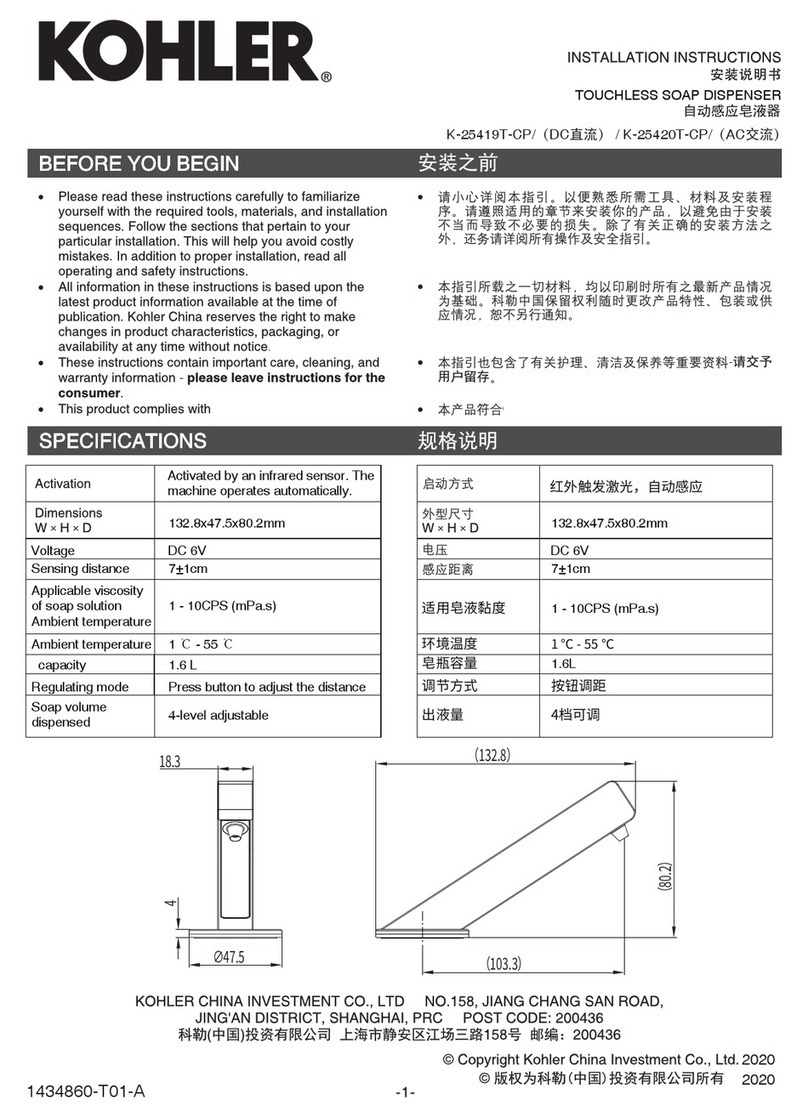

Soap Requirements

CAUTION: Risk of product damage. The foaming hand soap must have a

dynamic viscosity rating between 1 centipoise – 100 centipoise (cP) measured

in cP or grams/cm-s units. Soaps with a dynamic viscosity greater than 100 cP

can cause premature wear and damage to the soap dispenser components and

may void the product warranty.

CAUTION: Risk of property damage. Only use liquid foaming hand soap

that contains no suspended particles or microbeads. Do not use non-foaming

liquid hand soaps, which typically have a dynamic viscosity rating of 1000 cP

– 3500 cP.

CAUTION: Risk of product damage. Do not use alcohol-based soap and/or

soaps with alcohol.

NOTE: Kohler foaming hand soaps are precisely formulated to work with this

product and have a dynamic viscosity rating of 1 cP – 20 cP.

NOTE: See kohler.com for more information on recommended foaming hand soaps.

Precise information on soap material properties and dynamic viscosity rating can be

found on the soap manufacturers published material safety data sheets.

1419080-2-A4 Kohler Co.