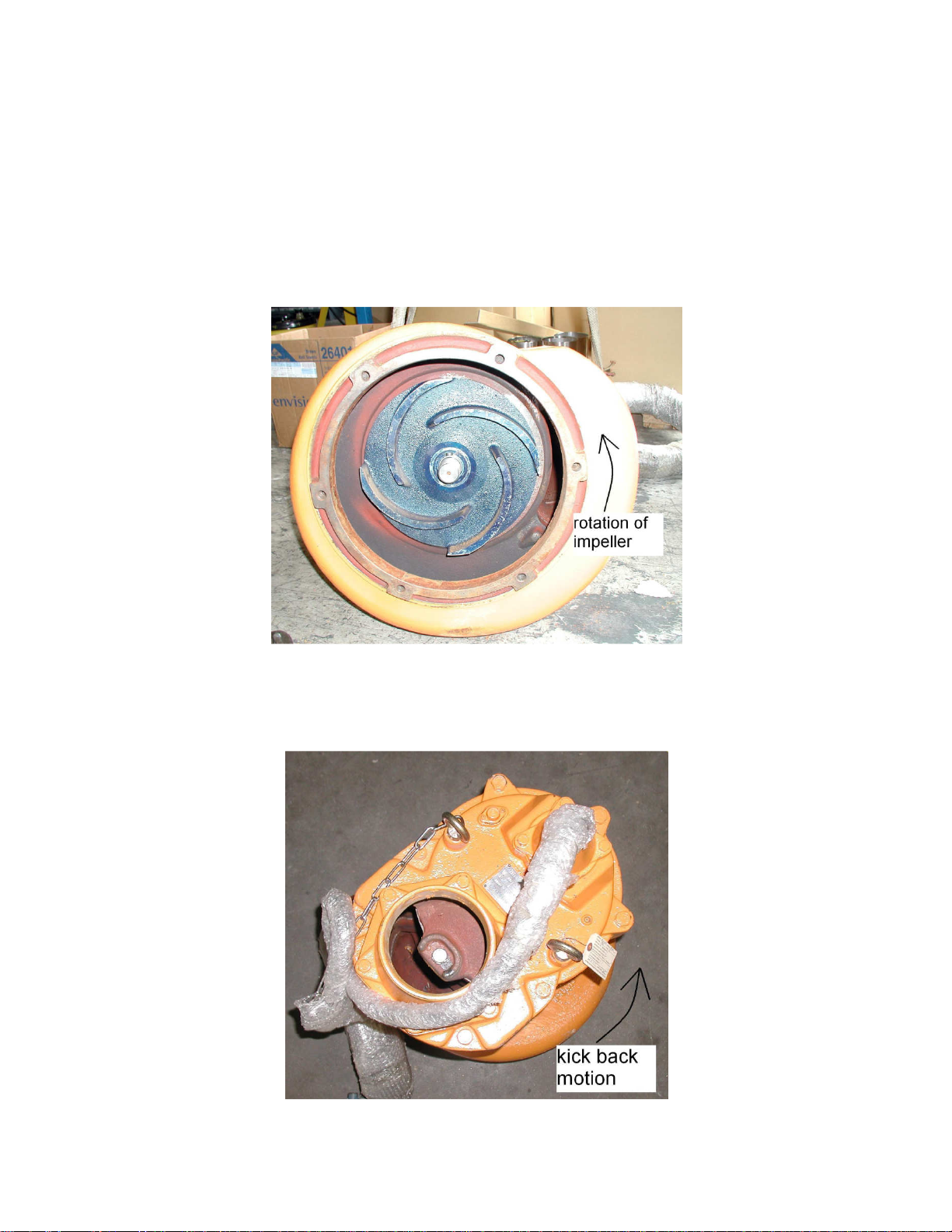

PUMP ROTATION ....................................................................................................................................................8

PUMP OPERATION.......................................................................................................................................................9

TYPICAL MANUAL DEWATERING INSTALLATION.....................................................................................................9

STOPPING..............................................................................................................................................................10

TYPICAL AUTOMATIC DEWATERING INSTALLATION ............................................................................................10

AUTOMATIC OPERATION.....................................................................................................................................10

STOPPING..............................................................................................................................................................11

INTENDED METHODS OF CONNECTION.................................................................................................................11

SINGLE PHASE WIRING INSTRUCTIONS............................................................................................................12

TROUBLE SHOOTING................................................................................................................................................13

PUMP WILL NOT RUN ...........................................................................................................................................13

PUMP RUNS BUT DOES NOT DELIVER RATED CAPACITY...............................................................................13

SERVICING YOUR SUBMERSIBLE PUMP............................................................................................................13

MAINTAINING YOUR PUMP..................................................................................................................................14

CHANGING SEAL OIL............................................................................................................................................14

DIMENSIONAL DRAWING .....................................................................................................................................15

MODEL: PSP125ABK CURVE................................................................................................................................16

MODEL: PSP200SSK CURVE................................................................................................................................16

EXPLODED VIEW OF PWP125ABK...........................................................................................................................17

EXPLODED VIEW OF PSP200SSK............................................................................................................................18

PSP SERIES PARTS LIST ..........................................................................................................................................19

SINGLE PHASE WIRING DIAGRAM 115V (PSP125SSK / PSP200SSK)...................................................................20

WARRANTY AND LIMITATION OF LIABILITY............................................................................................................21

NOTES:........................................................................................................................................................................22