Submersible Motor Pumps (150 mm and above)

6

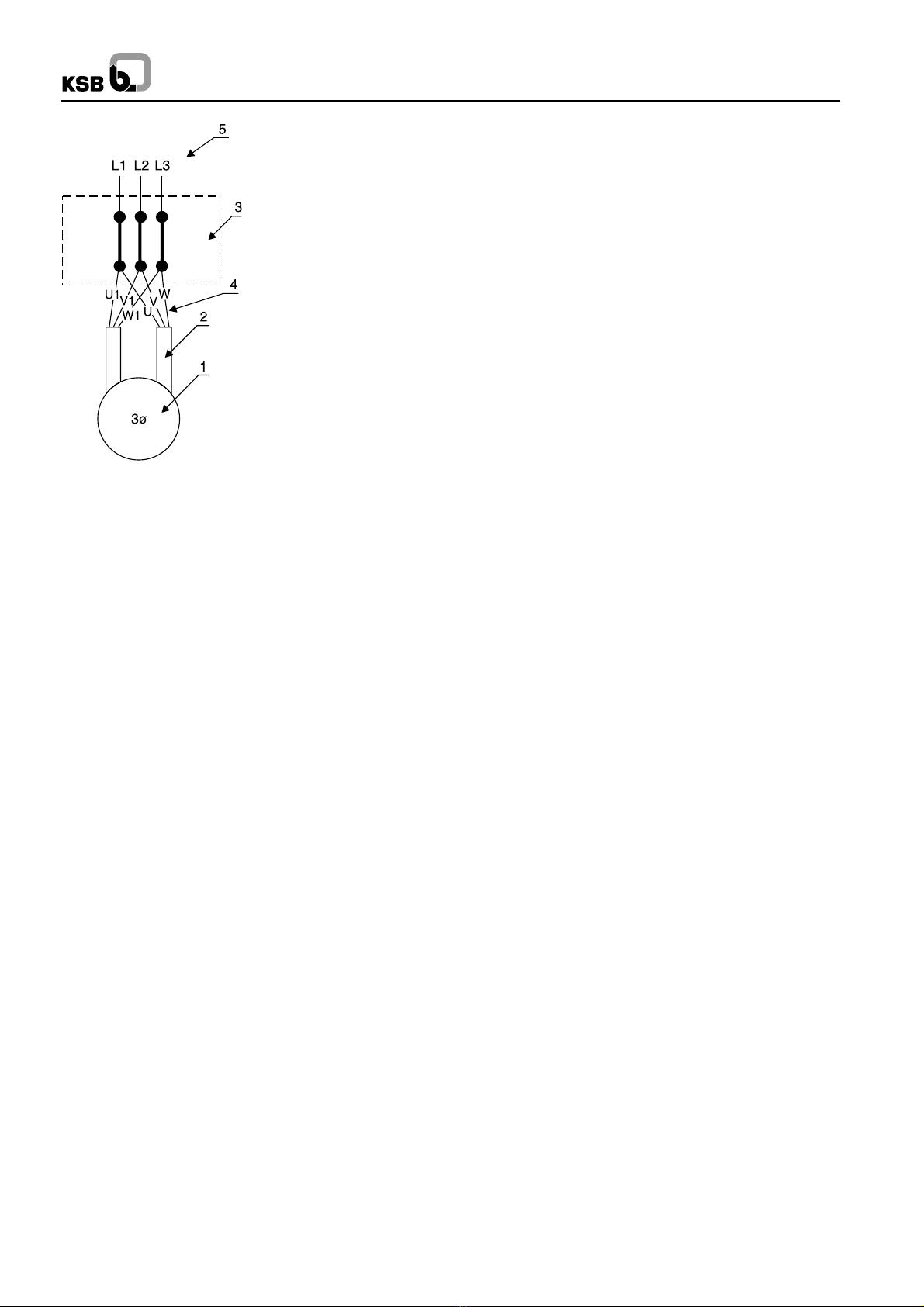

1. Submersible motor

2. Cable

3. Switchgear panel

4. Cable leads

5. Incoming supply

Fig. 9 : Two cable in parallel motor connection

7.0 Commissioning and start up

7.1 Verification of power supply

Verify the voltage and frequency of main supply with the data

specified on the motor nameplate. If it is not matching then

consult with concerned electrical authority.

7.2 Trip circuit for over current

A temperature compensated over current relay to be provided

in the control panel. For the Relay setting, please refer the value

of rated current specified on the nameplate.

7.3 Protection against electric shock

The earth conductor to be connected to the earthing Lug,

provided at upper part of the motor. The operator / user shall be

responsible for proper connection of the earthed conductor and

of control unit at site.

7.4 Installation of water level guard

Install a water level guard for dry running protection to avoid

the damage of pumpset in case of fluctuation in water level.

7.5 Checking the direction of rotation

To determine the correct direction of rotation of the pumpset,

•Close the discharge valve and let pumpset run in both the

directions (Direction can be changed by reversing the two

phases in the supply connection) for a short. In both cases

check the flow by opening the discharge valve.(Higher flow

rate corresponds to the correct direction of rotation.) OR

•Check the discharge pressure in both the directions of

rotations (by using pressure gauge). The higher value of

pressure corresponds to the correct direction of rotation.

7.6 Discharge valve position during initial start-

up

During initial startup, the pumpset should run for 10 minutes

approximately with discharge valve slightly open (approx.1/3

of full opening) and examined for the sand contains. If the sand

contain is more than 50 mg / liter then it is recommended to run

the pumpset till sand contain fall to the unnoticeable

level.Otherwise sand will block the pump internals resulting in

damage.

7.7 Operation against a closed discharge valve

Pumpset should not be allowed to run against a closed discharge

valve for more than 5 minutes. This is because the water trapped

in the pump will heat up very quickly and this heat will transfer

to the motor, where it will cause the winding damage.

7.8 Operation against a throttled discharge

valve

If the pump set operated against throttled discharge valve for a

prolonged period of time, the flow must not fall below Qmin. OR

be at least 10% of the flow at best efficiency point* (BEP). This

needs to be ensured in order to reduce noisy operation and the

overheating of the pump set.

*For best efficiency point (BEP) of the characteristic curve

consult KSB / Dealer.

7.9 Operating limits of pump

Operational safety requirements stipulate that pump should only

be operated continuously within the flow rate and pump head

limits, specified on the nameplate. Otherwise ±10% of best

efficiency flow rate should be the pump operation range,

provided that motor is not overloaded. (To ensure this, check

the motor current which should not exceed as specified on

nameplate).

7.10 Start-up frequency

In order to prevent the overheating of motor winding, startup

frequency is restricted up to 15 per hour. (Ensure minimum 3

min. down time between switch OFF & switch ON again).

7.11 Interruptions / Shutdown periods

For prolonged service, the pump should not be allowed to remain

idle / stationary in water for more than 8 to 10 days, otherwise

fine deposits like lime, iron and other substances will settle in

the bearings and impeller gaps. This might block the pump rotor.

If operating conditions require the pump to remain not in use for

a long period, it is recommended to run the pump atleast 10 to

15 minutes in a week. This will enable the pump to resume

instant service at any time.

8.0 Maintenance & Service

8.1 Supervision of Operation

Basically submersible pumpset require no supervision or

maintenance during operation. However the current absorbed

by the motor should be checked from time to time on the

ammeter, also the total head on the pressure gauge in order to

confirm that these instruments indicate the same values as at

the start of operation and do not exceed those indicated on the

nameplate.

8.2 Storage of used pumpset

Always store the motor in upright position and away from the

direct sunlight, heat, dust and frost.For prolonged storage (more

than 1 year), pump should be dismntaled, cleaned and

reassembled. Before reassembly, all the rubbing and sliding

surfaces (except rubber bearings) should be well coated with

graphite base lubricant. On no account, use any grease

containing acid for this purpose.