qb701 User’s Manual

2

CONTENT

General .................................................................................................................. 4

Safety Precautions ................................................................................................ 4

Laser Safety Precautions ........................................................................................ 4

EC Declaration of conformity .................................................................................. 5

Technical Description................................................................................................ 6

Designation .......................................................................................................... 6

Misalignment Parameters ....................................................................................... 7

Specification and Features...................................................................................... 8

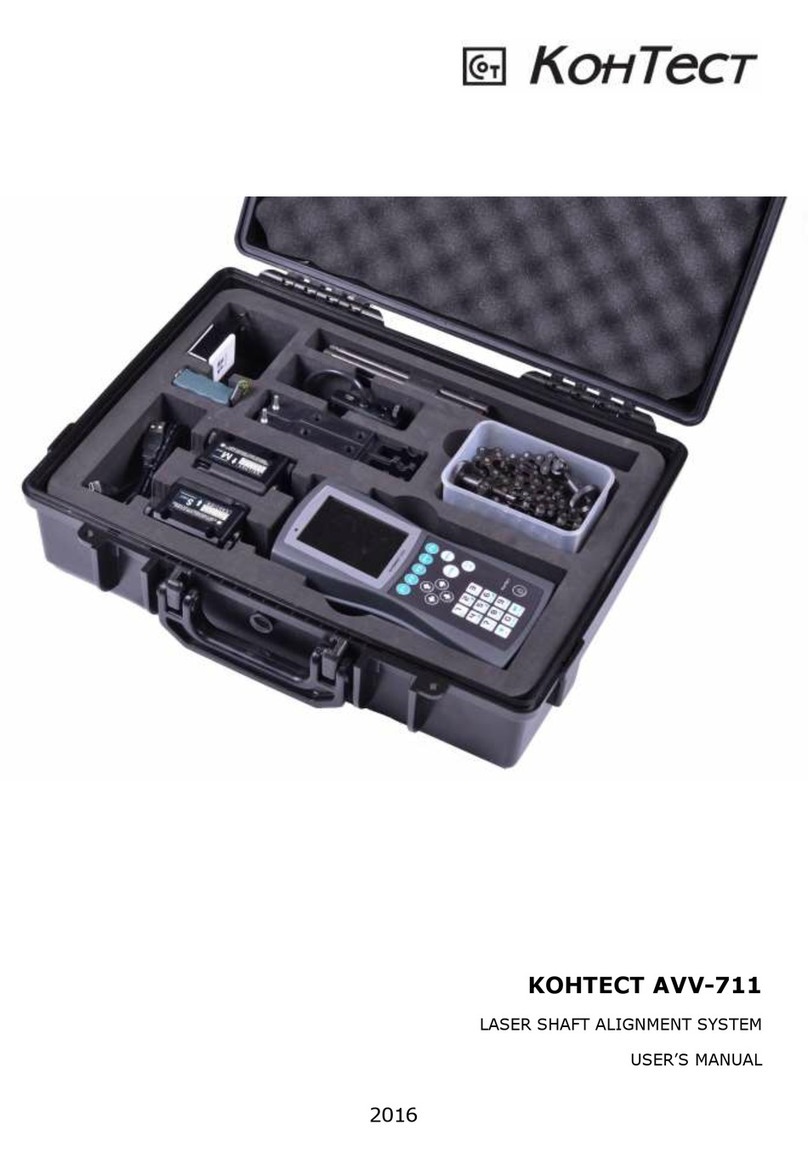

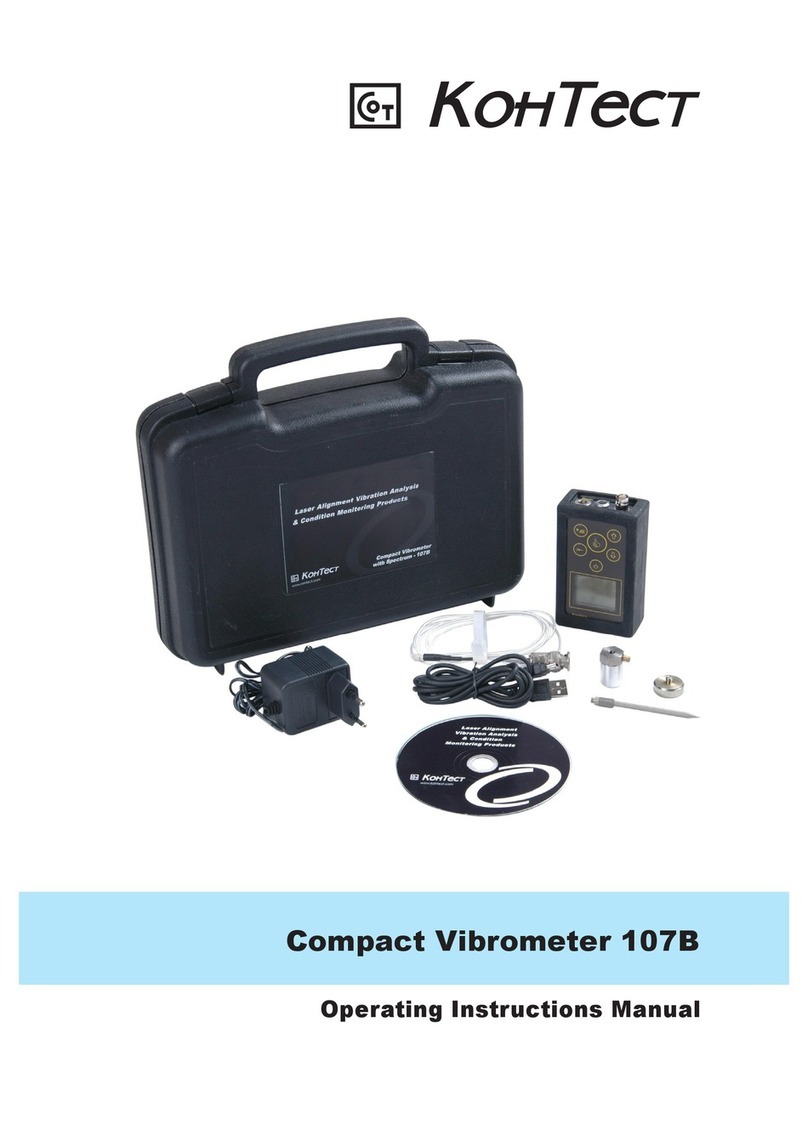

System Package.................................................................................................... 9

System overview................................................................................................... 9

Mounting Transducers.......................................................................................... 10

Laser Beam Adjustment ....................................................................................... 11

Getting Started...................................................................................................... 12

Common control keys consideration ...................................................................... 12

Auto save........................................................................................................... 12

Device setup....................................................................................................... 12

setup Menu Items ............................................................................................... 13

Horizontal Machine Alignment.................................................................................. 15

Short Explanation................................................................................................ 15

Transducer’s Positions Conventions ....................................................................... 15

Parameters......................................................................................................... 16

Tolerance Setup .................................................................................................. 17

Taking Measurements. Clock Mode ........................................................................ 18

Taking Measurements. Multipoint Mode.................................................................. 20