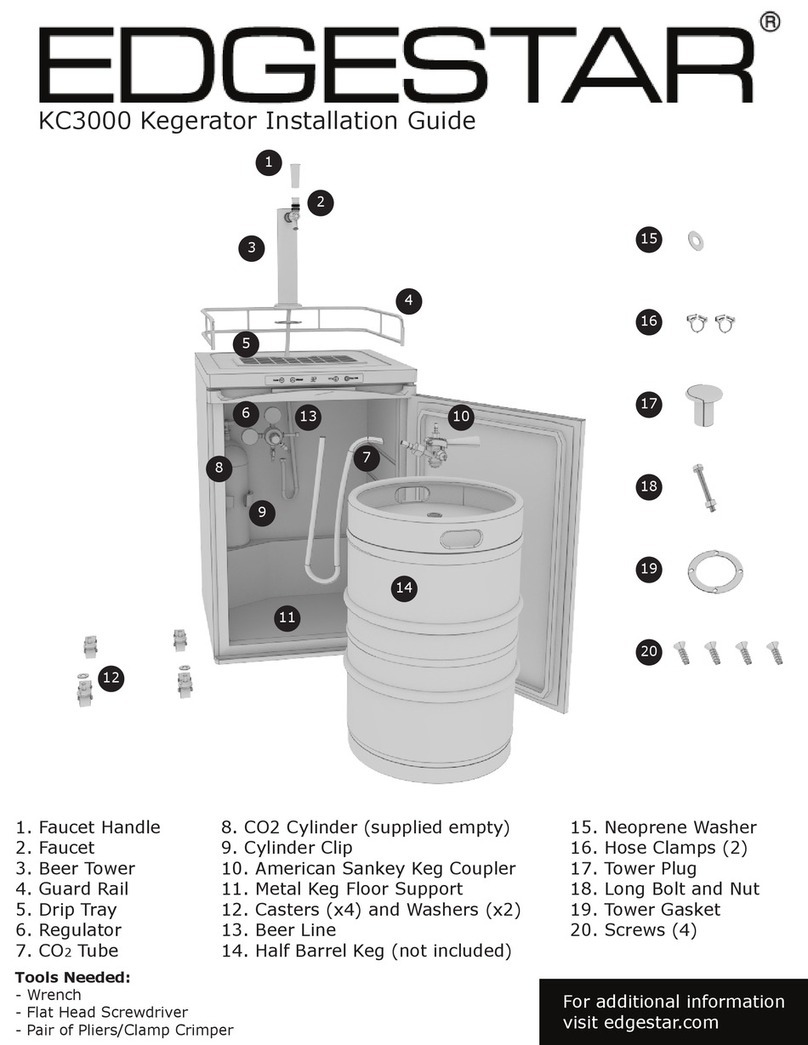

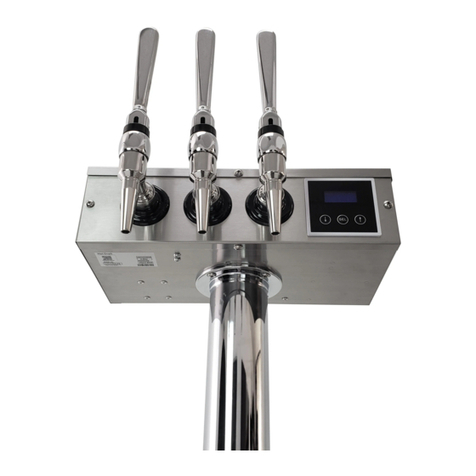

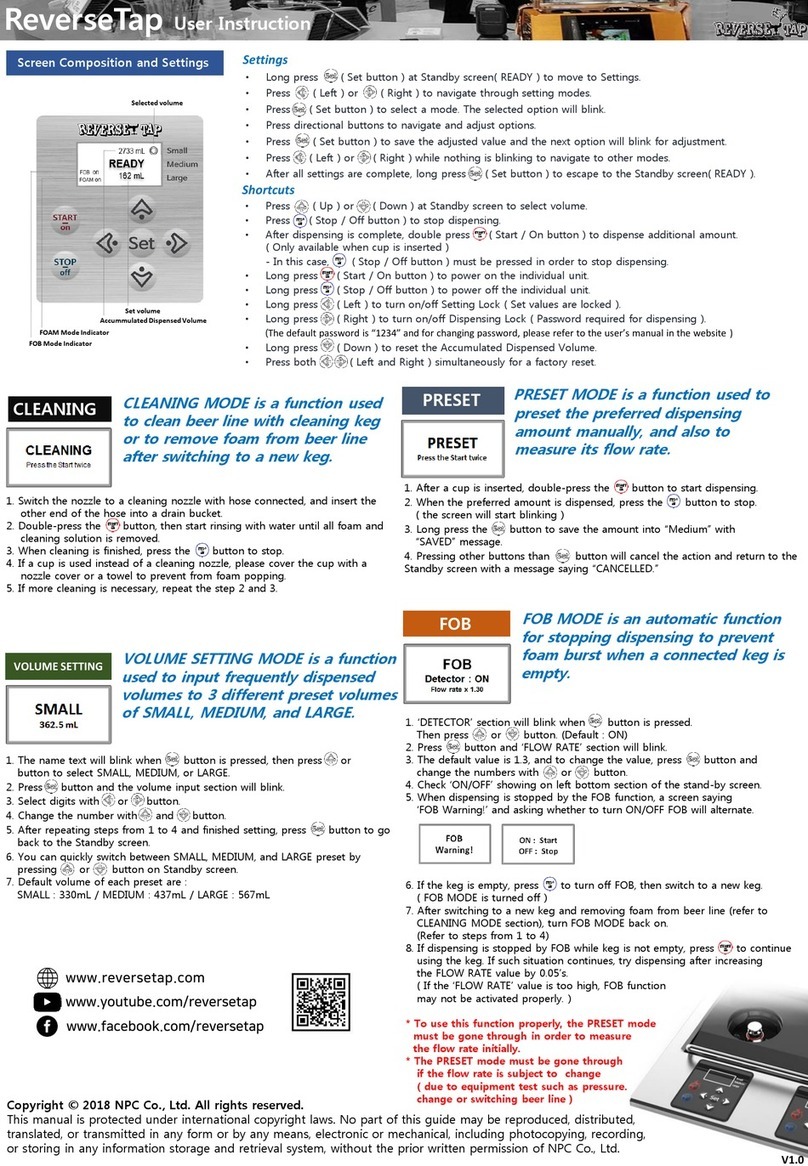

CO2Gas Tubing (larger inner diameter tubing):

The length of your gas tubing won’t aect serving the beer. Extra

gas line is included to accommodate dierent set ups. We suggest

you cut to length for your set up or roll up the extra and zip tie it.

If you have a 2 or 3 faucet tower you will need to cut your gas line

and install the Duotight tees to split the gas line.

Beer Line Tubing (smaller inner diameter tubing):

Do not cut the beer line. It is already cut to the correct length to

ensure there is enough resistance to reduce foaming.

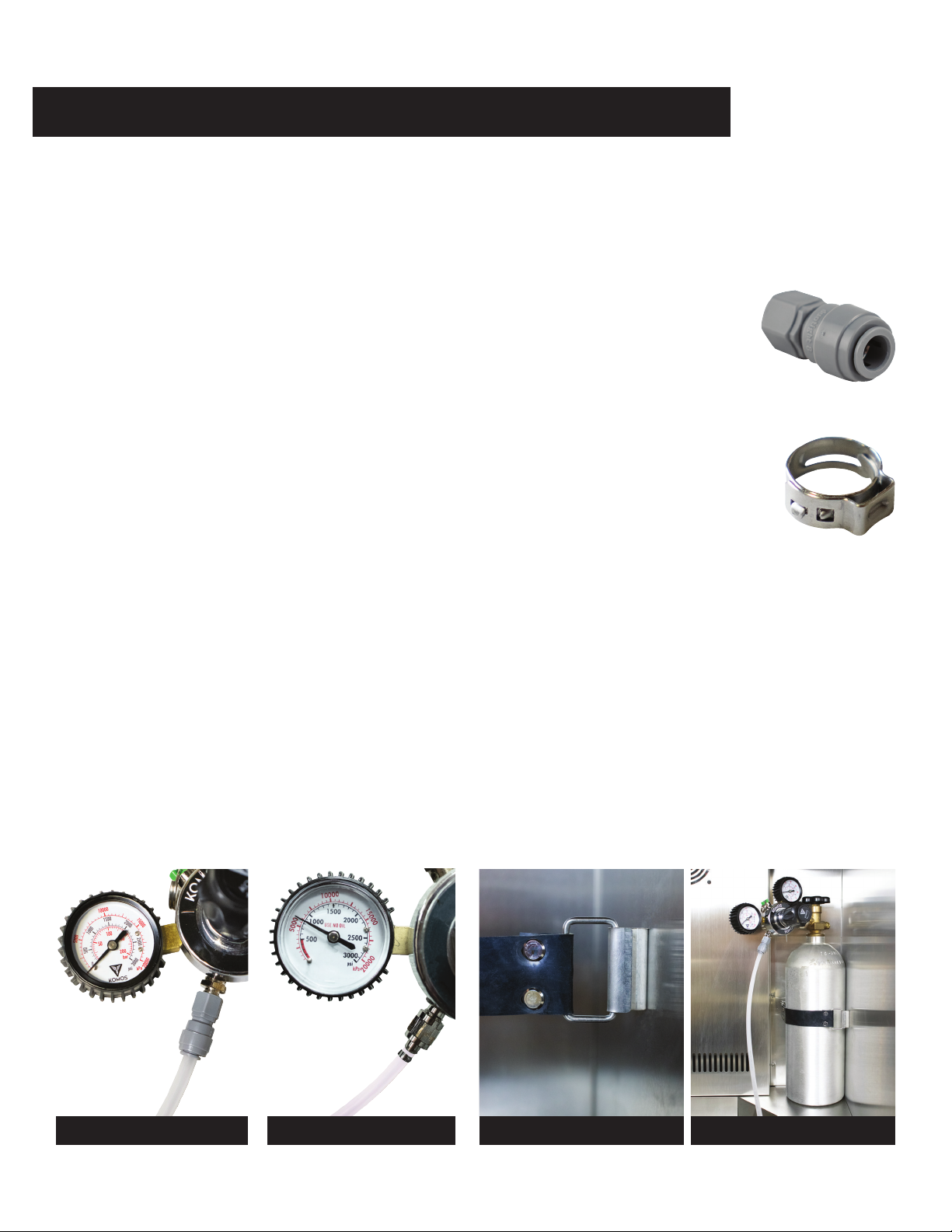

Using Duotight:

Attach the correct Duotight fittings to the keg coupler or quick

disconnects you are using. Duotight fittings should be threaded

on as tight as possible by hand and then turned an additional 180

degrees with a wrench. For pictures of additional styles of couplers

or quick disconnects see page 14.

Not Using Duotight:

If you did not purchase Duotight fittings and have couplers or quick

disconnects with traditional barbs we have included some stepless

clamps. Because the EVA Barrier tubing is an advanced two layer

tubing it is dicult to fit over barbs. Follow these steps:

1. Boil a cup of water and dip the end of tubing for 15 seconds to

soften.

2. Place stepless clamp onto tubing.

3. Insert needle-nose pliers into tubing and expand the pliers to

increase the size of the opening.

4. Push tubing onto the barb fitting and crimp the clamp securely

with pinch clamp pliers or wire cutter pliers.

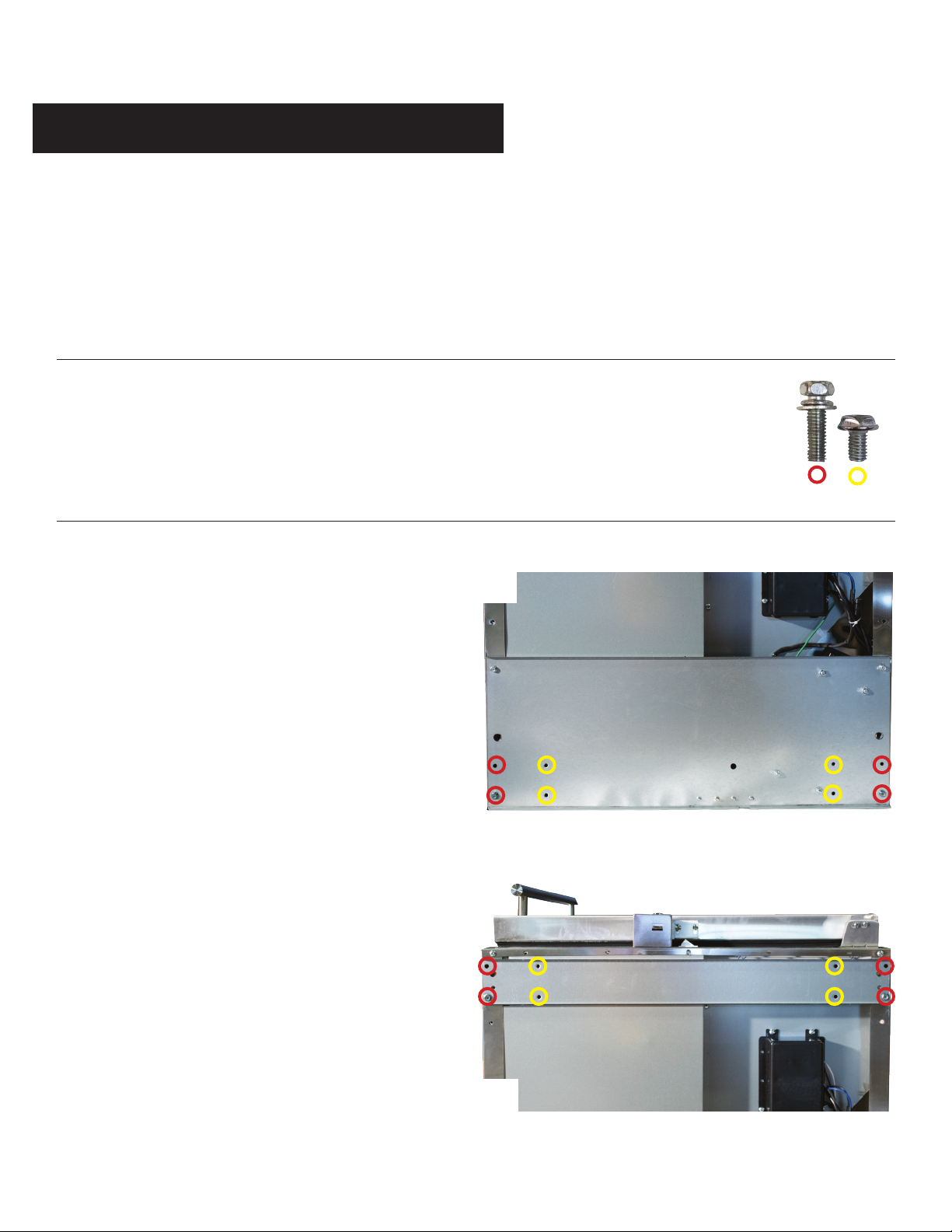

CONNECTING THE GAS TUBING & BEER LINE:

Your Komos Kegerator includes very high quality EVA Barrier tubing that is designed to work best with

Duotight connectors. Compared to standard PVC tubing, EVA Barrier is a double lined tubing that is

BPA free and greatly reduces CO2loss.

10

Duotight Gas Line Tee

GAS BEVERAGE

Gas & Beverage Quick Disconnects

With Duotight Fittings

GAS IN BEER

OUT

Commercial Tap

With Duotight Fittings