CONTENTS

3

www.krohne.com08/2020 - 4007792902 - MA SHD 200 R02 en

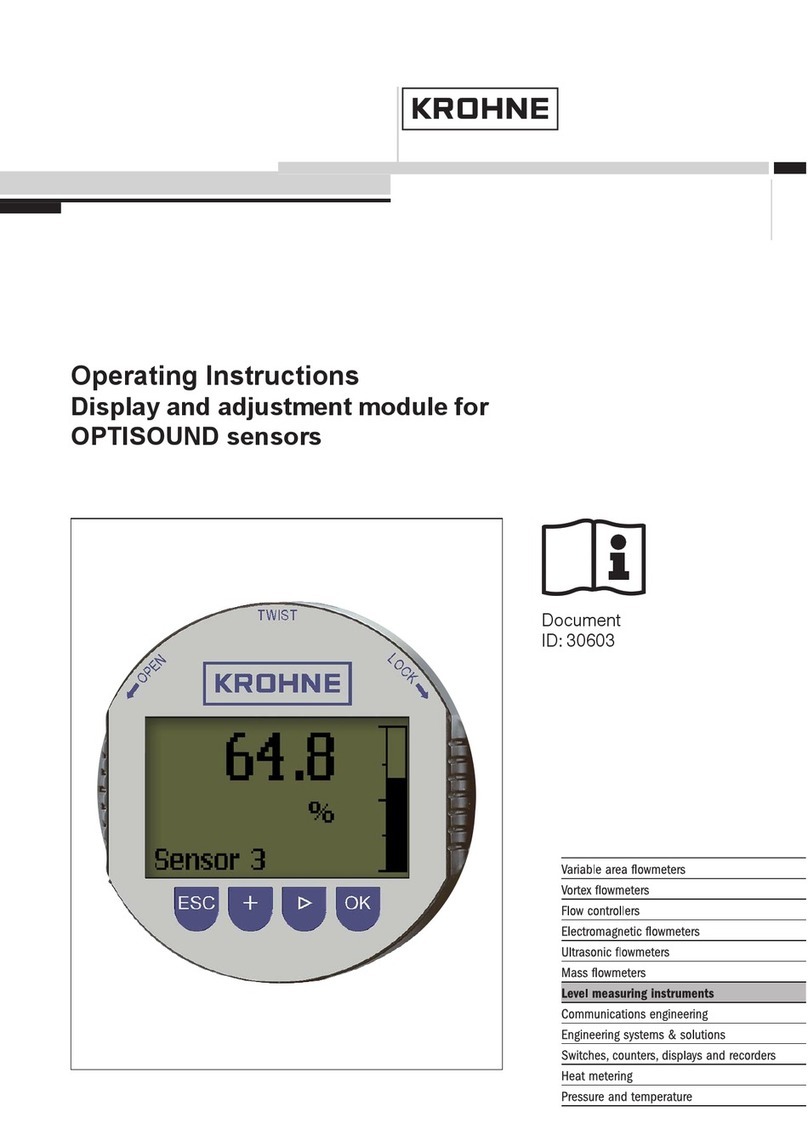

SHD 200

1 Safety instructions 5

1.1 Certifications .................................................................................................................... 5

1.2 Software history ............................................................................................................... 5

1.3 Intended use ..................................................................................................................... 6

1.4 Safety instructions from the manufacturer ..................................................................... 6

1.4.1 Copyright and data protection ................................................................................................ 6

1.4.2 Disclaimer ............................................................................................................................... 7

1.4.3 Product liability and warranty ................................................................................................ 7

1.4.4 Information concerning the documentation........................................................................... 7

1.4.5 Warnings and symbols used................................................................................................... 8

1.5 Safety instructions for the operator................................................................................. 8

2 Device description 9

2.1 Scope of delivery............................................................................................................... 9

2.2 Device description .......................................................................................................... 10

2.3 Nameplate ...................................................................................................................... 11

3 Installation 12

3.1 General notes on installation ......................................................................................... 12

3.2 Storage and transport .................................................................................................... 12

3.3 Point-to-Point connection - analogue / digital mode .................................................... 13

3.4 Pre-installation requirements ....................................................................................... 14

3.5 Opening the housing....................................................................................................... 15

3.6 Wall mounting ................................................................................................................ 16

3.6.1 Housing ................................................................................................................................. 16

4 Electrical connections 17

4.1 Safety instructions.......................................................................................................... 17

4.2 Important device-specific notes on electrical connection............................................. 17

4.3 Connection diagram overview ........................................................................................ 18

4.4 Connecting the field device cable .................................................................................. 19

4.5 Connecting the second current output .......................................................................... 20

4.6 Connecting the relay outputs ......................................................................................... 21

4.7 Connecting the external HART adapter ......................................................................... 22

4.8 Power supply .................................................................................................................. 22

5 Start-up 24

5.1 Start-up........................................................................................................................... 24

6 Operation 26

6.1 Operating elements........................................................................................................ 26

6.2 Function tables ............................................................................................................... 27