CONTENTS

2 www.krohne.com 10/2012 - 4002257401 - QS IFC 050 R01 en

IFC 050

1 Safety instructions 3

2 Installation 4

2.1 Intended use ..................................................................................................................... 4

2.2 Scope of delivery............................................................................................................... 4

2.3 Storage ............................................................................................................................. 5

2.4 Transport .......................................................................................................................... 5

2.5 Installation specifications ................................................................................................5

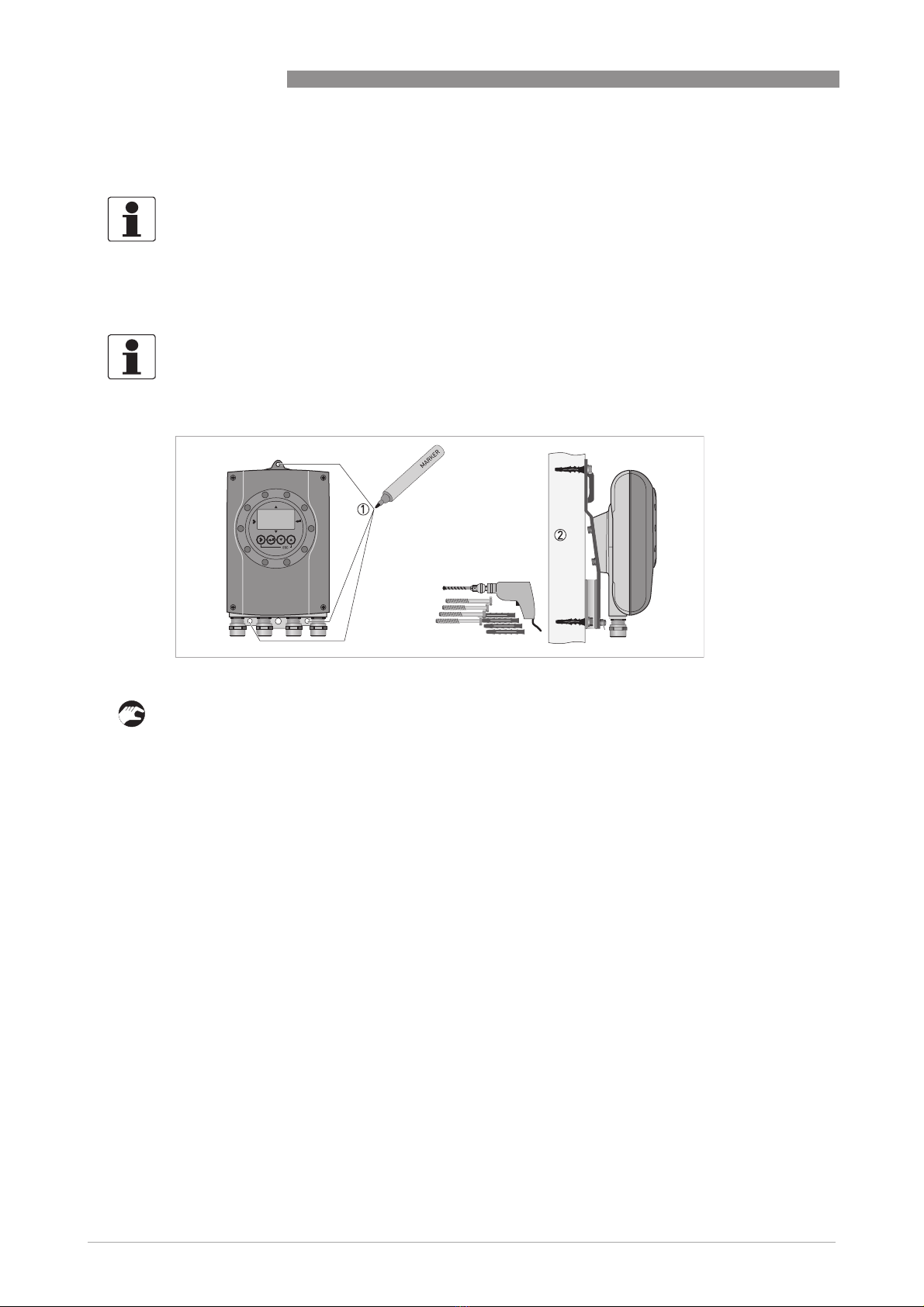

2.6 Mounting of the compact version..................................................................................... 6

2.7 Mounting of the wall housing, remote version ................................................................ 6

3 Electrical connections 8

3.1 Safety instructions............................................................................................................ 8

3.2 Important notes on electrical connection........................................................................ 8

3.3 Electrical cables for remote device versions, notes........................................................ 9

3.3.1 Notes on signal cable A .......................................................................................................... 9

3.3.2 Notes on field current cable C................................................................................................ 9

3.3.3 Requirements for signal cables provided by the customer ................................................. 10

3.4 Preparing the signal and field current cables ............................................................... 11

3.4.1 Signal cable A (type DS 300), construction........................................................................... 11

3.4.2 Preparing signal cable A, connection to signal converter ................................................... 12

3.4.3 Length of signal cable A........................................................................................................ 13

3.4.4 Preparing field current cable C, connection to signal converter......................................... 14

3.4.5 Preparing signal cable A, connection to measuring sensor................................................ 16

3.4.6 Preparing field current cable C, connection to measuring sensor ..................................... 17

3.5 Connecting the signal and field current cables............................................................. 18

3.5.1 Connecting the signal and field current cables to the signal converter, remote version... 18

3.5.2 Connection diagram for signal and field current cable ....................................................... 19

3.6 Grounding the measuring sensor .................................................................................. 20

3.7 Connecting the power supply......................................................................................... 20

3.8 Overview of outputs ........................................................................................................22

3.8.1 Description of the CG number .............................................................................................. 22

3.8.2 Fixed, non-alterable output versions ................................................................................... 22

3.9 Electrical connection of the outputs .............................................................................. 23

3.9.1 Electrical connection of the outputs.....................................................................................23

3.9.2 Laying electrical cables correctly......................................................................................... 24

4 Start-up 25

4.1 Switching on the power .................................................................................................. 25

4.2 Starting the signal converter ......................................................................................... 25

5 Notes 26