Konica Minolta Copier 2223 User manual

Other Konica Minolta Printer manuals

Konica Minolta

Konica Minolta BIZHUB 500 User manual

Konica Minolta

Konica Minolta Magicolor 5430 DL User manual

Konica Minolta

Konica Minolta bizhub 552 Manual

Konica Minolta

Konica Minolta magicolor 5670EN Original instructions

Konica Minolta

Konica Minolta BIZHUB 226 User manual

Konica Minolta

Konica Minolta AccurioPress 6136 User manual

Konica Minolta

Konica Minolta Network Printer User manual

Konica Minolta

Konica Minolta bizhub C10P User manual

Konica Minolta

Konica Minolta BIZHUB 500 User manual

Konica Minolta

Konica Minolta bizhub press c1060 User manual

Konica Minolta

Konica Minolta bizhub 40p User manual

Konica Minolta

Konica Minolta bizhub 4700P User manual

Konica Minolta

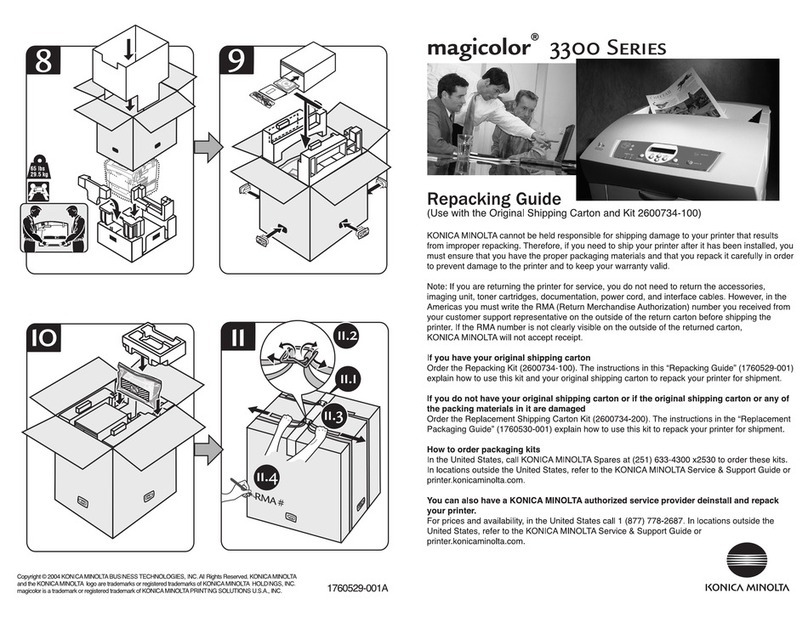

Konica Minolta Magicolor 3300 Manual

Konica Minolta

Konica Minolta PAGEPRO 5650EN User manual

Konica Minolta

Konica Minolta bizhub PRO 1200 Series Manual

Konica Minolta

Konica Minolta DRYPRO Model 793 User manual

Konica Minolta

Konica Minolta KM256 User manual

Konica Minolta

Konica Minolta bizhub PRO 950 Series User manual

Konica Minolta

Konica Minolta bizhub PRO 951 Installation manual

Konica Minolta

Konica Minolta Di1610 User manual