OVERLOAD PROTECTOR

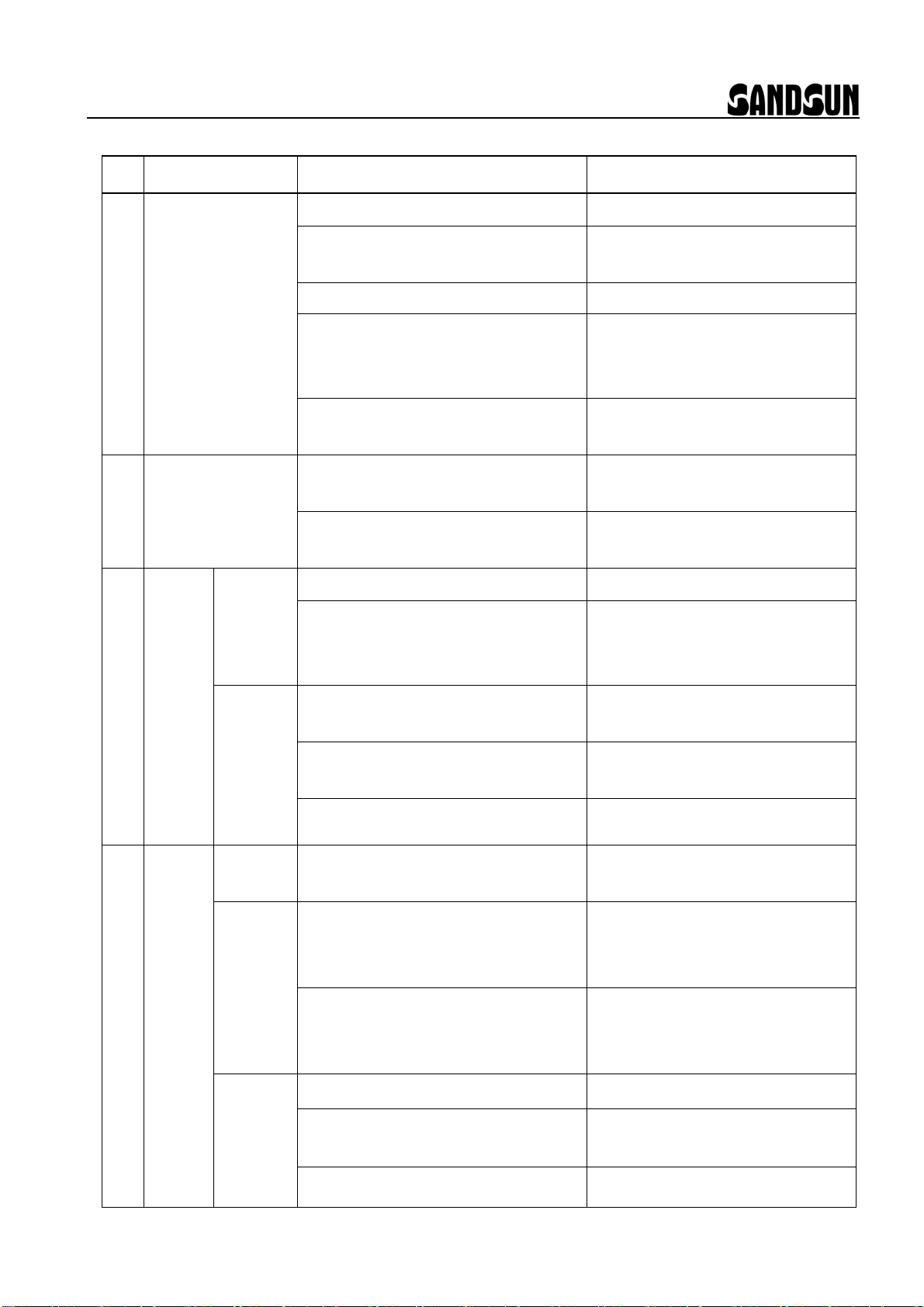

4. Basis of Selection:

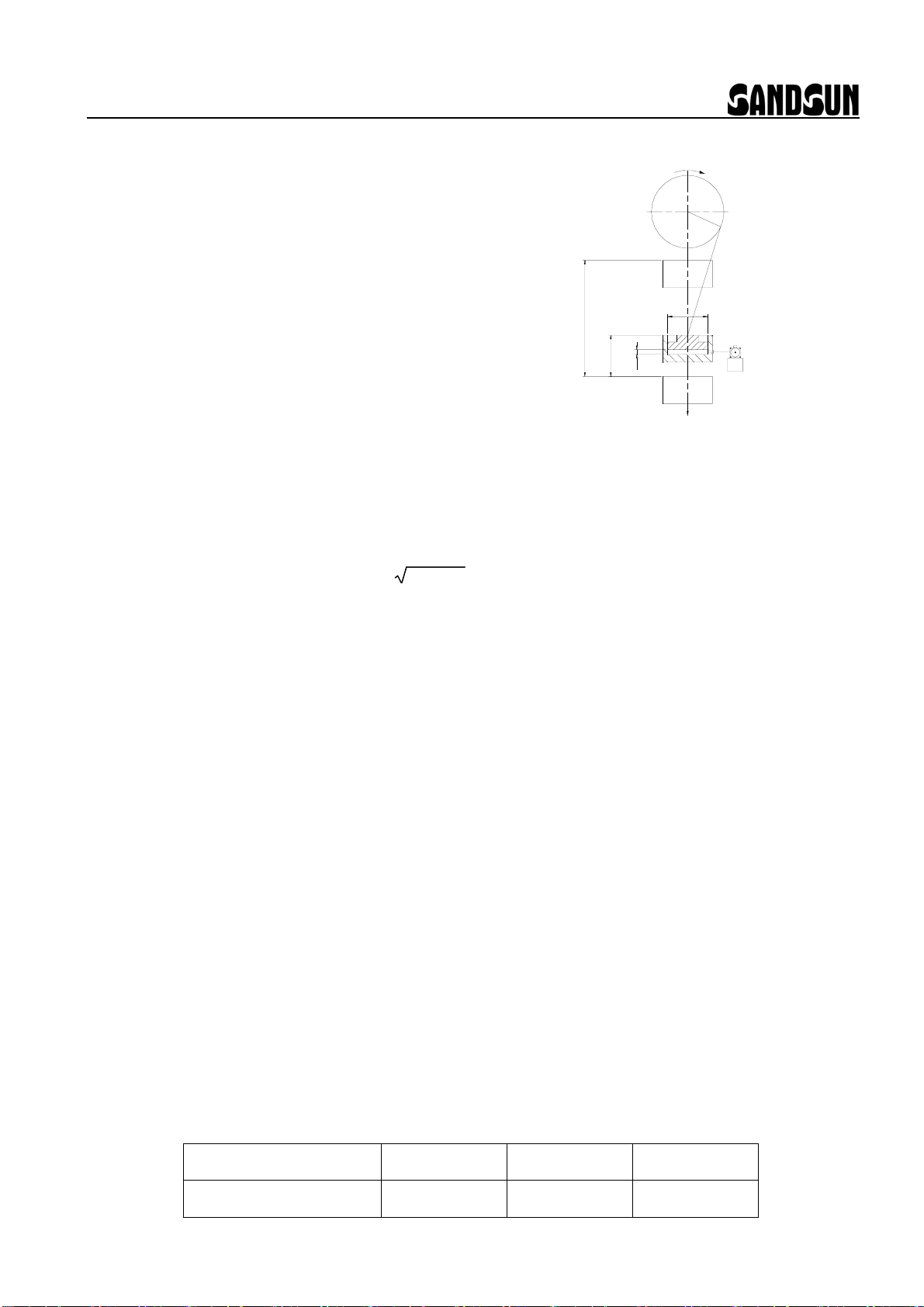

4.1 Specification & parameter of press

F:capacity of press (tons)

S:stroke length of slide (mm)

N:strokes per minute (spm)

H:rated tonnage point (mm)

D:diameter of cylinder inside slide (cm)

n:number of cylinder inside slide (pc)

h:stroke length of cylinder inside slide (cm)

Pa: air pressure (kgf/cm2)

m : times of air pressure

4.2 Calculation formulas for model selection

˙Total area of cylinder inside slide A=(πD2 / 4) x n (cm2)

˙Setting hydraulic pressure of overload protector P = Fx 1000 x 1.1 / A (kgf/cm2)

˙Setting air pressure of overload protector Pa=P / m (kgf/cm2)

˙Drop speed of slide V=N SH-H2 / 87.5 (cm/sec)

˙Releasing flow rate of cylinder inside slide when overload occurs Q=A x V (cm3/sec)

˙Volume of oil tank L ≧ 4 x A x h (cm3)

4.3 Determination of model no.

˙ Please choose a suitable model from below table according to releasing flow rate of cylinder

inside slide (Q)

˙ Releasing flow rate of overload protector which you choose has to be more than of cylinder

inside slide when overload occurs. (Please consider use two sets of overload protector if

releasing flow rate is not enough. It’s equal to 2 times of releasing flow rate)

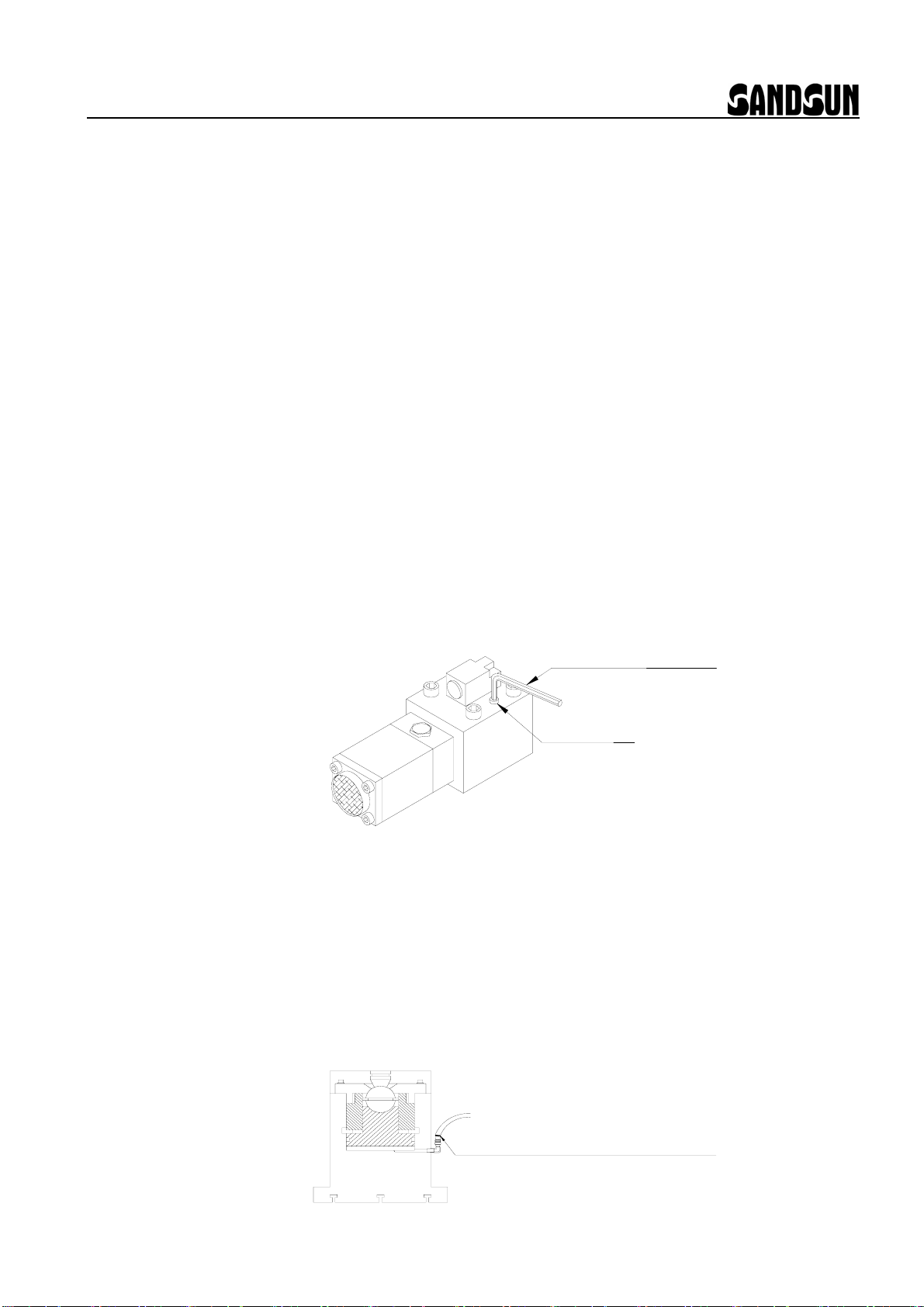

5. Attention Points for Piping:

5.1 Air piping:

a. Inside diameter of air piping has to be more than 6 mm.

b. Air supply has to remove steam and keep dry, in order to avoid generate furring.

The function of pump and other parts will be affected or damaged by furring.

c. Please choose normal close type (NC) of air solenoid valve either 2-way or 3-way

to use.

5.2 Hydraulic piping:

a. 1 In order to prevent normal function of overload protector or damage to inside parts

from dust or chips, Hydraulic piping & fitting has to be cleared completely and keep clean.

b. Size of piping for reference:

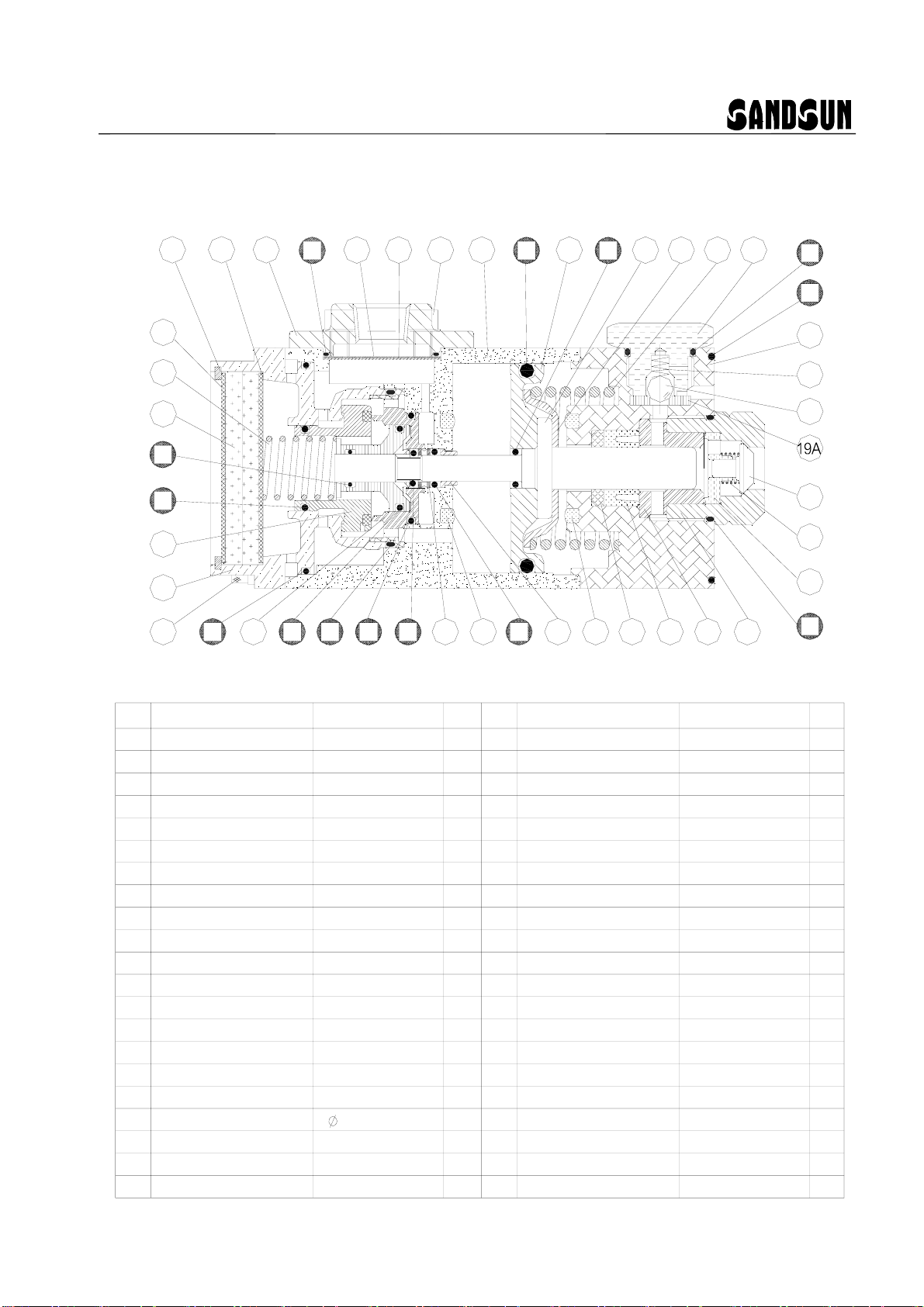

SANDSUN 2

Size (I.D. / O.D.) 12 / 18 mm 13 / 18 mm 14 / 18 mm

Work pressure (max.) 400 kgf/cm2 320 kgf/cm2 250 kgf/cm2

N

D

S

Hh

OVERLOAD

F