4SERVICE MANUAL

SPECIFICATIONS

Model name : SRX-101A

Film transport method : Continuous roller transport.

Film type and sizes : Sheet film, 10 x 10 cm~ 35 x 43 cm(14 x 17 inch) sizes.

Processing capacity :

Process cycle switching : Available by a service engineer.

Processing solution volumes : DEV tank : 3.9 liters(1.03 gallons)

FIX tank : 1.8 liters(0.47 gallons)

WASH tank : 1.4 liters(0.37 gallons)

Temperature control : Processing solution temperature;

Controlled by the temperature control tank, with the thermistor monitoring,

and with the heater heating.

Drying temperature;

Controlled automatically according to a fixed temperature setting.

Replenishing system : Replenishing volume for the film sheet is calculated exchanging with

24 x 30 cm or 10 x12 inch film

Circulation system : Continuous pumping of developer and fixer solutions.

Wash water : Ordinary tap water 5 ~ 30:(41 ~ 86<)

Water pressure 29.4 ~ 784 kPa(0.3 ~ 8kgf/cm

2

, 98 ~ 112psi)

Water supply : 0.8 liters(0.22 gallons)/min.

Standby functions : 10min./30min./Continuous operation. (Selectable by a service engineer)

Power source : AC 115/120V, single phase, 12A, 60 Hz.

AC 200/230/240V, single phase, 6A, 50Hz.

Dimensions(W x D x H) : 610 x 680(900 incl. feed table) x 453 mm

24.0 x 26.8(35.4 incl. feed table) x 17.8 inch.

Weight : CE 40kg (47kg with processing tank full)

UL 37kg (44kg with processing tank full)

81 lb (97 lb with processing tank full)

Certification : Conforms to UL, FDA, TÜV

Applied standard : FCC/CE

Heat generation : Approx.3135kJ/hr max.

Noise level : Approx.55dB(A) max.

Operating condition : 15 ~ 30:(59 ~ 86<), 30 ~ 75%RH(no condensation)

Storage and transport condition : -20 ~ 60:(--4 ~ 140<), 20 ~ 95%RH(no condensation)

Accessories : Measuring cup, Funnel, Installation parts kit, Replacement parts kit,

Replenisher tanks, and Operation manual.

Optional equipment : Light shield panel, Stand, Splash guard,

DEV Temp. Control kit.(CE only)

Remarks for CE Version : This equipment is the CE marking product conformable to the directive

93/42/EEC (MDD) and the harmonized standard EN60601-1, EN60601-1-2.

Medical film processor SRX-101A is produced in factories that have been

certified to be in compliance with the ISO13485:2001, IS09001:2000 quality

control standards.

Remarks for UL Version : Medical film processor SRX-101A is produced in factories that have been

certified to be in compliance with the IS09001 : 2000, and IS013485 : 2001

quality control standards, as well as with the medical device directive FDA

Premarket Notification 510(k) and GMP.

*The above specifications are subject to change without prior notice.

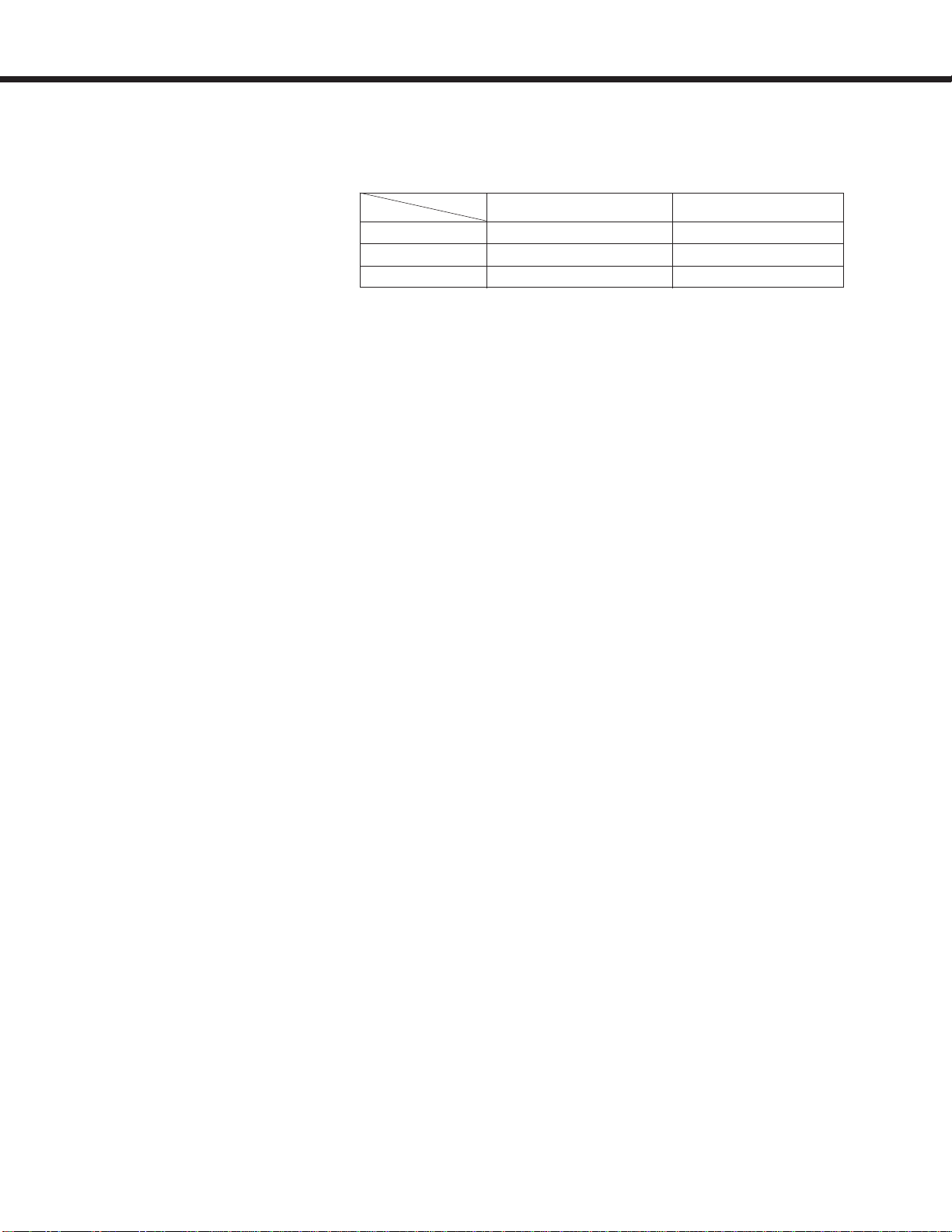

Size

Cycle

24 x 30 cm or 10 x 12 inch 35 x 43 cm(14 x 17 inch)

90sec. 75 60

120sec. 70 55

180sec. 55 40

(sheets/hr)

1. Specifications