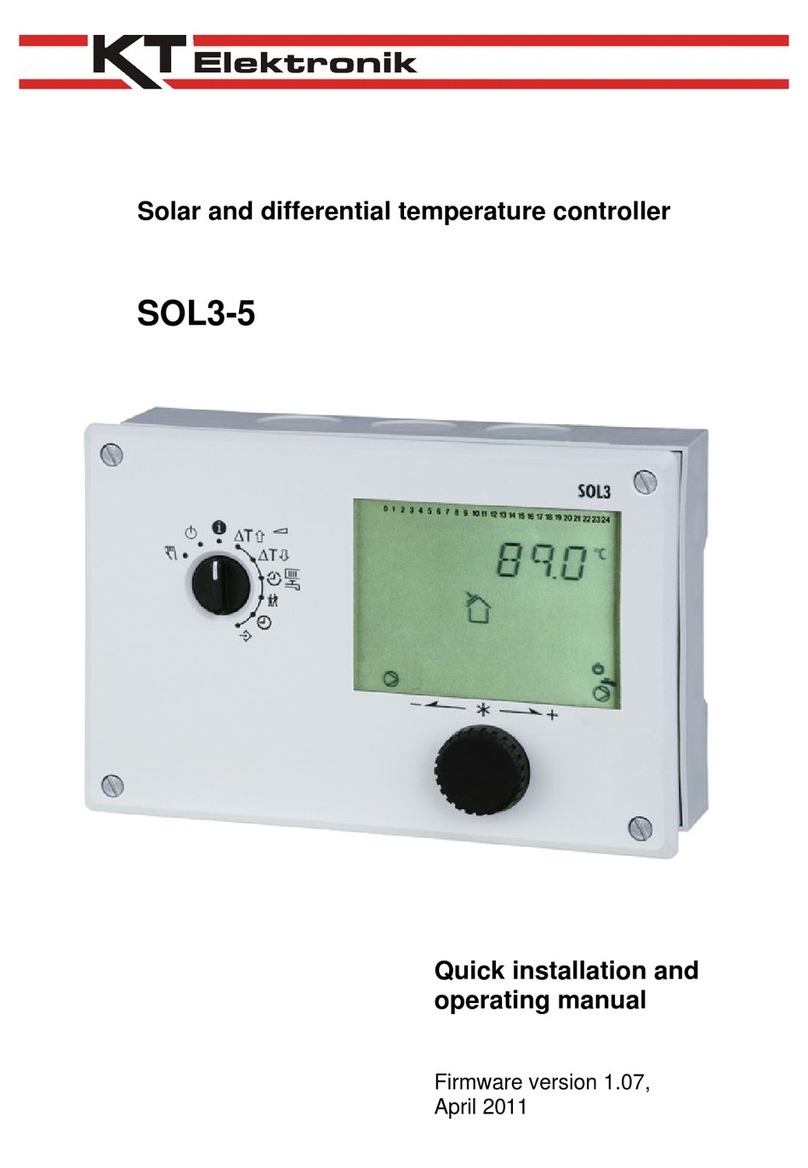

Quick installation and operating manual KT-Elektronik

Check and modify times-of-use

There are three independent sets of times-of-use for:

heating circuit, hot water circulation, auxilary heating

For systems that do not contain the functional groups mentioned, this chapter

has no meaning, the display and input of times-of-use is not offered by the

SOL3-5

Three times-of-use can be set for each day of the week If only one time-of-use is

required, start and stop of second time-of-use must be equal

Set rotary switch to times-of-use ;

Times-of-use for heating circiut is graphicaly shown, name of times-of-use is displayed inverted

Turn rotary pushbutton: Select times-of-use (heating circuit, hot water circulation, auxilary heating)

Push rotary pushbutton: Confirm fo modify times-of-use - heating circuit

Day of week interval is shown inverted for the selection

Turn rotary pushbutton: Select day of week (Monday to Sunday or single days)

Push rotary pushbutton: Confirm day of week or interval

Start of first time-of-use is shown inverted

Turn rotary pushbutton: Modify Start of first time-of-use

Push rotary pushbutton: Confirm Start of first time-of-use

Stop of first time-of-use is shown inverted

Turn rotary pushbutton: Modify Stop of first time-of-use

Push rotary pushbutton: Confirm Stop of first time-of-use; Modification of first time-of-use finished

Day of week interval is shown inverted for the selection

Set rotary switch to Information level

Check and set party mode

Using the Party mode function, the controller continues or activates the day

mode during the time when the party timer is active, regardless of the

programmed times-of-use The activation of the party mode (count down) starts

with turning the rotary switch to any operating mode position (e g information

level) When the party timer has elapsed, the party mode timer is reset to 00:00

The party mode counts down in steps of 15 minutes and ranges up to 48 hours

Set rotary switch to party mode stellen;

Times-of-use for heating circiut is graphicaly shown, name of times-of-use is displayed inverted

Push rotary pushbutton: Confirm fo modify party timer - heating circuit

Party timer of heating circuit is in digits displayed inverted an graphicaly shown (black)

Turn rotary pushbutton: Modify party timer

Push rotary pushbutton: Confirm party timer

Set rotary switch to Information level

10 KA_37386_SOL3-5_EN001