Contents

3 of 48

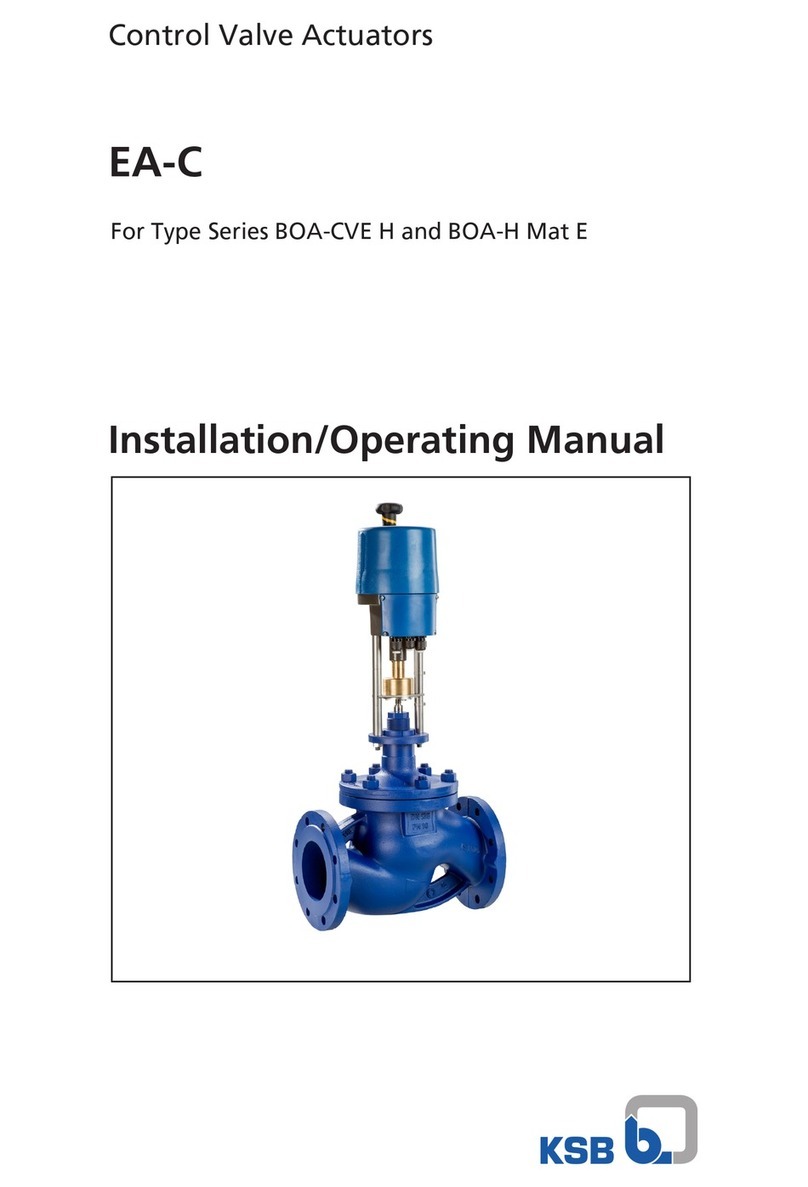

EA-C / EA-B

Contents

1 General.................................................................................................................................................... 5

1.1 Principles ...........................................................................................................................................................5

1.2 Target group.....................................................................................................................................................5

1.3 Symbols .............................................................................................................................................................5

2 Safety...................................................................................................................................................... 6

2.1 Key to safety symbols/markings.......................................................................................................................6

2.2 General..............................................................................................................................................................6

2.3 Intended use .....................................................................................................................................................7

2.3.1 Prevention of foreseeable misuse.......................................................................................................7

2.4 Personnel qualification and training...............................................................................................................7

2.5 Consequences and risks caused by non-compliance with this operating manual........................................7

2.6 Safety awareness ..............................................................................................................................................7

2.7 Safety information for the user/operator.......................................................................................................8

2.8 Safety information for maintenance, inspection and installation ................................................................8

2.9 Unauthorised modes of operation..................................................................................................................8

3 Transport/Storage/Disposal .................................................................................................................. 9

3.1 Checking the condition upon delivery............................................................................................................9

3.2 Transport...........................................................................................................................................................9

3.3 Storage/preservation........................................................................................................................................9

3.4 Disposal/recycling .............................................................................................................................................9

4 Description............................................................................................................................................ 10

4.1 General description ........................................................................................................................................10

4.2 Designation.....................................................................................................................................................10

4.3 Name plate......................................................................................................................................................10

4.4 Design details..................................................................................................................................................11

4.5 Function ..........................................................................................................................................................12

4.6 Noise characteristics .......................................................................................................................................13

5 Installation............................................................................................................................................ 14

5.1 General information/Safety regulations .......................................................................................................14

5.2 Checking prior to installation........................................................................................................................15

5.3 Installation position........................................................................................................................................15

5.4 Manual override .............................................................................................................................................16

5.5 Mounting actuator type EA-B12...................................................................................................................17

5.5.1 Mounting type EA-B12 .....................................................................................................................17

5.5.2 Electrical connection..........................................................................................................................18

5.6 Mounting actuator type EA-C20 to 140.......................................................................................................20

5.6.1 Fitting the actuator............................................................................................................................20

5.6.2 Electrical connection..........................................................................................................................21

5.6.3 Mains connection...............................................................................................................................23

5.6.4 Interfaces ............................................................................................................................................23

5.6.5 Heating resistor (optional) ................................................................................................................24

5.6.6 Limit switching ...................................................................................................................................25

5.6.6.1 Continuous-action actuators.........................................................................................................25

5.6.6.2 230V, 3-point actuators................................................................................................................25

5.6.7 Operation ...........................................................................................................................................26

6 Commissioning/Start-up/Shutdown................................................................................................... 27

6.1 Prerequisites for commissioning/start-up......................................................................................................27

6.2 Commissioning/Start-up.................................................................................................................................27

6.2.1 Automatic commissioning of EA-B actuators...................................................................................27

6.2.2 Automatic commissioning of EA-C actuators (continuous-action and 24VAC/DC 3-point

actuators)............................................................................................................................................27

6.2.3 Mechanical commissioning of 3-point actuators .............................................................................28

6.3 Operating limits..............................................................................................................................................28