10 © Küschall AG,Schweiz | 2012-07

Service manual

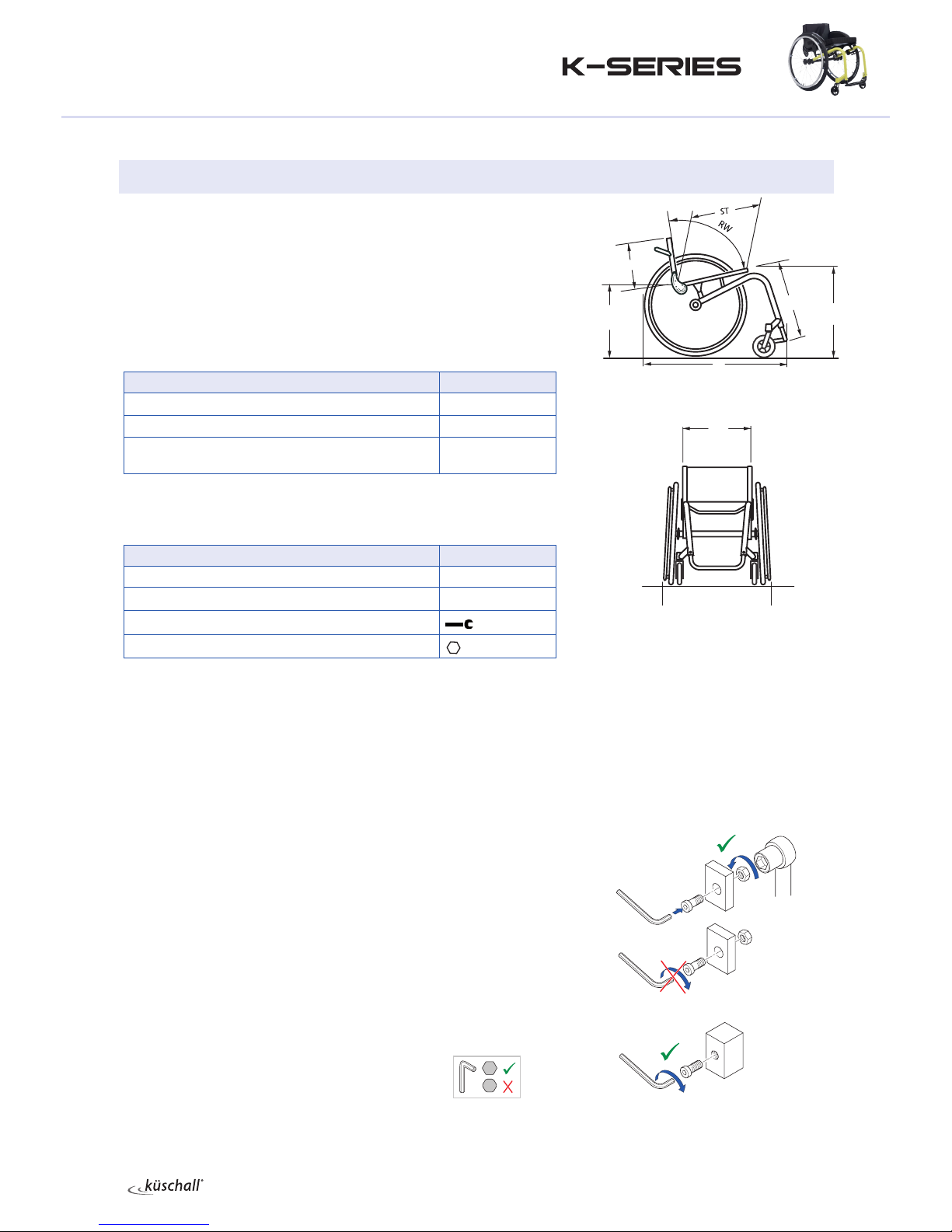

Seat

Tipping point adjustment

The tipping point of the wheelchair can be adjusted by changing the hori-

zontal position of the seat module.

Diculty: Tools: Ã4, 5

Remove the rear wheels, fold the backrest forward and place the

wheelchair on its back.

Loosen the screws , and .

Remove the screws and and slide the seat module forwards or

backwards.

Fix the seat module with the screws and and tighten the screws

, and again.

Carry out the same setting on both sides.

There are 3 possible positions for the rear bracket and 5 possible positions

for the front bracket.

iNote: ensure that the seat brace is as vertical as possible following

an adjustment.

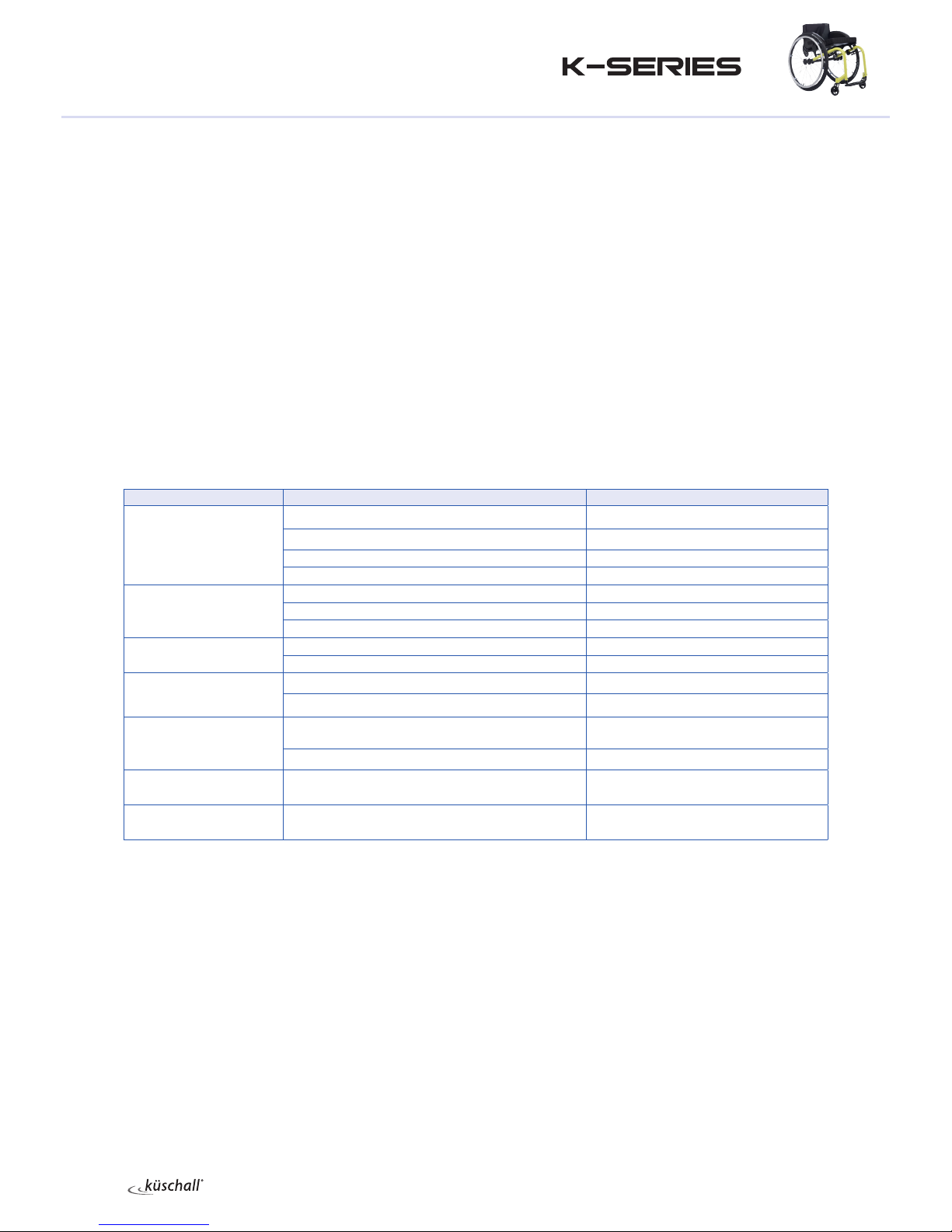

Suspension

A suspension can be tted for a SHh of between 380 and 460.

Fitting a suspension

Diculty: Tools: Ã4, 5

Remove the rear wheels, fold the backrest forward and place the

wheelchair on its back.

Remove the seat module by removing the brackets at the front and

the rear .

Removing the seat brace .

Fit the suspension housing to the frame. Here, slide the screw with

the washer through the suspension housing and place the lubricated

sleeve with the spacer elements on the screw. Slide the screw

through the frame into the axle holder stay and tighten it rmly.

Function check:

It must be possible to rotate the suspension housing , but it must not be

loose.

Insert the suspension seat strut from above into the suspension

housing . Slide the sleeve from below over the suspension seat

strut and position it at the desired seat height. Fix it using the screw

and the washer .

Carry out the same setting on both sides.

Lubricate the springs and insert them into the suspension

housing . Insert the screws into the suspension housing until they

protrude by 25 mm.

Fix the front and rear spring brackets to the seat module (screws a),

insert the lubricated rotating sleeves band x the seat module to the

frame (screws c) again.

Reattach the wheels and stand the wheelchair up again.

Check:

Check the front seat height. When tting the mudguard, ensure that it is at

least 4 mm from the wheel. Check the suspension function.

1

4

2

3

5

7

7

à7 Nm

à7 Nm

à7 Nm

à7 Nm

à13 Nm

1

2

3

4

4

6

7

9

8

6

12

12

13

13

5

10

11

à7 Nm

à4 Nm

aà7 Nm

cà7 Nm