01/2022 – 4009110601 - QS MAC 100 R01 en

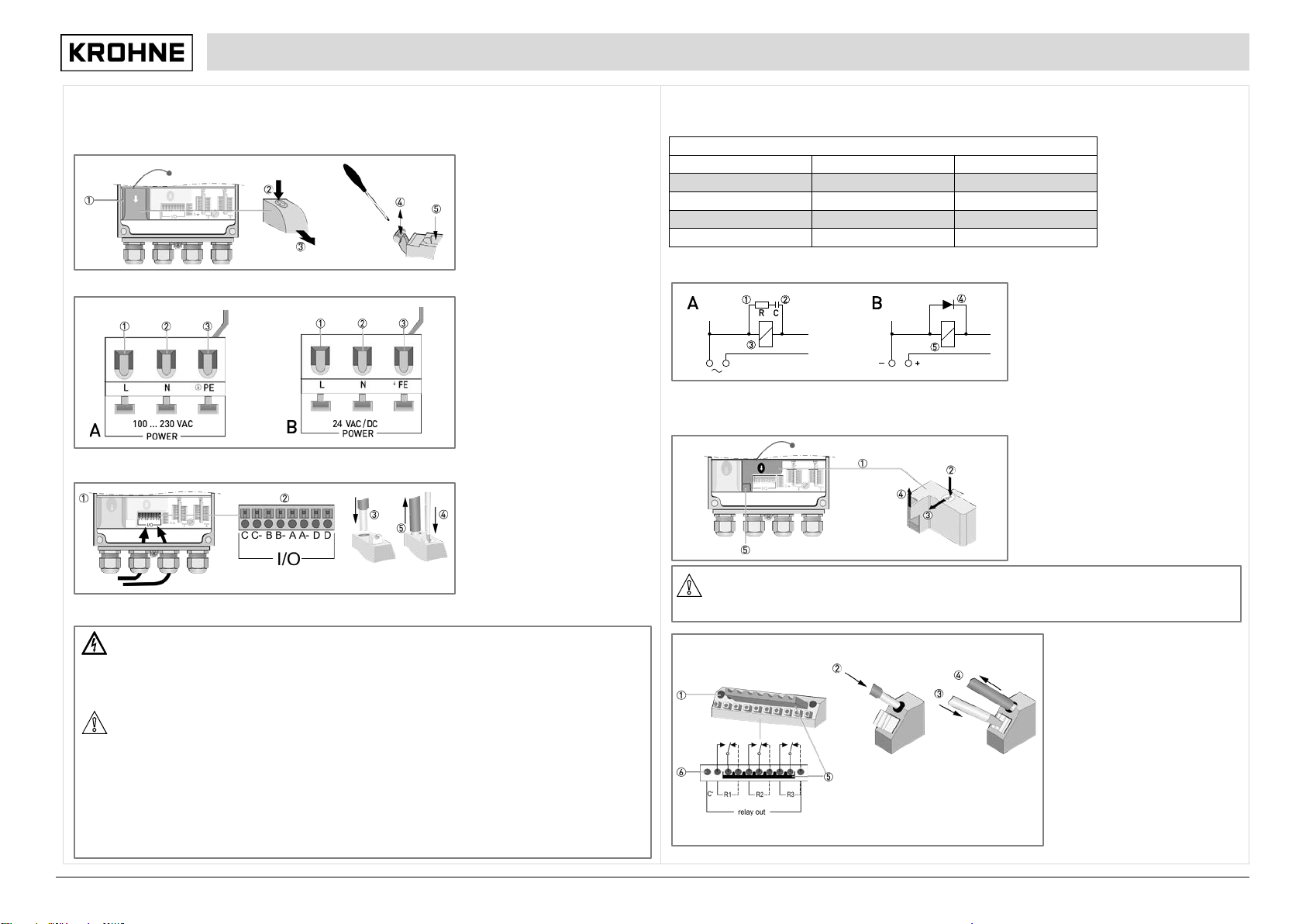

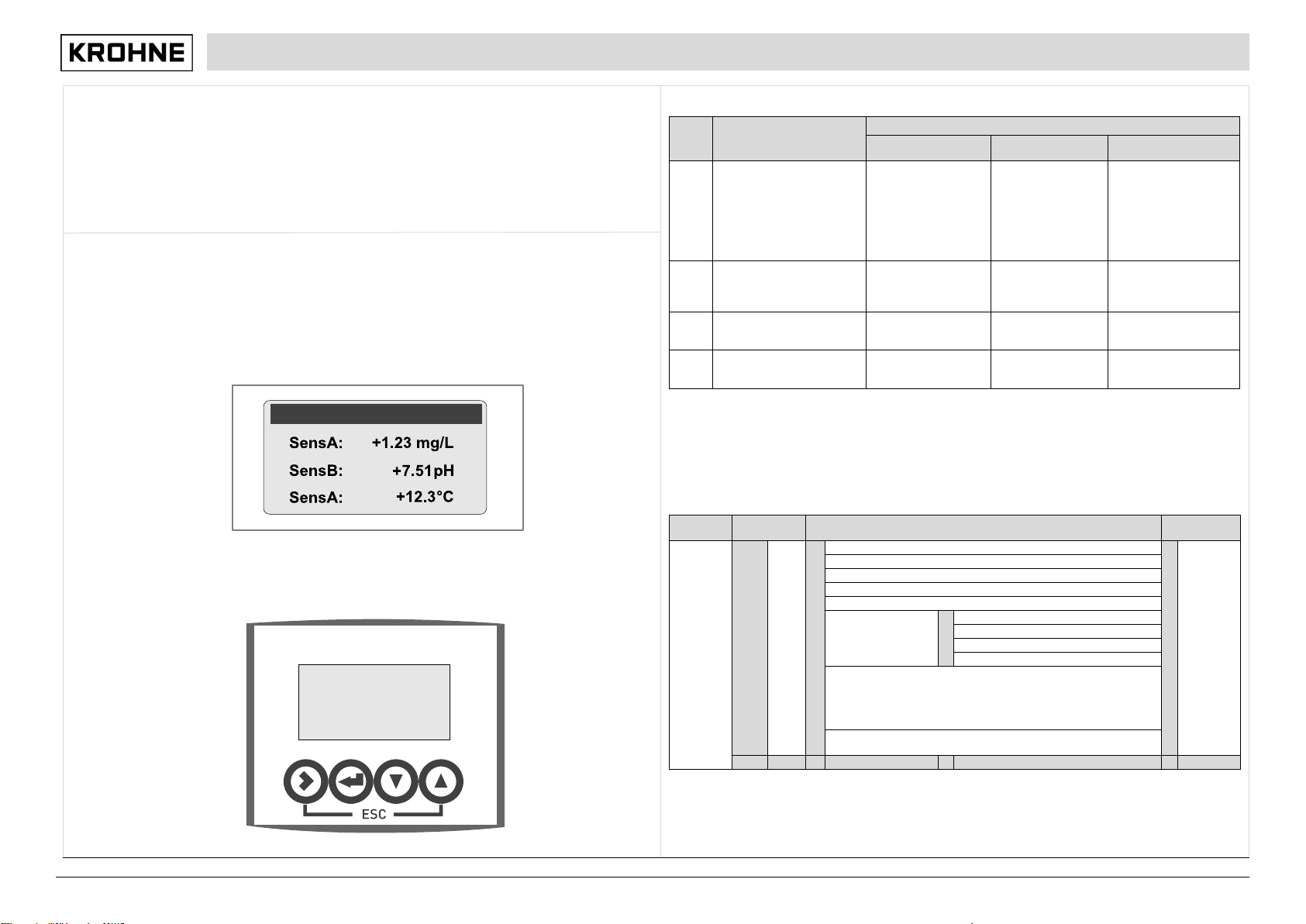

Connecting the power supply 100…230 VAC (fig. A) or 24 VAC/DC (fig. B)

Remove the cover of the power supply terminal by pressing it down and pulling forwards at the same time and ,

be careful and do not disrupt the retaining band (it prevents the cover from getting lost)!

Use a slotted screwdriver with a tip

of 3.5 x 0.5 mm / 0.14 x 0.02" to

push down the lever, connect the

wires to the terminals and pull up the

levers again and . Remount

cover.

Live (L)

Neutral (N)

Protective Earth (PE) or

Functional Earth (FE)

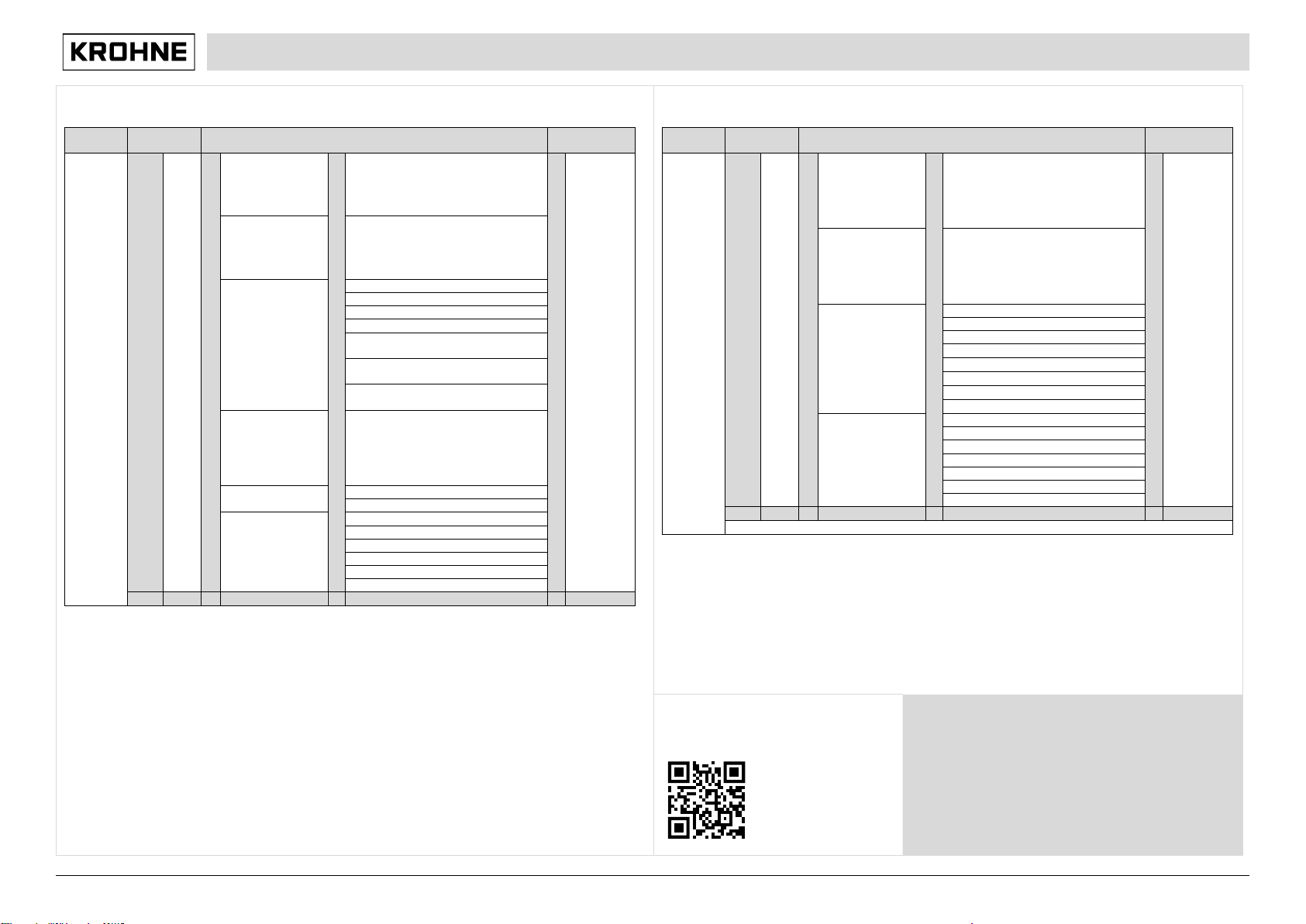

Connecting the current outputs

Conduct the cables with

prefabricated shielding through the

correct cable glands and .

Insert the cable into the terminal .

To remove the cable push the lever

down with a suitable tool and pull

the cable out of the terminal .

Connecting the relay outputs

In delivery condition, the relay contacts are also suitable for low signal currents (from approx. 1 mA). Please note that

the gold plating burns off during the switching operation when larger currents are used (from approx. 100 mA).

Afterwards, the relays can no longer reliably switch small currents!

Interference suppression (A = AC, B = DC)

Resistor, R = 47...390 Ω, see table before

Capacitor, C = 10...220 nF, see table

before (e.g. Siemens MKC B 81 921)

Relay coil

Free-wheeling diode

Relay coil

Required cable properties

• Maximum wire cross section: 1.5 mm2/ 0.06 square inch

• Minimum stripping length for wires: 8 mm / 0.31" Start to remove the cover of the relay outputs

by pressing it down .

Pull the cover forward , then upward out of

the clip and remove it.

Remove the cover of the earth terminal by

pulling it upwards .

You see the 10-pin terminal block which is

fitted with a connected bridge.

Connect the cables to the single relay

terminals (+).

To release a cable from the relay

terminals, first unlock the locking

device with a suitable tool and pull

out the cable .

If a switching voltage is applied to

connection "C" , relay contacts R1,

R2 and R3 are supplied in parallel

with the help of the link plug .

This allows the voltage switched from

the relays to be passed on. You can

remove the bridge if this supply is not

needed.

After you have connected all cables,

refasten the cover of the relay

outputs.

AC voltage: required capacitors and resistances for dejamming

60 mA 10 nF / 260 V 390 Ω/ 2 W

70 mA 47 nF / 260 V 22 Ω/ 2 W

1.0 A 220 nF / 260 V 47 Ω/ 2 W

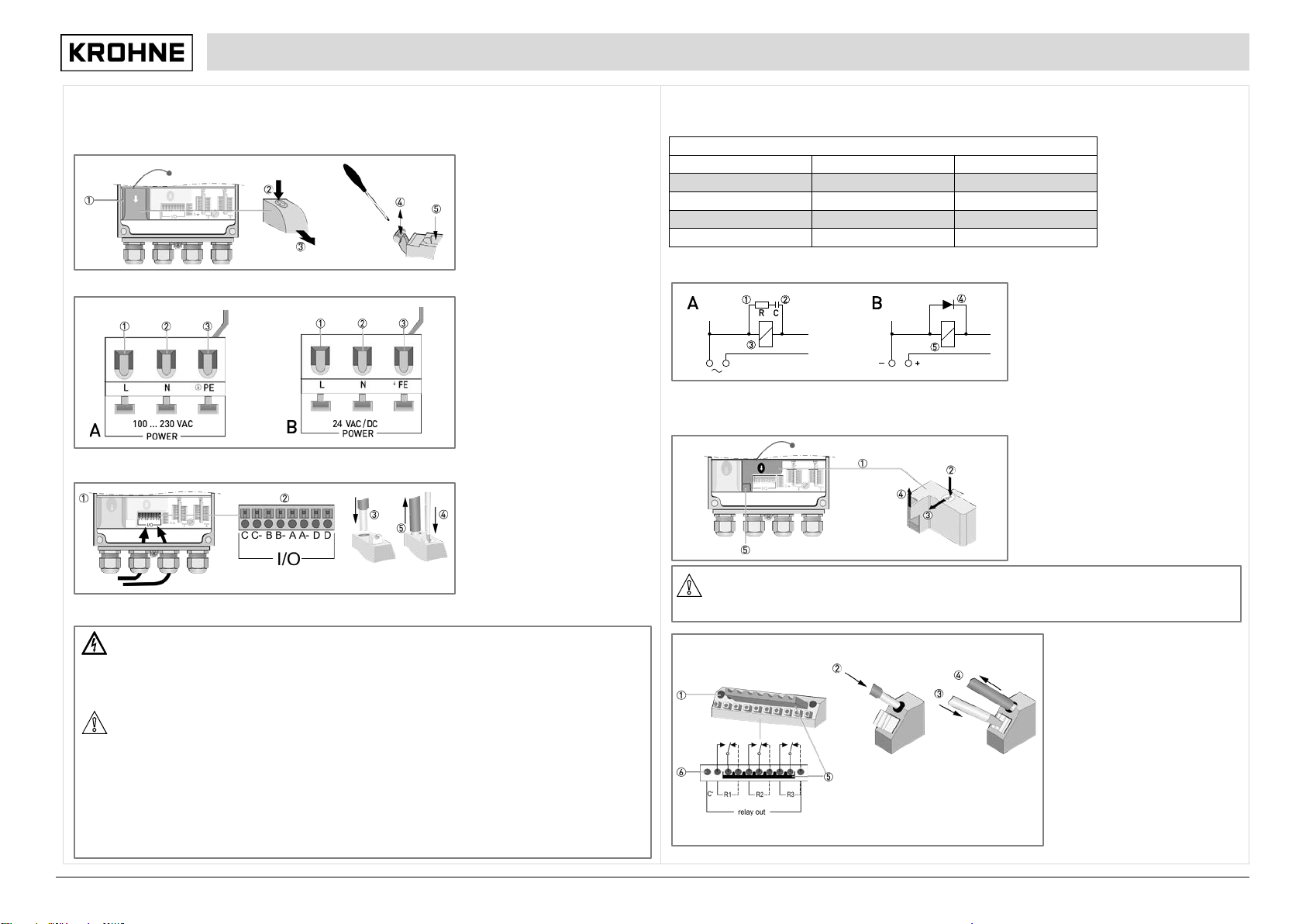

Danger:

To avoid dangerous voltages, the switching voltage for the relay contacts must fulfill one of the following

conditions: it must

either originate from the same network as the signal converter power supply including pre-

fuse and separator or come from a SELV or PELV network. When installing, always comply with the

prevailing national and international regulations and standards.

ON!

If you want to switch inductive loads (even relays or protection coils), you always have to dejam them!

Otherwise there may occur interferences with the measuring signal. Also note the following items:

If you use DC voltage, dejam the relay coil with a free-wheeling diode; refer to the following table and the

following drawing "Interference suppression"!

If dejamming is not possible, you have to assure that the relay contact is protected by a RC protection

circuit! Also refer to the following table.

If you use potential-free relay outputs, assure that a suitable shut-off device and a pre-fuse is installed in

the feed line on site.

When switching inductive loads, the manufacturer recommends a protective circuit to avoid unnecessarily

high contact burn on the relay contact!

he screw under the cover is not to be used as a cable connection. Do not loosen or remove the cover of