2

GB

This user manual applies to the Kongskilde CPU (Com-

ponent Pickup Unit).

The target group for this manual are operators, (electri-

cal) installers as well as maintenance and service sta.

Description:

The Component Pickup Unit system is intended as an

extension of the CVL 700 unit itself, which makes it

possible to move small components, eg. from a con-

tainer in a warehouse and into a production line, in ap-

portioned quantities.

The CPU is designed to handle components ranging in

size from 10 to 50 mm in cross section, provided they

do not have a geometry that allows them to interlock, or

are particularly fragile. The CVL cannot handle liquids

or adhesive / damp components.

It is possible to control the performance of the con-

nected blower based on the current suction needs of

the CPU, by retrotting a MUC control - see section

"Accessories".

The system moves the components by evacating them

through a pipe / hose system. The pipe system consists

of steel pipes and exible hoses, with a diameter of

Ø100 mm.

The Component Pickup Unit system must not be used

in the food and pharmaceutical industry or in areas

where the ATEX directive is required.

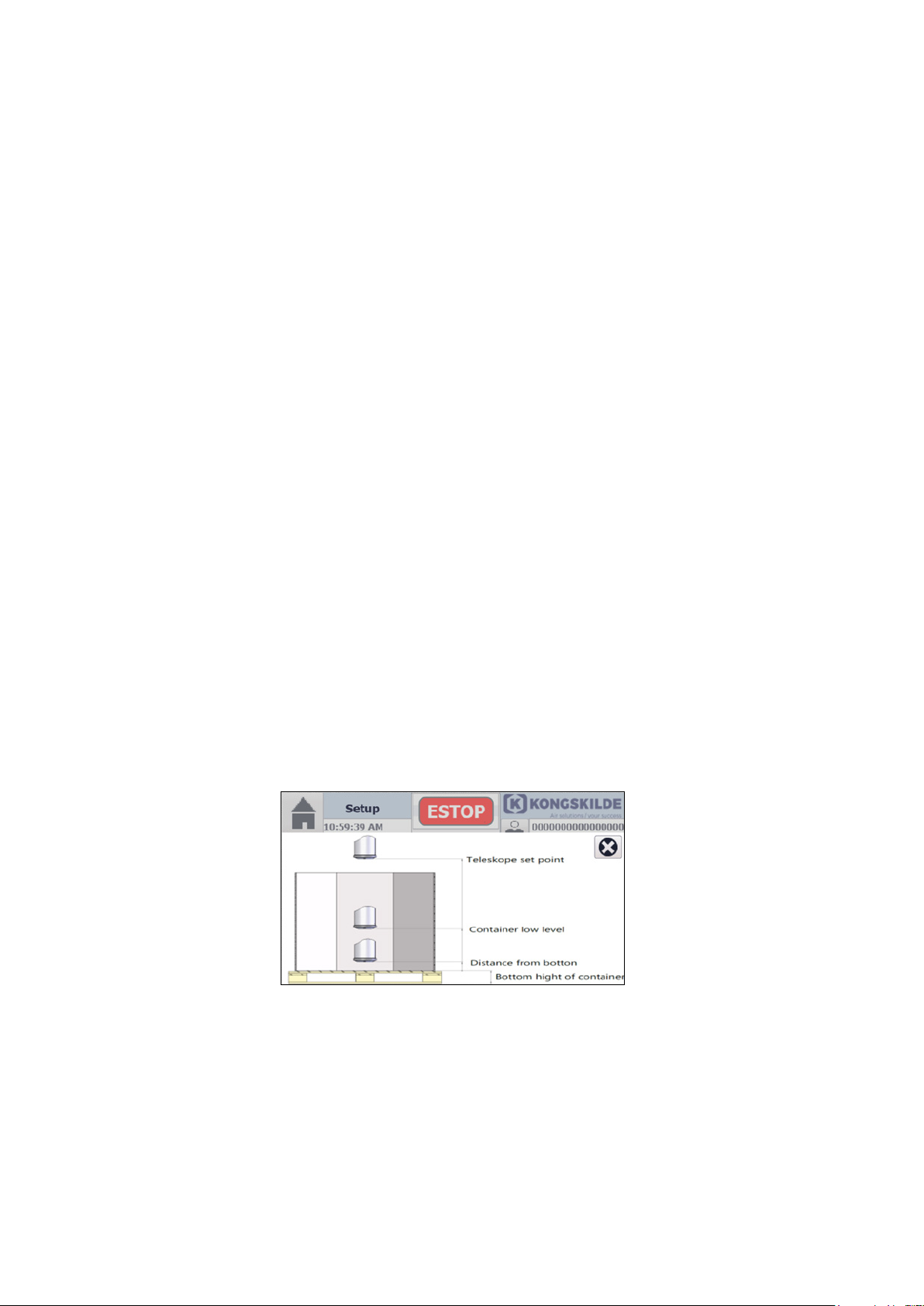

The container containing the components to be moved

is emptied via a telescopic suction pipe which evacu-

ates the components up and through the suction string.

The telescopic suction pipe moves slowly through the

container, while swinging to the sides and back and

forth, removing layer after layer of components.

The container must measure a maximum of 1,2 x 1,2 x

1,8m. The container must not contain loose parts such

as cardboard discs or plastic foil that can be sucked to

the telescopic tube.

The air velocity in the suction string is measured and

regulated by regulation throttle EAR100-C. It is impor-

tant that the air velocity is kept constant and as low as

possible, to ensure that the components are not dam-

aged during transport.

The air velocity sucient to transport the components

of the piping system, is not large enough to absorb the

components from the container and into the telescopic

suction pipe. Therefore, the air velocity locally at the

"pickup" end of the suction pipe is increased. Boost air

velocity is measured and regulated by regulation throt-

tle EAR100-B.

The components are evacuated into the CVL via the

telescopic pipe and associated piping. At the top of the

CVL there is an ultrasonic sensor that detects when the

CVL is full of components (about 10 liters of compo-

nents), in combination wit the suction time setting in the

control unit. Then the top valve stops suction in the pipe

string, where after the bottom valve in the CVL opens

and empties the components. Top valve and bottom

valve in the CVL are driven by their own air cylinder.

When the CVL is full and the air ow stops in the pipe

system, the telescopic suction pipe must be raised a

distance corresponding to the component height, to en-

sure that the components in the vertical part of the suc-

tion pipe fall out and do not block the suction pipe. After

the airow has restarted, the telescopic suction pipe is

lowered back to its original position and continues to

remove layer after layer of components.

The control of the CPU is connected to the control of

the CVL, to the control of the control valves (EAR 100),

and to the blower control. The system is integrated and

controlled from the CPU's control.

Access to the CPU control setting is done through the

operator panel in the column. The operator panel can

be logged in either as Operator or Tech, and only Tech

has rights to change settings.

See possibly section "Startup" with associated dia-

grams in the CVL manual, which describes the follow-

ing 3 installation modes:

Diagram C (Continuous process) - Should compo-

nents be drawn, typically from a magazine, with dis-

charge when a preset level in the CVL is reached, this

mode of operation is used. After discharge, the process

is repeated. This operating mode can be equipped with

start / stop contact, whereby the CVL can be stopped

when eg. the magazine is emptied.

Diagram D (Transport to external container with

level sensor) - Should components be drawn, typi-

cally from a magazine, with discharge in a container

equipped with full- and empty sensor, this operating

mode is used. The full- and empty sensor controls the

CVL, and ensures, that there are always components

in the container. This operating mode can be equipped

with start / stop contact at the CPU, whereby the CVL

can be stopped when eg. the magazine is empty.

It is optional if the blower should be started and

stopped by the control, or run constantly. If case the

blower should be controlled by the CVL control, the

blower must be connected, see diagram D.