Addendum to Operating and Instruction Manual for “Modis” Converters

KROHNE Ltd •Rutherford Drive •Park Farm Industrial Estate •Wellingborough •Northamptonshire •NN8 6AE •UK

Tel. +44 1933 408 500 •Fax +44 1933 408 501•WWW.KROHNE.com Page 9 of 18

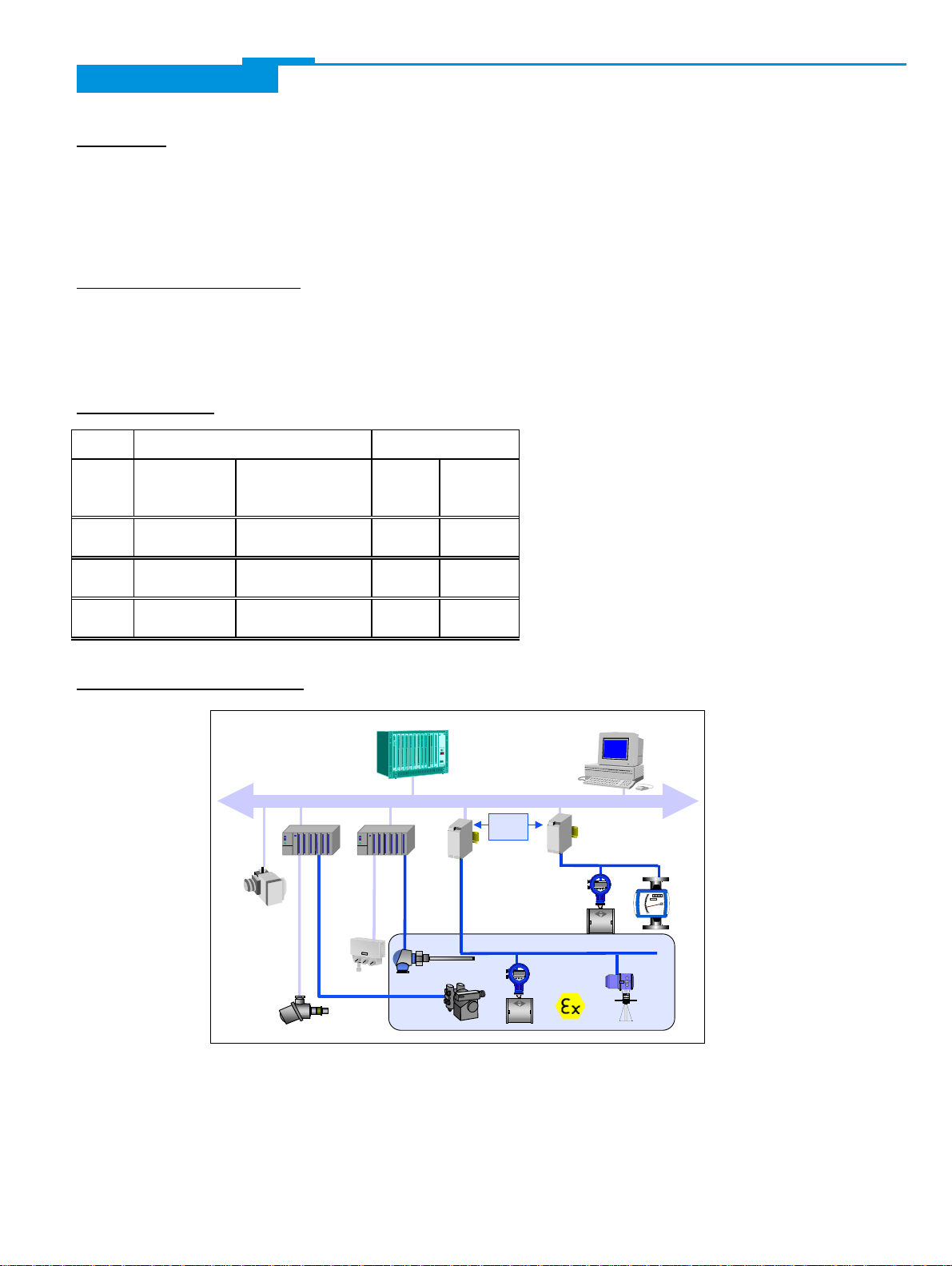

The PROFIBUS-PA is normally connected to a segment coupler, which, among other things,

carries out conversion to the PROFIBUS-DP. Here, it needs to be noted in particular that the

segment coupler is normally set to a fixed baud rate on the DP side.

Further information on the planning and Operation of PROFIBUS-PA networks is to be found

in the KROHNE brochure “PROFIBUS-PA networks”.

2.1 GSD File

All available GSD files of KROHNE devices – including those of the MFC 081 i or 085 i, of

course - are supplied together with each device. The GSD contains information that is needed

for project planning of the PROFIBUS-DP/PA communication network. The relevant data files

must be loaded into the project planning system/master system before start-up of the bus

system.

For example, the following applies to COMET 200 or COM PROFIBUS from Siemens:

•all GSD files (*.GSD) into the directory of the GSD files, e.g. *\GSD

•all BMP files (*.BMP) into the directory of the bit maps, e.g. *\BITMAPS

In STEP7, the GSD file is automatically copied into the respective directory with “install new

GSD” (in the HW-Config Menu: EXTRAS). After that, the bit map must be copied into the

directory *\SIEMENS\STEP7\S7data\Nsbmp. Following “catalogue updating” the device can

be placed in the project. This will then enable the cyclic communication (measured values and

status).

The MFC 081/085 i are supporting the entire PROFIBUS-PA profile V 3.0. All devices have

two ident-no. and two GSD files. Ident-no. “F701” belongs to the GSD file KROHF701.GSD

and includes the complete functionality of the mass flow meter. The use of the manufacturer

independent Ident-no. “9742” (GSD file “PA_9742.GSD”) allows the user an interchange with

other mass flow devices from other manufacturers.

PA_9742.GSD

The limited functionality of the GSD file includes four function blocks:

Mass flow rate, density, temperature and mass flow totalizer.

You need the PA_9742 to use this functionality. Before this, the communication has to be

projected and it has to be switched from “full functionality” to “interchangeable basic

configuration” by using a Master Class 2 Tool (IDENT_NUMBER_SELECTOR: Slot 0, Index

40 change byte value from 1 to 0). After this has been done, the device has to be projected by

using PA _9742.