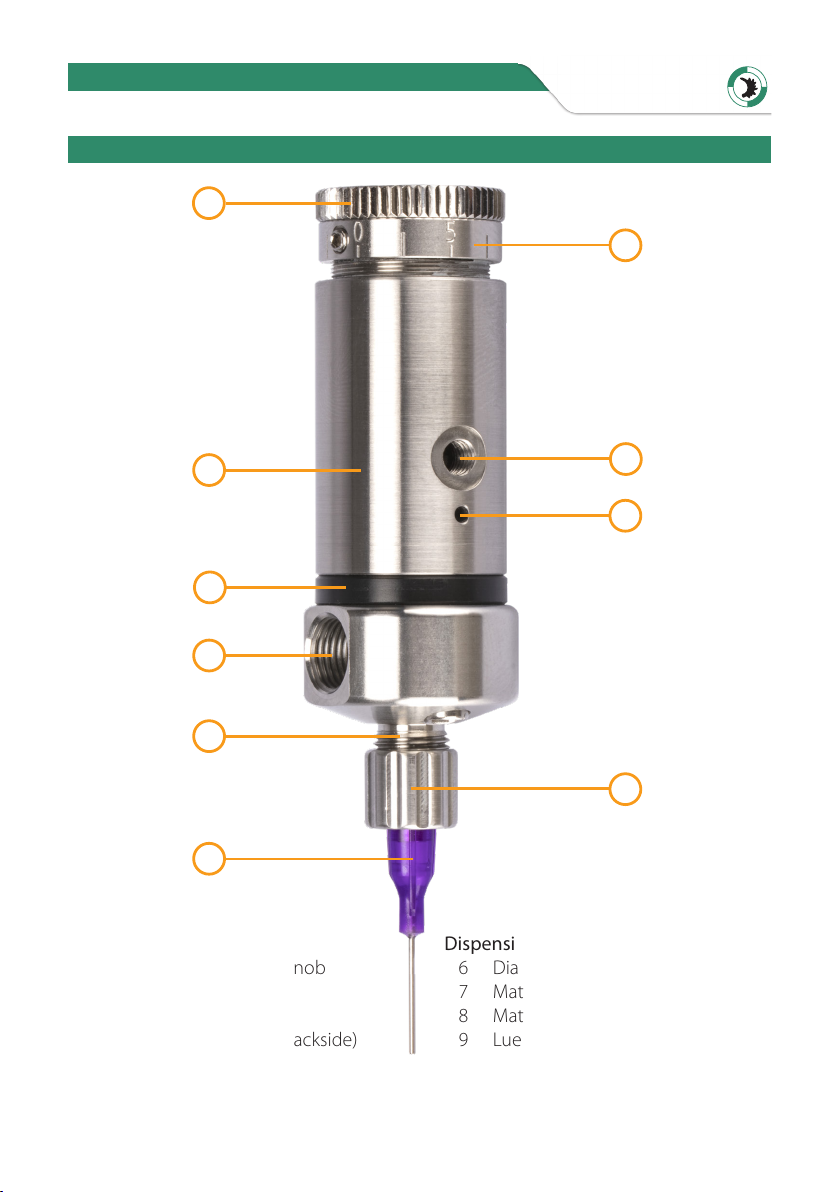

Bedienungsanleitung Membranventil DV-5625-U / -SS

Manual diaphragm valve DV-5625 Series

Note:

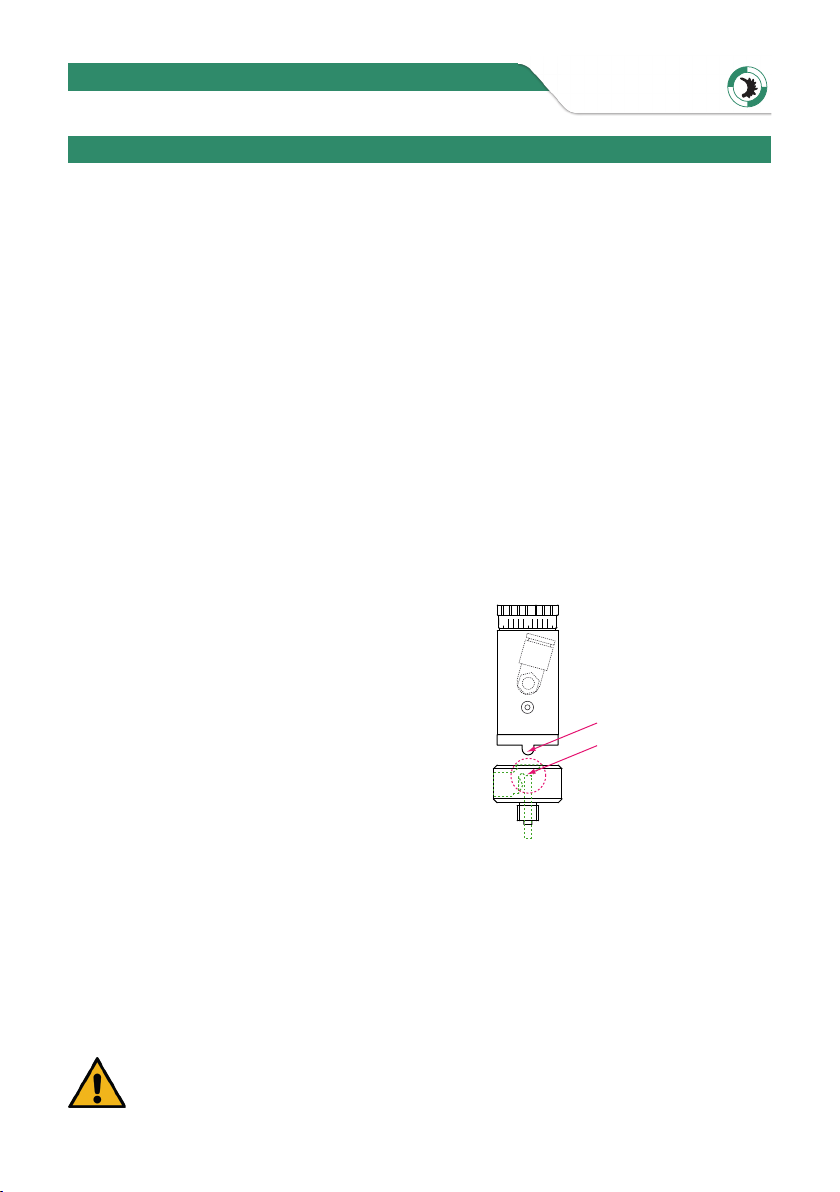

Do not turn the fitting too deeply into the valve.

4. Place a suitable dispensing tip on the material outlet and fix it with the union nut.

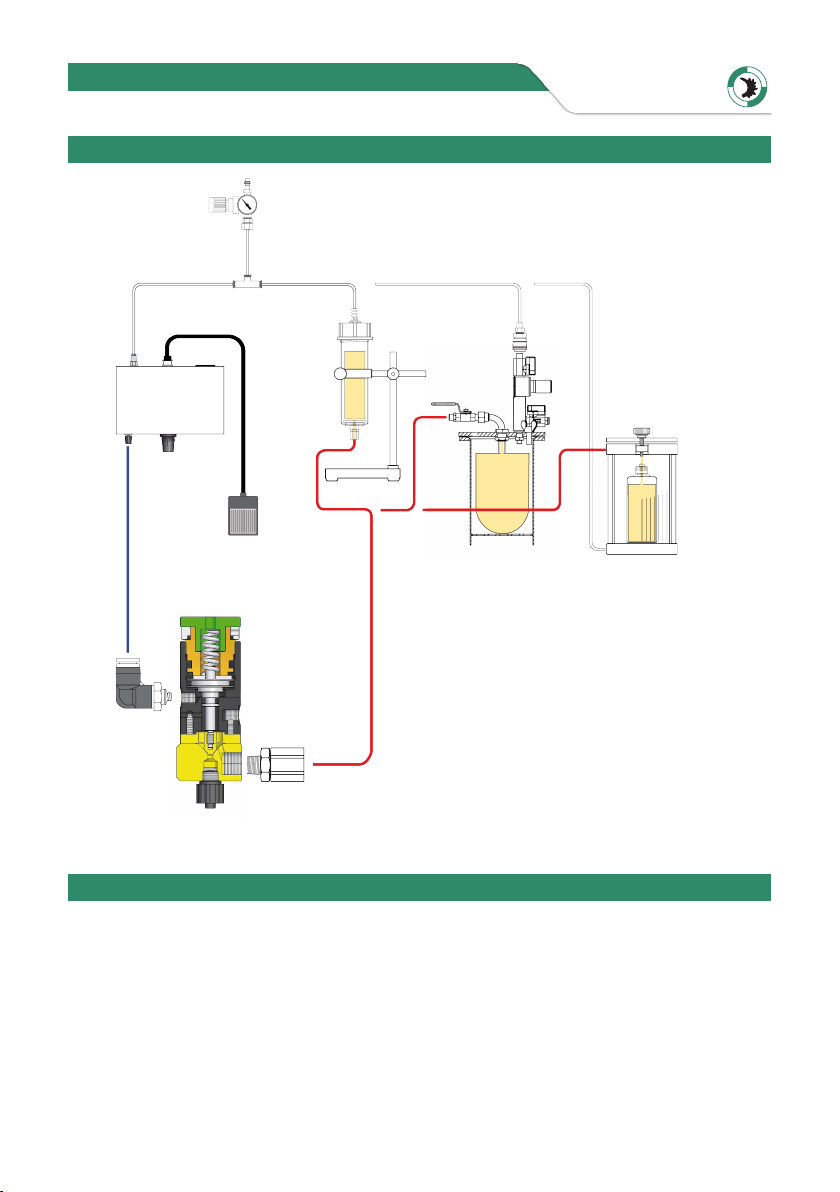

5. Set the material pressure as follows (but max. 5.0 bar). Set the material pressure to

max. 0.5 bar if you want to dispense very thin material (such as water or solvents).

Set the material pressure for highly viscous material to approx. 2.0 bar and adjust it

according to the required dispensing.

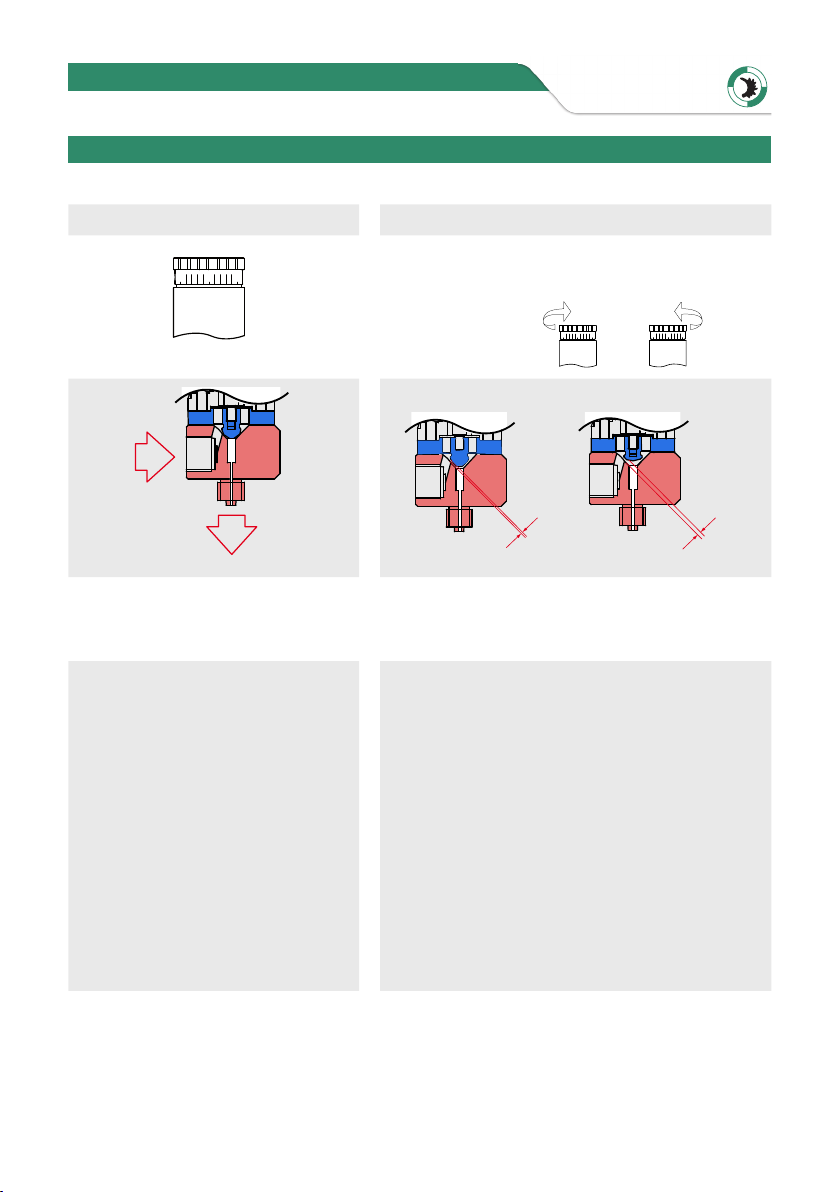

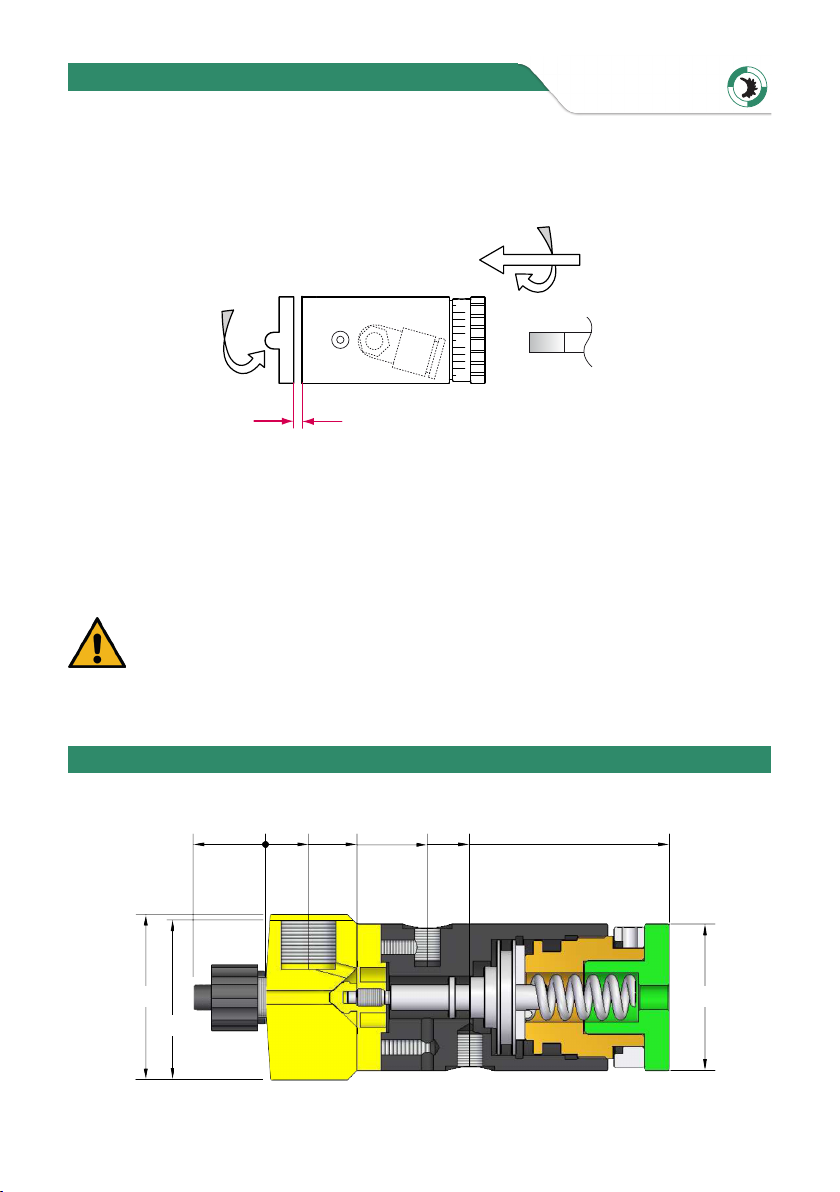

6. On delivery, the adjusting screw is set to position 3 (center of full stroke).

Increase or decrease the setting as required. The maximum stroke is 0.6 mm.

This corresponds to a complete turn of the set screw.

Note:

If you turn the adjusting screw 2 turns or more often counterclockwise, the

return spring loses its effect and the valve opens continuously. This causes

the material to be dispensed continuously, even if no control pressure is

applied.

7. Adjust the valve, material pressure, and controller settings so that material slowly

exits the valve.

(This prevents bubbles from forming in the dispensing material during dispensing.)

8. Select the operating mode„Timer“ or„Manual“ on the controller depending on the

desired dispensing.

9. You can influence the dispensing result using the following 4 options:

Increase or decrease material

pressure

Pressure increase leads to increase

of dispensing quantity

Pressure reduction leads to a reduction

of the dispensing quantity

Diameter of dosing tip Thin dispensing tip reduces the dispensing quantity

Thick dispensing tip increases the dispensing quantity

Adjusting screw for

stroke adjustment

Large stroke setting increases the dispensing quantity

Low stroke setting reduces the dispensing quantity

Dispensing time

Long dosing time increases the dispensing quantity

Short dosing time reduces the dispensing quantity

8