- 3 -

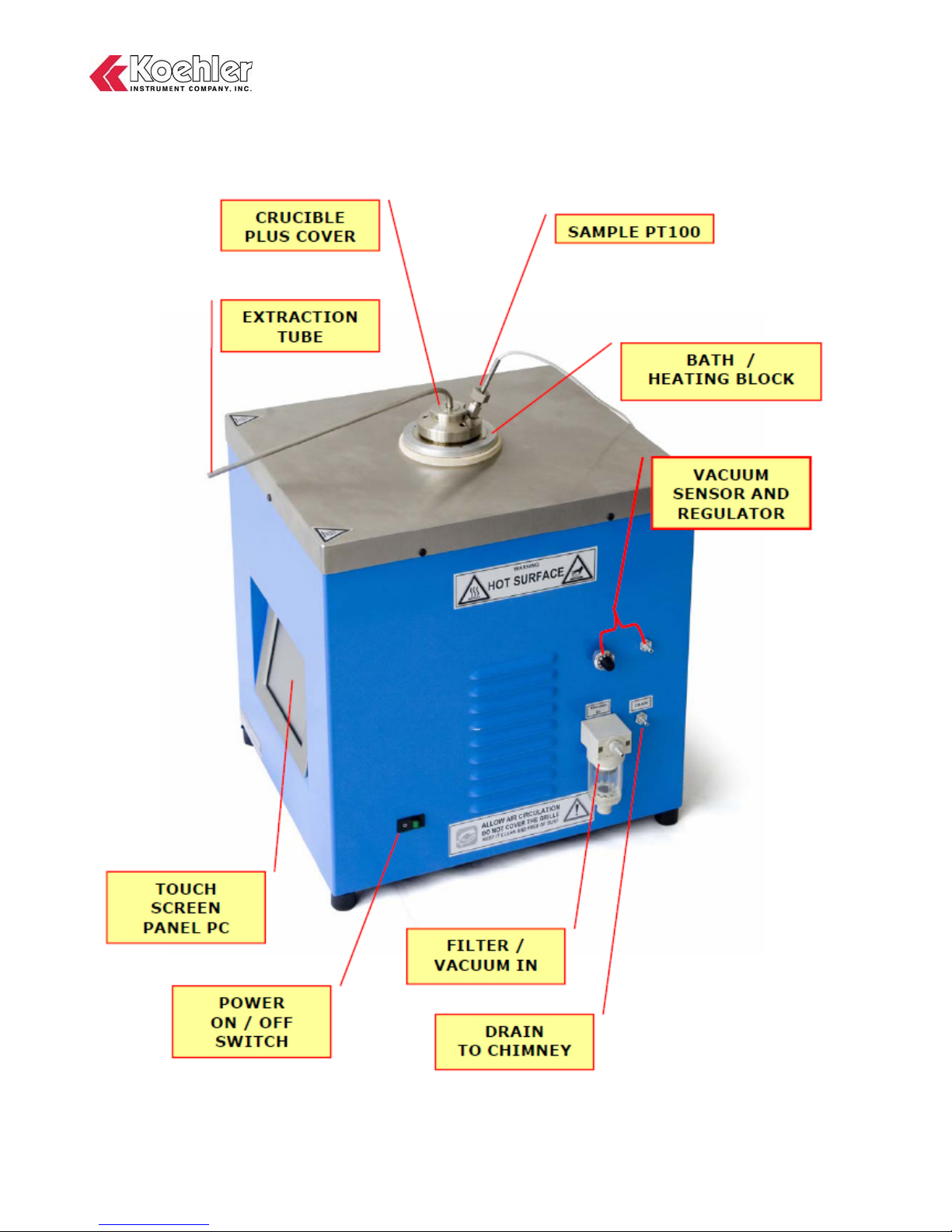

1 Introduction

The Automatic Non-Woods Metal Noack

Evaporative Apparatus tests for the evaporation loss

tendencies of lubricating oils at temperatures of up to

275°C. The newly designed electrically heated

aluminum block allows for testing without the use of

hazardous Woods Metal. The Noack tester is

equipped with an Electronic regulator allowing for

automatic control of temperature and differential

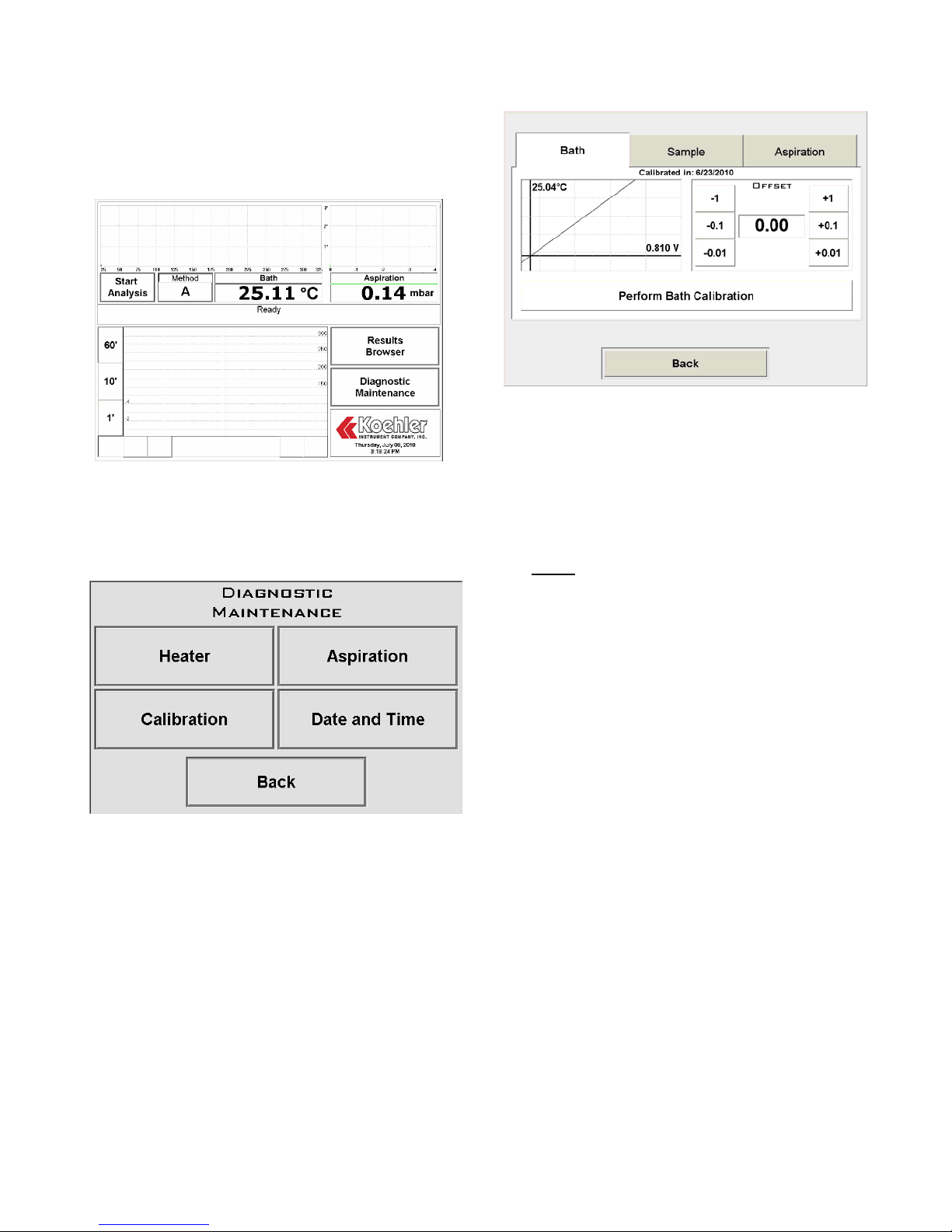

pressure. The system is managed by an integrated

6.5” Touch Screen Panel PC by means of the Noack

Evaluation Software run by a Windows® based

operating System. The Evaluation Software is

capable of recording all analytical parameters,

allowing for user customizable parameters, methods

and result reports as well as printing graphs and test

results.

• Conforms to ASTM D5800, Procedure B

• 6.5” Integrated Touch Screen Panel PC

• Integrated Vacuum Pump with automatic electronic

control system

• Direct sample temperature measurement via

PT100 probe

• Equipped with high resistant Kalrez valve, inlet filter

to remove product residuals

• USB port for connection to an external printer

and/or external PC

• Storage capacity for more then 60,000 analysis

• CE Marked

This manual provides important information

regarding safety, technical references, installation

requirements, operating condition specifications,

user facility resource requirements, and operating

instructions for the Automatic Non-Woods Metal

Noack Evaporative Apparatus. This manual should

also be used in conjunction with applicable published

laboratory procedures. Information on these

procedures is given in section 1.2.

1.1 Koehler’s Commitment to Our

Customers

Providing quality testing instrumentation and

technical support services for research and testing

laboratories has been our specialty for more than

50 years. At Koehler, the primary focus of our

business is providing you with the full support of

your laboratory testing needs. Our products are

backed by our staff of technically knowledgeable,

trained specialists who are experienced in both

petroleum products testing and instrument service

to better understand your requirements and

provide you with the best solutions. You can

depend on Koehler for a full range of accurate and

reliable instrumentation as well as support for your

laboratory testing programs. Please do not

hesitate to contact us at any time with your

inquiries about equipment, tests, or technical

support.

Toll Free: 1-800-878-9070 (US only)

Tel: +1 631 589 3800 • Fax: +1 631 589 3815

Email: info@koehlerinstrument.com

http://www.koehlerinstrument.com

1.2 Recommended Resources and

Publications

1. American Society for Testing and Materials

(ASTM)

100 Barr Harbor Drive

West Conshohocken, Pennsylvania 19428-

2959, USA

Tel: +1 610 832 9500 • Fax: +1 610 832 9555

http://www.astm.org • email: service@astm.org

ASTM Publication:

ASTM D5800: Standard Test Method

Evaporation Loss of Lubricating Oils by

the Noack Method

2. Energy Institute (IP)

61 New Cavendish Street

London, WIM 8AR, United Kingdom

Tel: 44 (0)20 7467 7100

Fax: 44 (0)20 7255 1472

http://www.energyinstpubs.org.uk/

IP Publication:

IP 421