4 L1216285 • Rev BC • Sep 2015 © Danfoss, 2015-09

WWarning

Alle mærker og typer af retningsventiler – også proportional ventiler – kan svigte og forårsage alvorlig skade. Det er derfor

vigtigt at analysere maskinen i alle enkeltheder.

Da proportionalventiler anvendes under mange forskellige driftsbetingelser og i mange forskellige maskiner, er det alene

maskinproducentens ansvar at træe det endelige produktvalg og sikre at samtlige maskinens krav til ydelse, sikkerhed og

advarsler er opfyldt. Ved valg af reguleringssystem – og sikkerhedsniveau – kan man f.eks. støtte sig til EN954-1

(sikkerhedsrelaterede bestanddele i reguleringssystemet.)

Alle Fabrikate und Typen von Wegeventilen – einschließlich Proportionalventile – können versagen und schlimme Unfälle

verursachen. Es ist daher wichtig, die Anwendung in allen Details zu analysieren.

Weil Proportionalventile unter vielen unterschiedlichen Arbeitsbedingungen und in vielen verschiedenen Anwendungen

benutzt werden, trägt allein der Maschinenhersteller die Verantwortung für seine endgültige Wahl von Produkt, und er ist

ebenfalls dafür verantwortlich, dass alle Leistungs-, Sicherheits- und Warnungsanforderungen an seine Maschine erfüllt sind.

Zur Wahl vom Reglersystem und Sicherheitsniveau kann man sich z.B. auf EN954-1 stützen.

All marks and brands of valves – inclusive proportional valves – can fail and cause serious damage. It is therefore important to

analyse all aspects of the application.

Because the proportional valves are used in many dierent operation conditions and applications, the manufacturer of the

application is alone responsible for making the nal selection of the products – and assuring that all performance, safety and

warning requirements of the application are met. The process of choosing the control system – and safety level – could e.g. be

governed by EN 954-1 (Safety related parts of control system). See also Technical information for PVE series 4.

Tous les distributeurs - y compris les distributeurs proportionnels - peuvent tomber en panne et entraîner de sérieux dommages.

C’est la raison pour laquelle il est important d’analyser chaque aspect de l’application. Les vannes proportionnelles étant

utilisées dans de nombreuses conditions d’exploitation et applications diérentes, le fabricant de l’application porte l’entière

responsabilité de la sélection nale des produits et du respect des exigences en matière de rendement, de sécurité et

d’avertissement. Le choix du système de commande – et du niveau de sécurité – peut être fait par exemple sur la base de la

norme EN 954-1 (parties du système de commande relatives à la sécurité). Se reporter également à Information technique pour

PVE série 4.

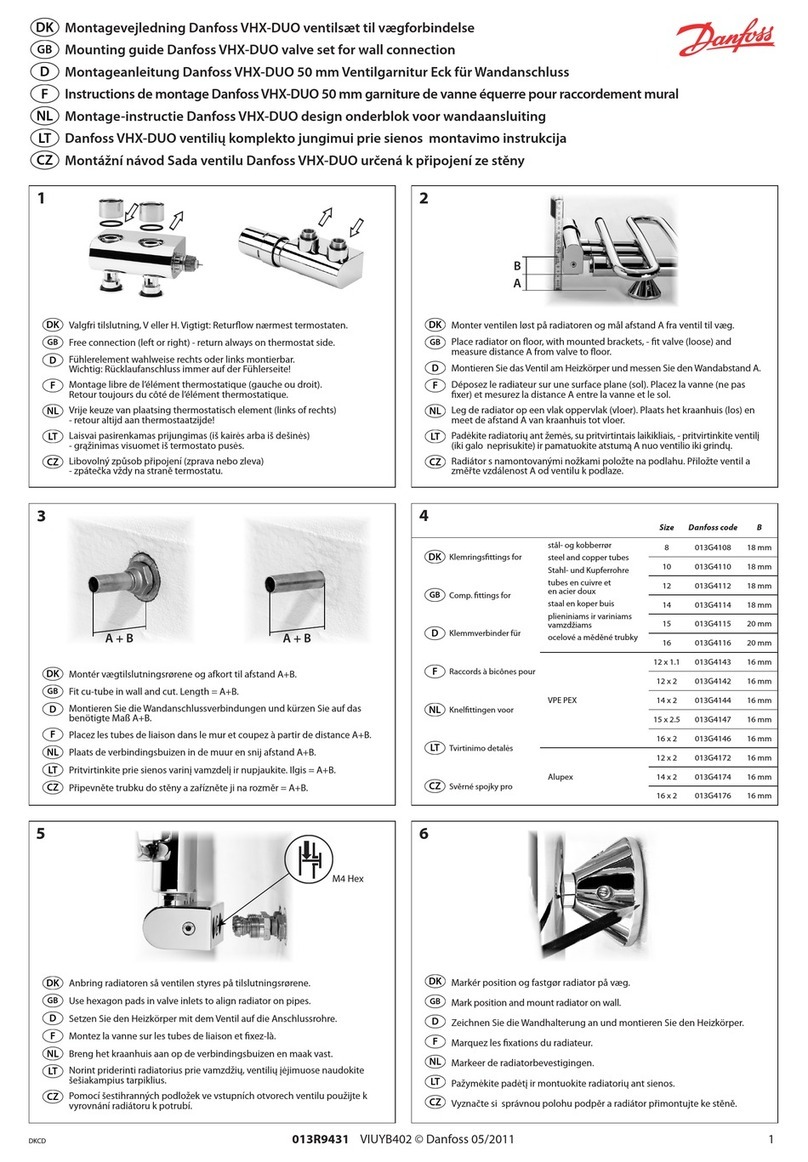

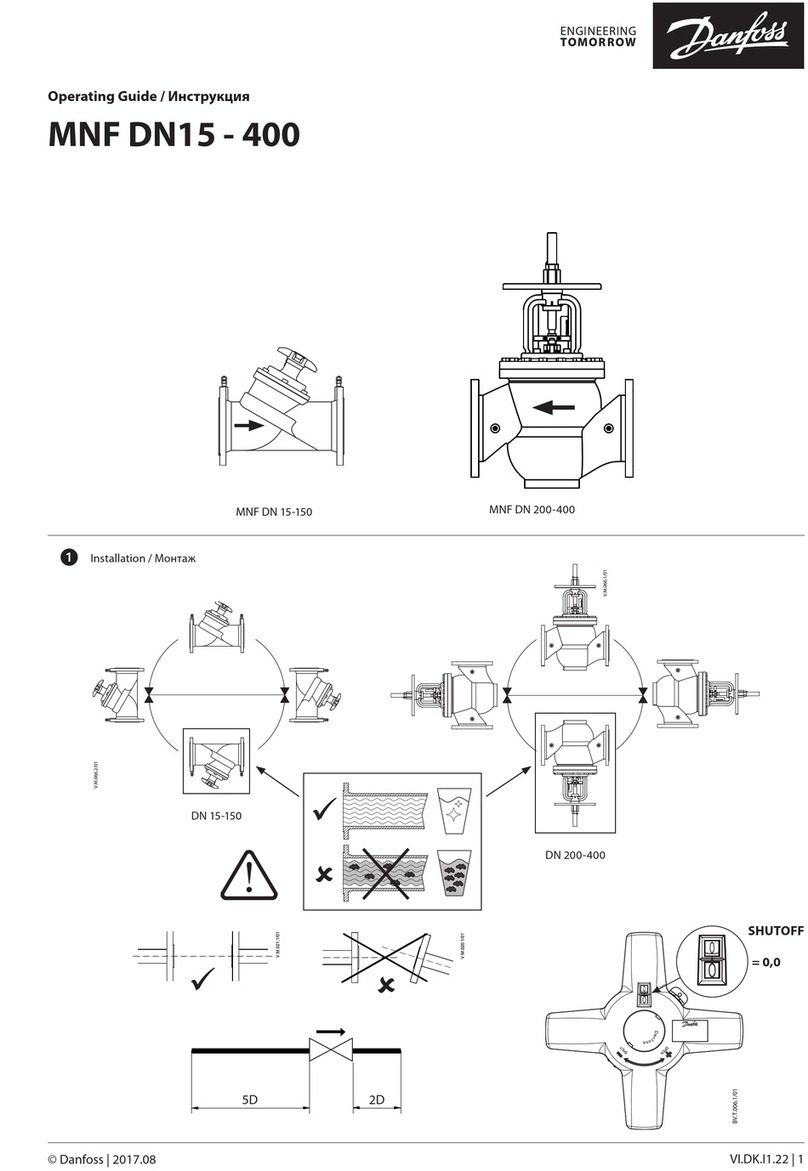

Udluftning

Hvis gruppen er monteret vertikalt, anbefales det at udlufte ved

justerskruer (Pos.A)

Bemærk: Ved PVEA kan det, pga.dens hydrauliske opbygning,

være påkrævet at foretage udluftning.

Bleeding

If the group is installed vertically, it is recommended to bleed it

at the adjusting screws (Pos.A)

Note: Because of the hydraulic build-up of PVEA, it may be

necessary to bleed the PVM.

Entlüftung

Wenn die Gruppe vertikal montiert ist, empfehlen wir an den

Justierschrauben zu entlüften (Pos.A)

Beachte: Wegen des hydraulischen Aufbaus von PVEA kann eine

Entlüftung erforderlich sein.

Purge

Si l'ensemble est monté verticalement, il est recommandé de le

purger au moyen des vis d'ajustage (Pos.A)

Nb! En raison du système hydraulique des PVEAs il peut s'avérer

nécessaire de purger.

Beskyttelse

Alle PVE-moduler overholder tæthedsgrad IP67 i henhold til

IEC 529. Det anbefales dog, at PVE’en på særligt udsatte steder

beskyttes i form af en afskærmning eller lignende.

Schutzart

Alle PVE-Module erfüllen die Schutzart IP67 gemäß IEC 529. Es

ist jedoch empfehlenswert, der PVE in besonders ausgesetzten

Einsatzbereichen mit einer Abschirmung oder dergleichen zu

schützen.

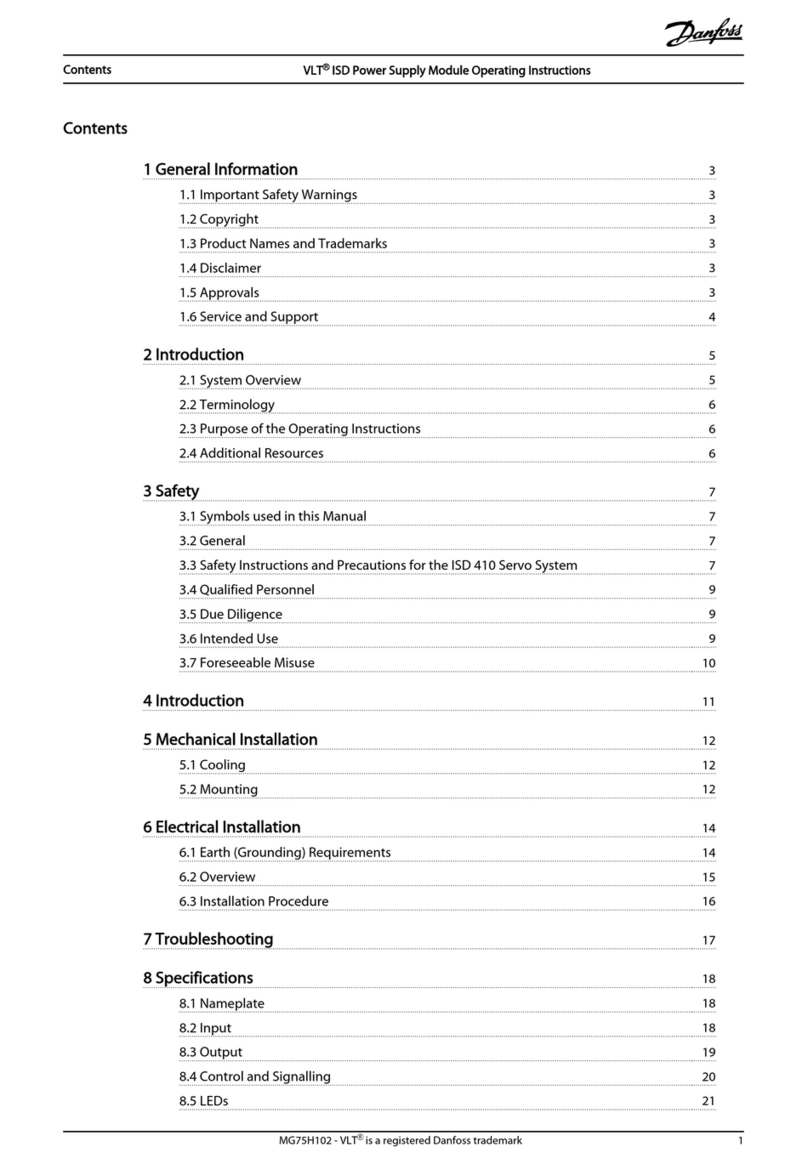

Protection

All PVE modules comply with protection class IP67 in accordance

with IEC 529.

However, in particularly exposed applications

protection in the form of screening is recommended.

Protection

Tous les modules PVE possèdent le degré de protection IP67

conformément à la IEC 529. Dans les zones particulièrement

exposées, il est cependant conseillé de protéger le PVE à l’aide

d’un écran ou d’un dispositif similaire.

A

V310 399.B