PROFIBUS PA 2

5

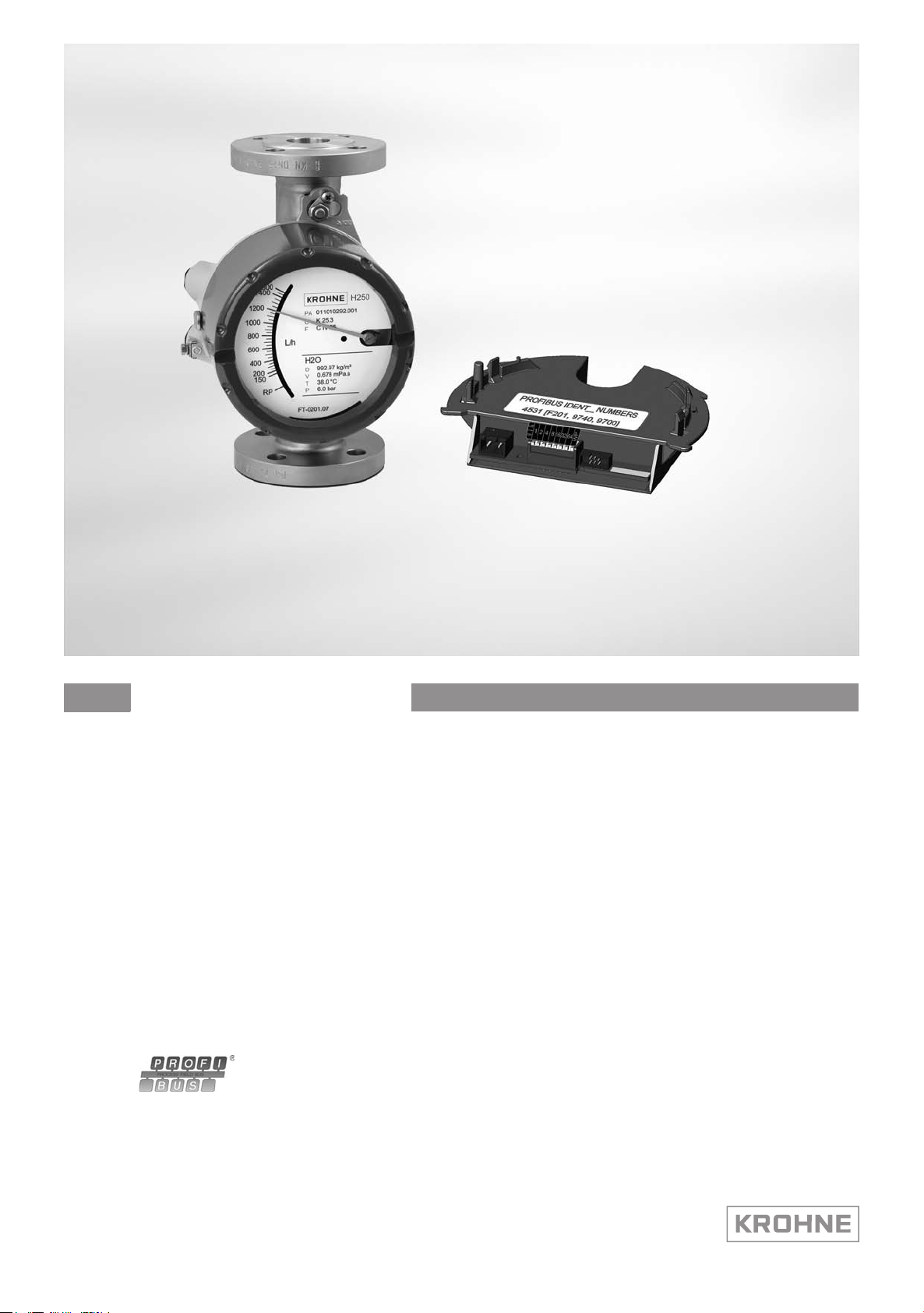

H250 M40 ESK4

www.krohne.com03/2014 - 4002251801 - AD H250/M40 PROFIBUS R01 en

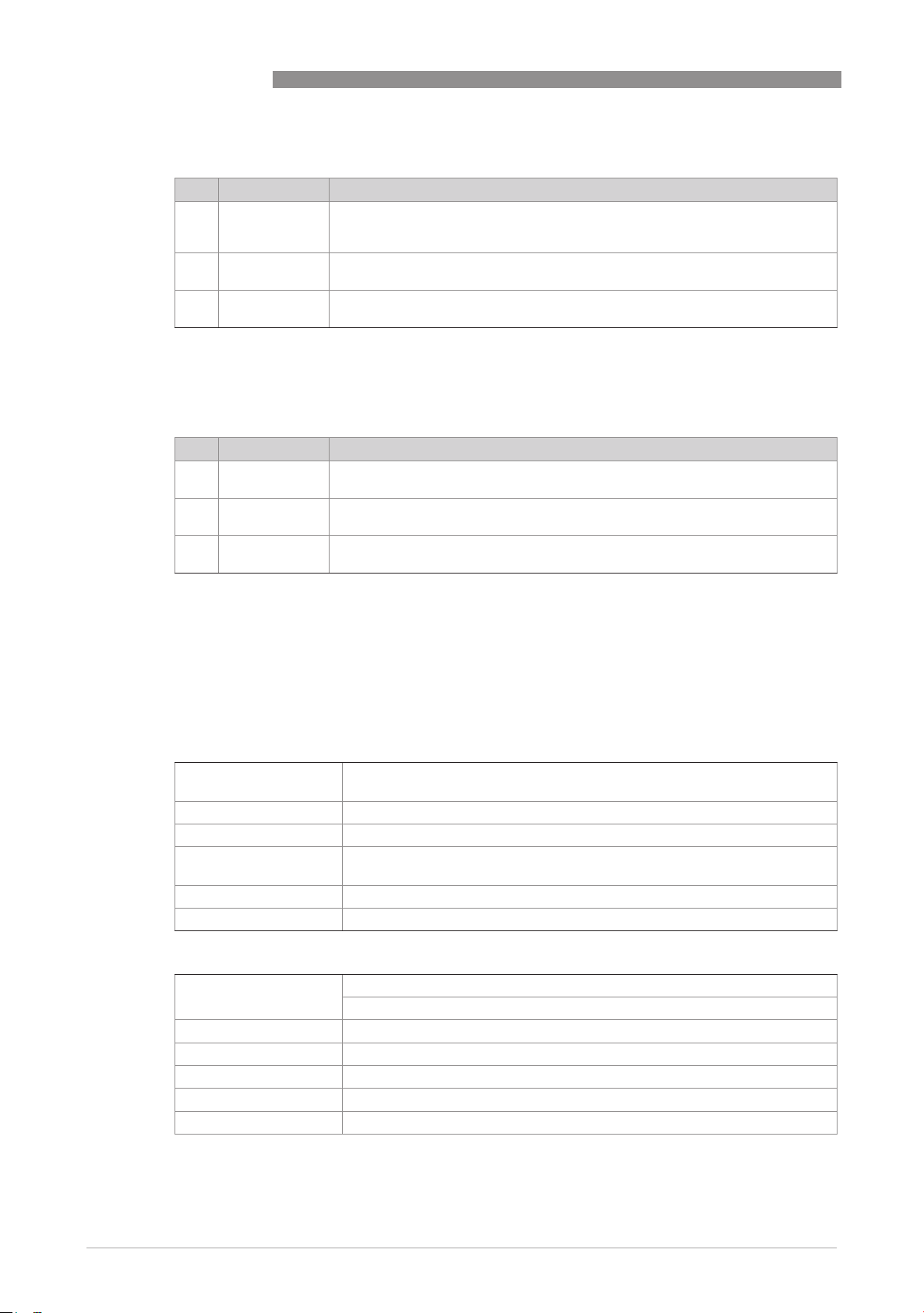

2.3 PROFIBUS PA Profile implementation

The PROFIBUS PA Profile 3.02 defines standardized parameters and functions for PROFIBUS

devices used for process control. It describes a PROFIBUS device as a function block application,

i.e. parameters and functions are grouped into different blocks. In the ESK4-PA transmitter the

following blocks are implemented:

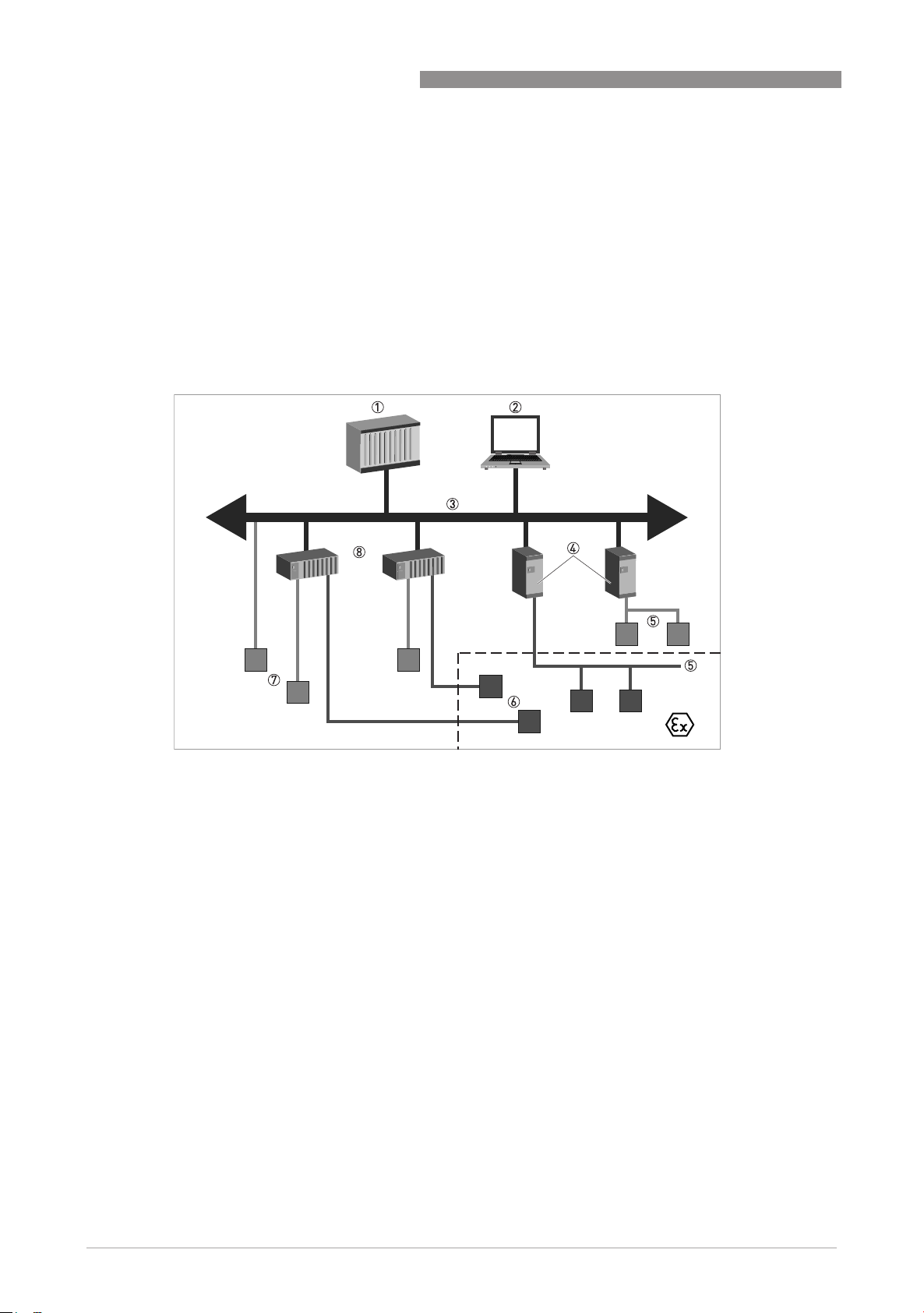

The Analog Input Function Block and the Totalizer Function Blocks provide the data interface

towards a process control system (e.g. a PLC); i.e. their input/output data can be read/written by

the control system. In a PROFIBUS network this is done via cyclic communication services.

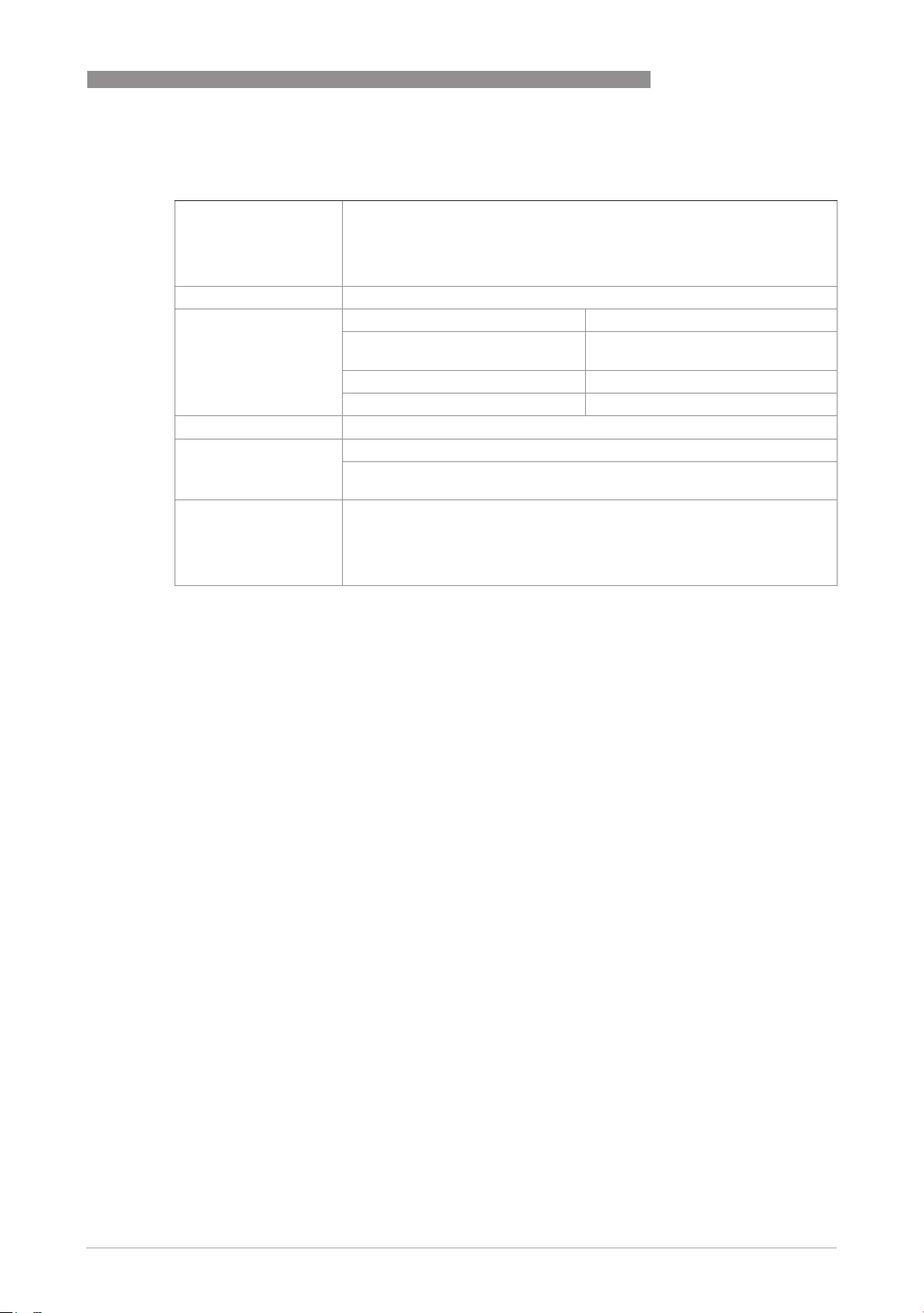

From the PROFIBUS point of view the ESK4-PA transmitter is designed as a modular device with

three slots. While the Analog Input Function Block is assigned (as virtual module) to slot 1 the

Totalizer Function Blocks are assigned (as virtual modules) to slot 2 and 3. This assignment is

fixed and cannot be modified by the user. Nevertheless the measuring data for each Function

Block is selectable according to the following tables:

Device calibrated for Volume Flow

The calibration units are used as default units.

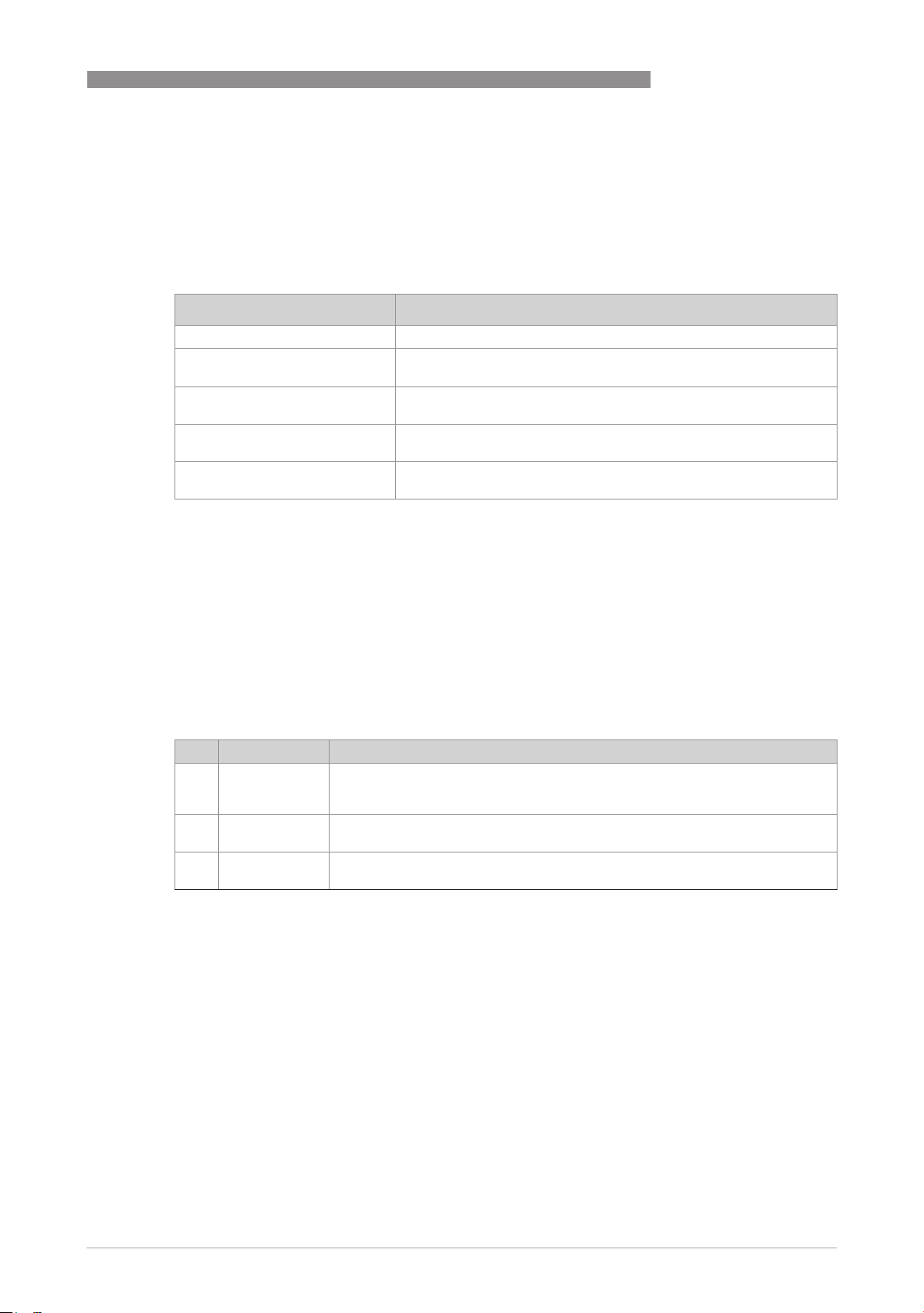

Block Usage

1 Physical Block (PB) contains identification and diagnosis parameters of the device

1 Flow Transducer Block

(TB-Flow) contains parameters and functions to control the flow measurement

1 Level Transducer Block

(TB-Level) contains parameters and functions to control the level measurement

1 Analog Input Function Block

(AI-FB) contains parameters and functions to control the measuring output;

provides the measuring value(s)

2 Totalizer Function Blocks

(Tot-FB) contains parameters and functions to control/provide the counter

value(s)

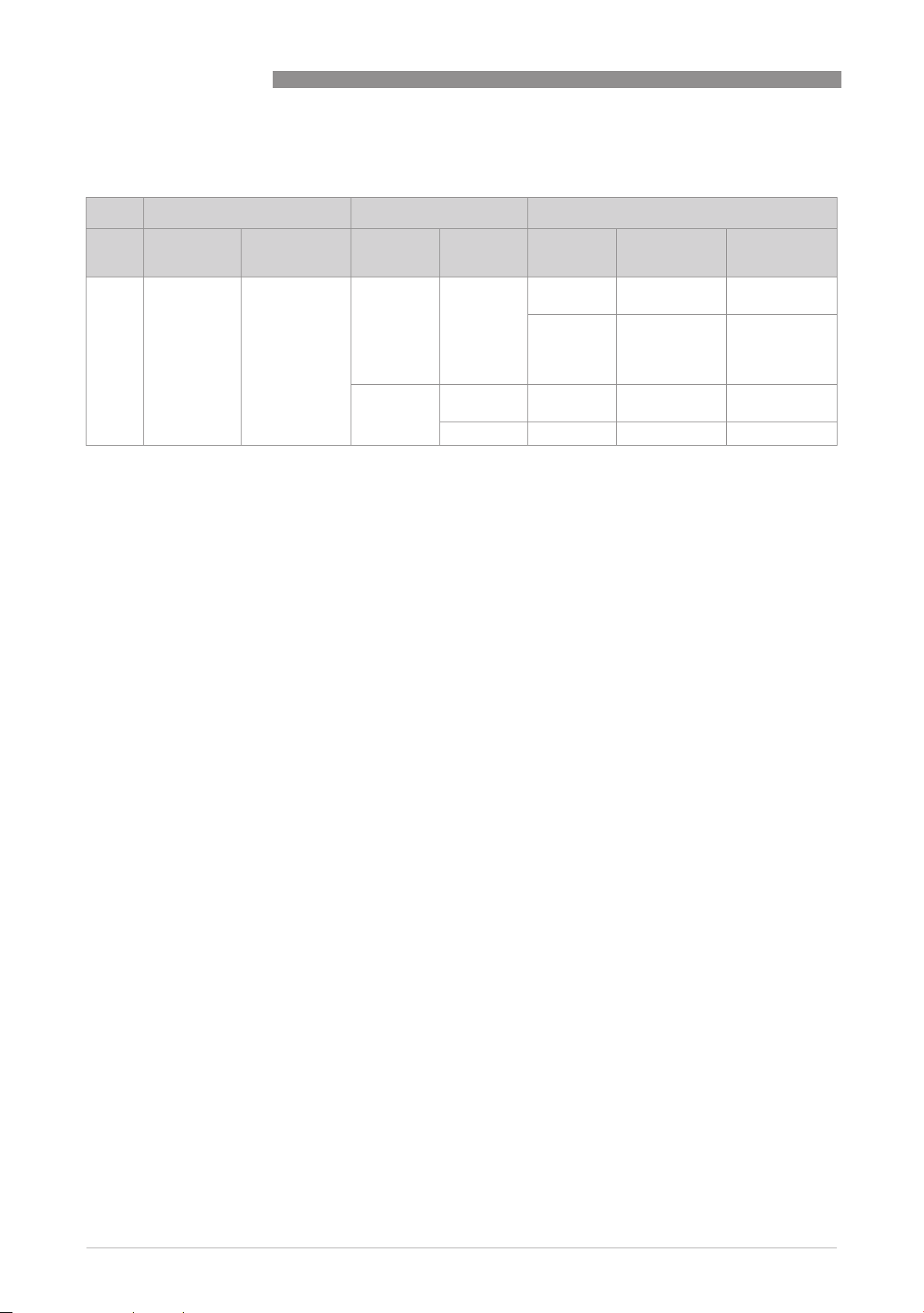

Slot

SlotSlot

Slot Module type

Module typeModule type

Module type Measuring data

Measuring dataMeasuring data

Measuring data 1

1AI-FB Volume flowrate (Default setting)

Mass flowrate

Board temperature

2Totalizer-FB Totalized volume flowrate (Default setting)

Totalized mass flowrate

3Totalizer-FB Totalized volume flowrate

Totalized mass flowrate (Default setting)

1Selection of measuring data can be changed by modifying the channel parameter via acyclic PROFIBUS services.

AD_H250_M40_PB_PA_R01_en_4002251801_PRT.book Page 5 Friday, March 21, 2014 1:14 PM