K4304X High Temperature 'Sequence IV' Liquid Foam Test Bath

Operation and Instruction Manual

K4304X-Manual -4-

2 Safety Information and Warnings

Safety Considerations. The use of this

equipment may involve hazardous materials and

operations. This manual does not purport to

address all of the safety problems associated with

the use of this equipment. It is the responsibility of

any user of this equipment to investigate,

research, and establish appropriate safety and

health practices and determine the applicability of

regulatory limitations prior to use.

Equipment Modifications and Replacement

Parts. Any modification or alteration of this

equipment from that of factory specifications is not

recommended voids the manufacturer warranty,

product safety, performance specifications, and/or

certifications whether specified or implied, and

may result in personal injury and/or property loss.

Replacement parts must be O.E.M. exact

replacement equipment.

Unit Design. This equipment is specifically

designed for use in accordance with the applicable

standard test methods listed in section 1.2 of this

manual. The use of this equipment in accordance

with any other test procedures, or for any other

purpose, is not recommended and may be

extremely hazardous.

Chemical Reagents Information. Chemicals and

reagents used in performing the test may exhibit

potential hazards. Any user must be familiarized

with the possible dangers before use. We also

recommend consulting the Material Data and

Safety Sheet (MSDS) on each chemical reagent

for additional information. MSDS information can

be easily located on the internet at

http://siri.uvm.edu or http://www.sigma-

aldrich.com.

3 Getting Started

The instructions for preparing the equipment

assume that the user is aware of the contents of

this document, which lists the warranty conditions

and important precautions.

3.1 Packing List

K4304X High Temperature 'Sequence IV' Liquid

Foam Test Bath including:

- (2) 1000mL Test Cylinders (K43012)

- (2) Calibrated and Certified Stainless Steel

'Mott' Diffuser Stones (344-005-01C)

- (2) Air Delivery Tube Assemblies (K430-3A)

- (2) Air Outlet Tubes (K430-0-13)

- (2) Rubber Stoppers (K430-0-8)

- (1) 12 x 18 Pyrex Bath Jar (332-001-003)

- (1) 18” Safety Shield (K23425-00000)

- (1) Test Tube Rack (K43002-0-13)

K4304X-Manual High Temperature 'Sequence

IV' Liquid Foam Test Bath Operation and

Instruction Manual

3.2 Unpacking

Carefully unpack and place the instrument and

accessories in a secure location. Use extra care

while unpacking the Borosilicate Glass bath jar.

Ensure that all parts listed on the packing list are

present. Inspect the unit and all accessories for

damage. If any damage is found, keep all packing

materials and immediately report the damage to

the carrier. We will assist you with your claim, if

requested. When submitting a claim for shipping

damage, request that the carrier inspect the

shipping container and equipment. Do not return

goods to Koehler without written authorization.

3.3 Setup

Equipment Placement. Place the base on a firm,

level table in an area with adequate ventilation or

in a hood. The unit may be leveled by making

minor turning adjustments to the feet located at

the base of the unit. Please note that Koehler does

not supply a level with this equipment.

Install the borosilicate glass test jar. Fill the jar with

appropriate bath medium as per ASTM D6082.

Please see section 5.1 for further details on the

bath medium.

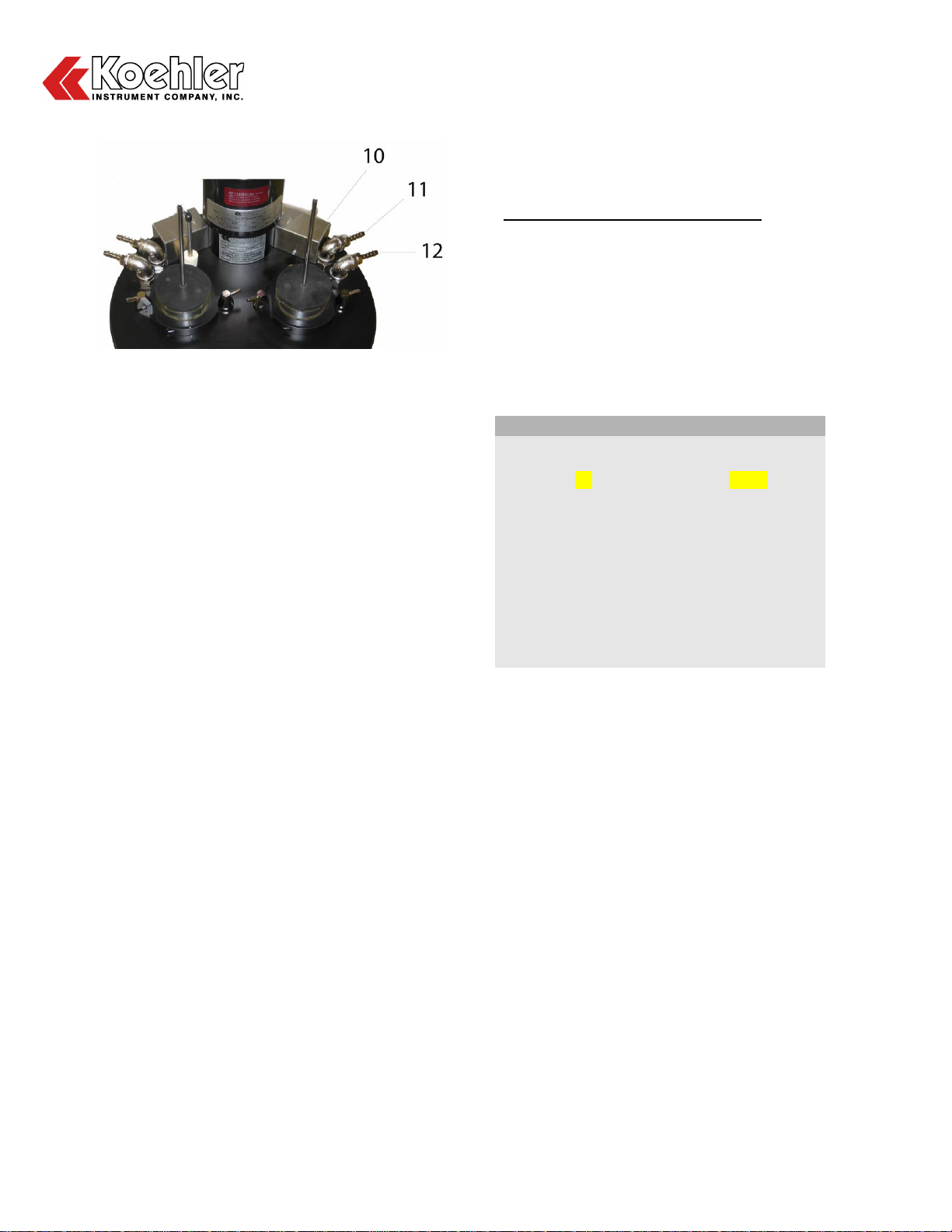

Install the bath top assembly on the jar and plug

the control cables into the receptacle on the base

unit.