4Mounting

4.1General instructions

The note of the following general safety instructions:

lDismount the lock fitting only in unpressurized condition

lUse only suitable graphite gasket rings.Make sure that the

graphite gasket rings are not damage.Damaged rings are

no longer tight.If you are not sure,use new rings.

lOnly use approved hexagon screws DIN 912 M6x25 of

A4-70 according to AD leaflet W2.The corresponding

spring rings B6must be made of A4according to DIN 7980.

lGrease the thread and the support of the terminal screws

with a suitable lubricant.The lubricant must be suitable for

material combination 316L/316Land for a temperature

range of -50 …+250°C(-58 …+482°F)e.g.Varybond

type NSS-16/7.The threads are already supplied with a

lubricant.

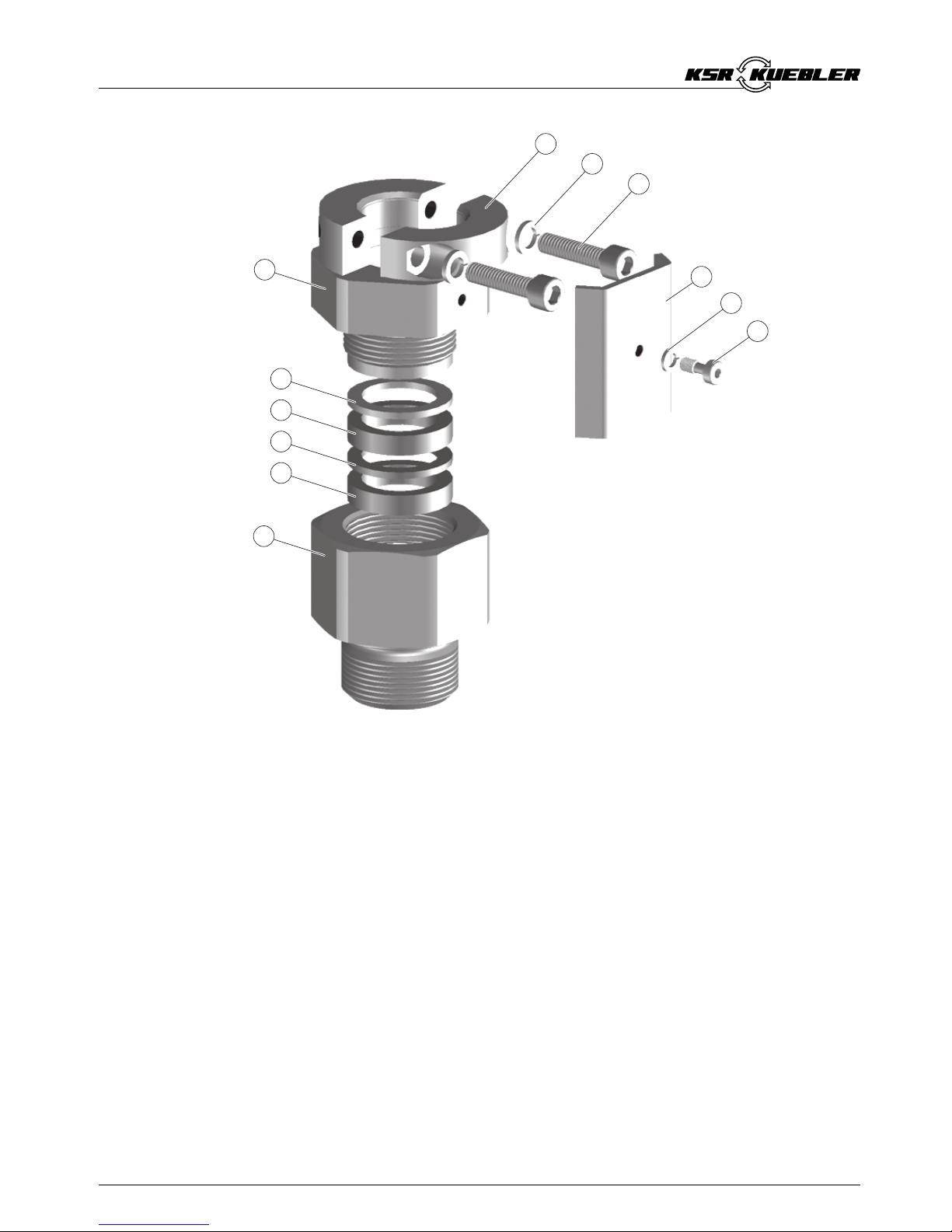

4.2Mounting sequence

The lock fitting is already premounted.

The numbers in brackets refer to the following illustration.

1Loosen the screw (6)and remove the locking bracket (4)

2Screw mounting boss (7)with a resistant seal ring into the

thread of the vessel and tighten the mounting boss (7)on

the hexagon (SW 41 or SW 60)

3Clean the connection tube of the sensor and the surfaces

of the clamp (1)as well as the pressure screw (11)

carefully and remove grease,oil and dirt.Insert the sensor

into the lock fitting.Slide the tube into the requested

position and hold it

4Make sure that the sensor is in the correct position (height).

The height adjustment of the sensor determines also the

switching point

5Tighten the pressure screw (11)with a torque 70 ±10 Nm

(51 ±7lbf ft)

6Continue to turn the pressure screw (11)clockwise until the

hexagon surfaces of the pressure screw (11)and the

mounting boss (7)correspond (max.1/6turn)

6Lock fitting ARV-TF633.2--pressure range:-1…16 bar

Mounting

32042-EN-060620