2TT-1757 7/18

Note: If the personality disk is NOT available, request

a replacement from the manufacturer using the

generator set serial number or order number.

DUser parameters unique to an installation include

timer values, setpoints, generator set data such as

voltage and input/output selections. These

parameters are typically set up for or by the installer at

the time of installation. User parameters are typically

recorded on the personality profile disk, a separate

backup disk/drive, or written in the Programmer-

Defined Settings appendix in the controller operation

manual. A copy of the Programmer-Defined Settings

form is included at the end of this document.

Note: If the user parameters are included on the

personality disk, the disk label should indicate

Site Program—Yes.

Read the entire installation procedure and compare the

kit parts with the parts list in this publication before

beginning installation. Perform the steps in the order

shown.

Always observe applicable local and national electrical

codes.

Note: The following service kit procedure changes only

the controller. If the generator set requires

voltage reconnection and/or frequency

adjustment, see the controller operation manual.

Installation Requirements

The following items are necessary PC requirements for

installing the controller service replacement kits.

DSiteTechtSoftware from the Kohler Power

Resource Center (KPRC). Go to Service Support and

click on Software to download to your PC hard drive, if

not already installed on your PC.

DTP-6701 SiteTechtSoftware Operation Manual

available from the literature section in Kohler Power

Resource Center (KPRC).

DUSB Cable with male USB-A and mini-B connectors.

See TP-6701.

Safety Precautions

Observe the following safety precautions while installing

the kit.

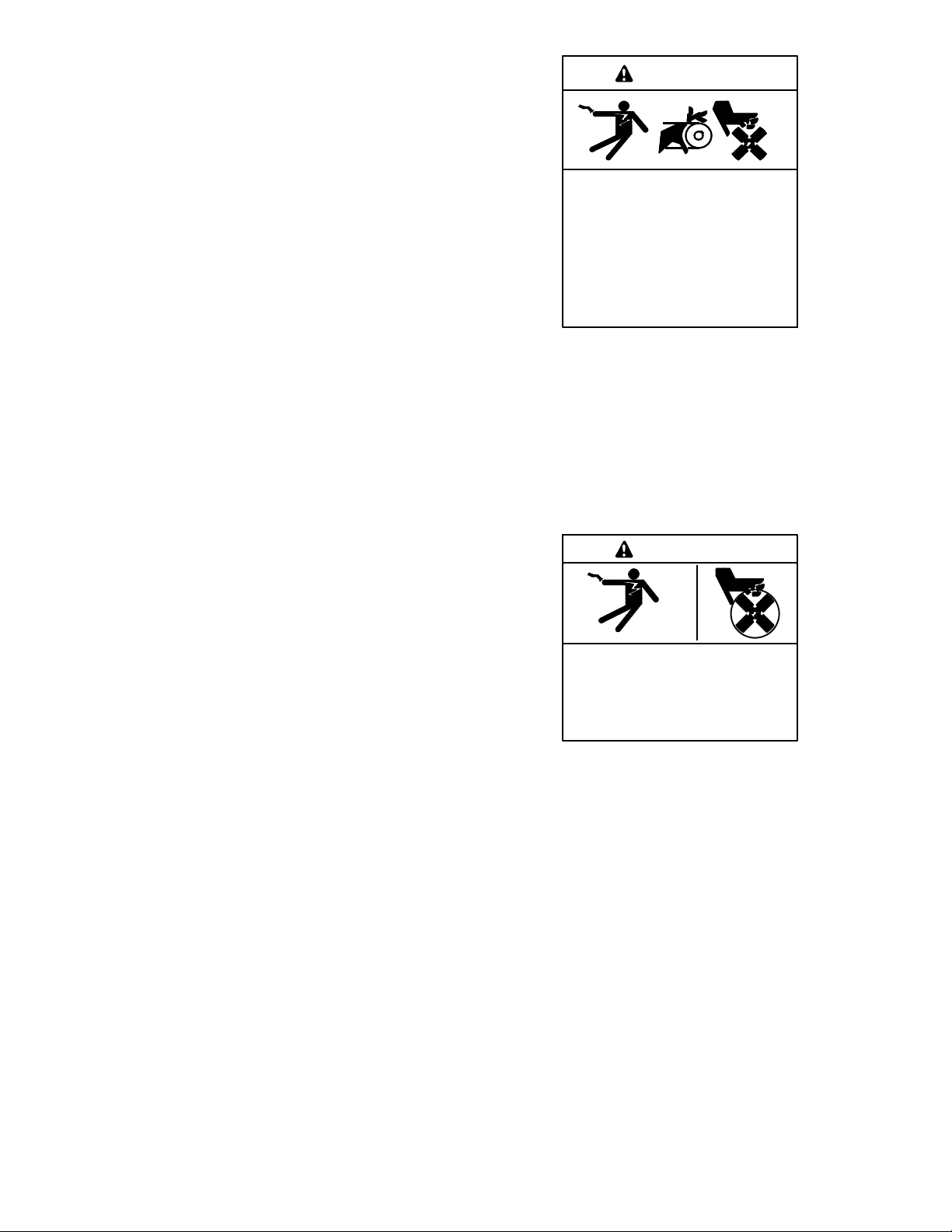

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

WARNING

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set as follows: (1) Move the generator set master

switch to the OFF position. (2) Disconnect the power to the

battery charger. (3) Remove the battery cables, negative (--)

lead first. Reconnect the negative (--) lead last when

reconnecting the battery. Follow these precautions to prevent

starting of the generator set by an automatic transfer switch,

remote start/stop switch, or engine start command from a

remote computer.

Hazardous voltage. Moving parts.

Will cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

DANGER

Grounding electrical equipment. Hazardous voltage will

cause severe injury or death. Electrocution is possible

whenever electricity is present. Ensure you comply with all

applicable codes and standards. Electrically ground the

generator set and related equipment and electrical circuits.

Turn off the main circuit breakers of all power sources before

servicing the equipment. Never contact electrical leads or

appliances when standing in water or on wet ground because

these conditions increase the risk of electrocution.

Connecting the battery and the battery charger.

Hazardous voltage will cause severe injury or death.

Reconnect the battery correctly, positive to positive and

negative to negative, to avoid electrical shock and damage to

the battery charger and battery(ies). Have a qualified

electrician install the battery(ies).