KONRAD 600B SERIES INSTALLATION GUIDE JANUARY 2019 - V4.0PAGE 6

Stern Drive

General Information

The Konrad 600B Series stern drives are

designed to accommodate engines that generate

up to 1200 Nm (885 lb. ft.) of torque at maximum

rated RPM. Maximum torque ratings are drive

model and application dependent.

There is a sixteen degree (16°) trim range to

optimize vessel performance while underway.

To achieve optimal wear it is recommended that

the stern drive be operated between the +20to -20

degree trim range while under power.

There is an additional 30 degrees (30°) of lift

range that may only be used in an emergency or

when the stern drive is being serviced or transported.

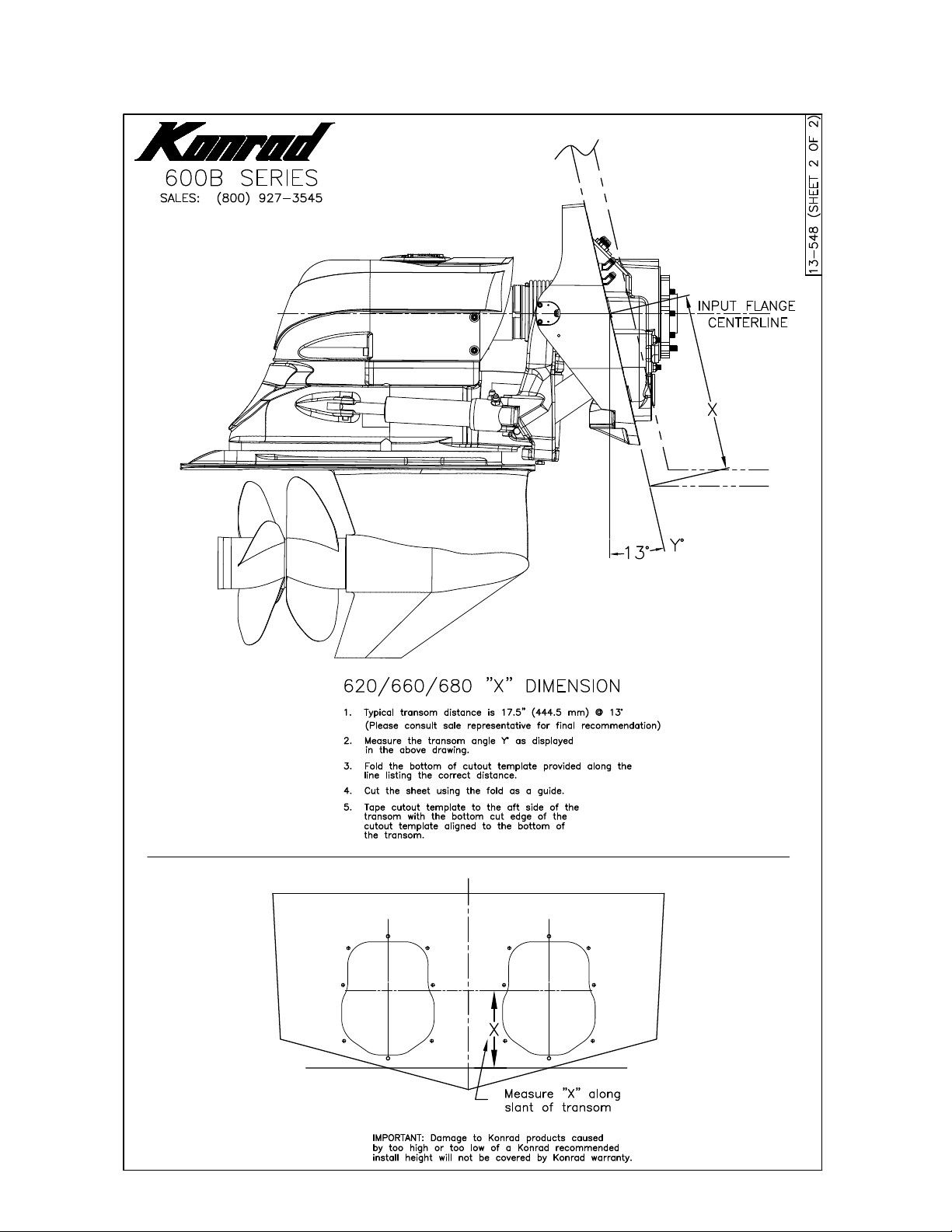

The Konrad 600B Series stern drives are

designed for applications where the vessel transom

angle is 13 degrees (13°). Applications that do not

meet this criteria may require extra equipment or

modications, or may not be possible at all. The

Konrad 620B and 680B stern drives are designed

to accommodate propellers (aluminum and

stainless steel) with a maximum diameter of 20 in.

(50.8 cm). The Konrad 660B can accommodate

propellers (aluminum and stainless steel) with a

maximum diameter of 16 in. (40.6 cm).

General Operation

The engine produces power (clockwise or

counterclockwise) that is transmitted through a re-

versing transmission. A coaxial planetary-style re-

versing transmission is normally used. The trans-

mission is connected to the stern drive via close

couple or drive shaft. The power is then transmit-

ted through a series of shafts and gears to the pro-

peller(s).

Safety Notices

Read and understand all of the safety precau-

tions and warnings before performing any installa-

tion or repair.

This list contains the general safety precautions

and warnings that MUST be followed to provide

personal safety. This list is only a suggested safe-

ty guideline. Working conditions vary greatly and

safety measures will vary upon your individual cir-

cumstances.

ALWAYS USE CAUTION. Make sure the

work area surrounding the product is safe. Be

aware of hazardous conditions that can exist.

ALWAYS wear protective eyewear and

protective footwear when working.

DO NOT wear loose-tting or torn clothing.

Remove all jewelry when working.

DO NOT work on anything that is support-

ed only by lifting jacks or a hoist.

ALWAYS use blocks or proper stands to

support the product before performing any

service work.

TO AVOID PERSONAL INJURY, use

a hoist or get assistance when lifting stern

drive components. Make sure all lifting de-

vices such as chains, hooks or slings are in

good condition and are of the correct lifting

capacity.