GB-2

GB

Checking the usage

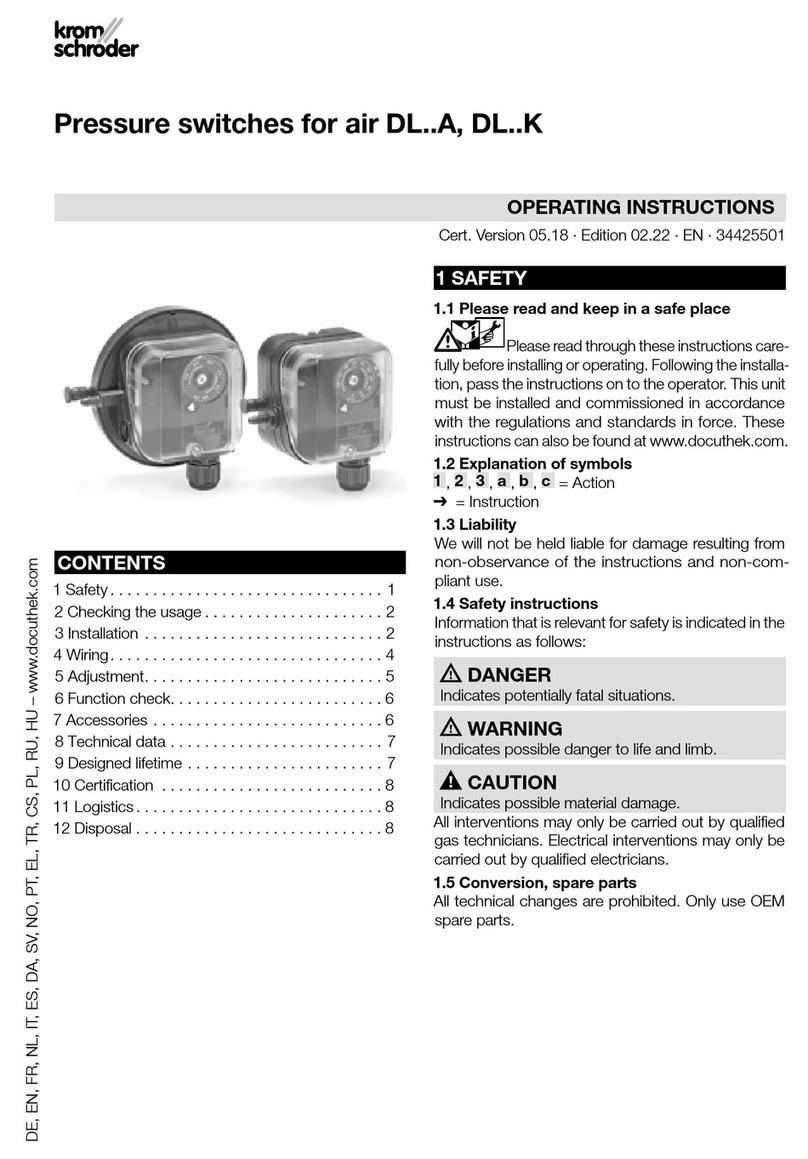

DL ,5 – 3A, DL 3K, DL 5 – 50A, DL 5 – 50K

For monitoring positive, negative or differential air or

flue gas pressures.

This function is only guaranteed when used within

the specified limits– see page7 (Technical data).

Any other use is considered as non-compliant.

Type code

Code Description

DL Pressure switch for air

,5 – 50 Max. setting in mbar

K

A

With tube connection and hand wheel

Additionally with Rp¼connection

(optional: Rp

1/8

)

TT-product

-3

-4

-5

-6

-9

Electrical connection

via screw terminals

via screw terminals, IP 65

4-pin plug, without socket

4-pin plug, with socket

4-pin plug, with socket, IP 65

K

T

T

N

Red/green pilot LED for 24 V DC/AC

Blue pilot lamp for 230 V AC

Red/green pilot LED for 230 V AC

Blue pilot lamp for 120 V AC

AExternal adjustment

WZ-angle bracket

Part designations

1

22

3

4

Upper housing section with cover

Lower housing section

3Hand wheel

4M16 cable gland

Type label

DL

CE – 0085AP0466

2

13

D-49018 Osnabrück, Germany

Max. inlet pressure = withstand pressure, mains volt-

age, ambient temperature, enclosure: see type label.

Installation

CAUTION

Please observe the following to ensure that the DL

is not damaged during installation and operation:

– Use approved sealing material only.

– Note the max. medium and ambient tempera-

tures, see page7 (Technical data).

– Condensation must not be allowed to get into

the housing (if possible, install pipework with an

ascending gradient). Otherwise, there is a risk of

icing of condensation at subzero temperatures,

the switching point shifting or corrosion in the

device which can lead to malfunctions.

– Protect the connections against dirt or moisture

in the medium to be measured or the surround-

ing air. If necessary, install a filter.

– In case of highly fluctuating pressures, install a

damping nozzle/restrictor orifice.

– When installing outdoors, place the DL in a

roofed area and protect from direct sunlight

(even IP65 version). To avoid condensation,

the cover with pressure equalization element

can be used on some types.

– In the case of an uneven mounting surface, se-

cure the pressure switch to the mounting plate

or air duct with only two screws on the same

side in order to avoid subjecting the pressure

switch to mechanical stress.

– When using silicone tubes, only use silicone

tubes which have been sufficiently cured. Va-

pours containing silicone can adversely affect

the functioning of electrical contacts.

– In the case of high humidity or aggressive gas

components, we recommend using a pressure

switch with gold contact due to its higher resist-

ance to corrosion. Closed-circuit current moni-

toring is recommended under difficult operating

conditions.

▷

The DL must not be in contact with masonry.

Minimum clearance 20mm.

▷Ensure that there is sufficient installation space.

▷Ensure unobstructed view of the hand wheel.

▷

Installation in the vertical or horizontal position, or

upside down, preferably with vertical diaphragm.

If installed in a vertical position, the switching

pointpSwill correspond to the scale valueSK.