3© Küschall AG, Switzerland | 2015-05

Service Manual

TABLE OF CONTENTS

GENERAL...................................................................................................................... 4

Introduction 4

Spare parts 4

Fastening with hexagon socket bolts 4

Torque 5

Checks 5

Identifying and repairing faults 5

FRAME............................................................................................................................6

Adjusting the frame 6

Changing the frame 6

SEAT ...............................................................................................................................7

Adjusting the seat height 7

Replacing the seat cover 7

BACKREST.................................................................................................................... 8

Adjusting the backrest height 8

Backrest angle 8

Tipping point of the wheelchair 8

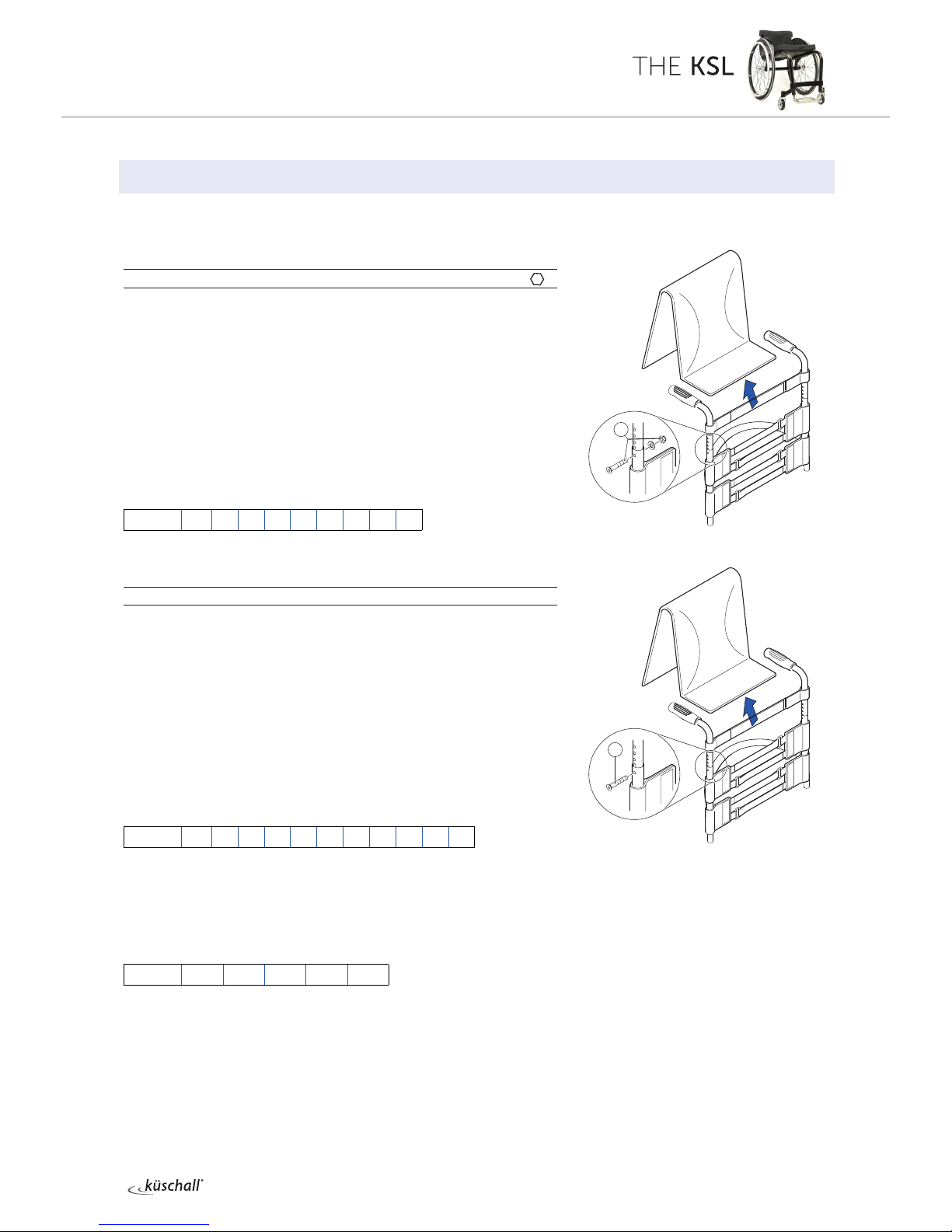

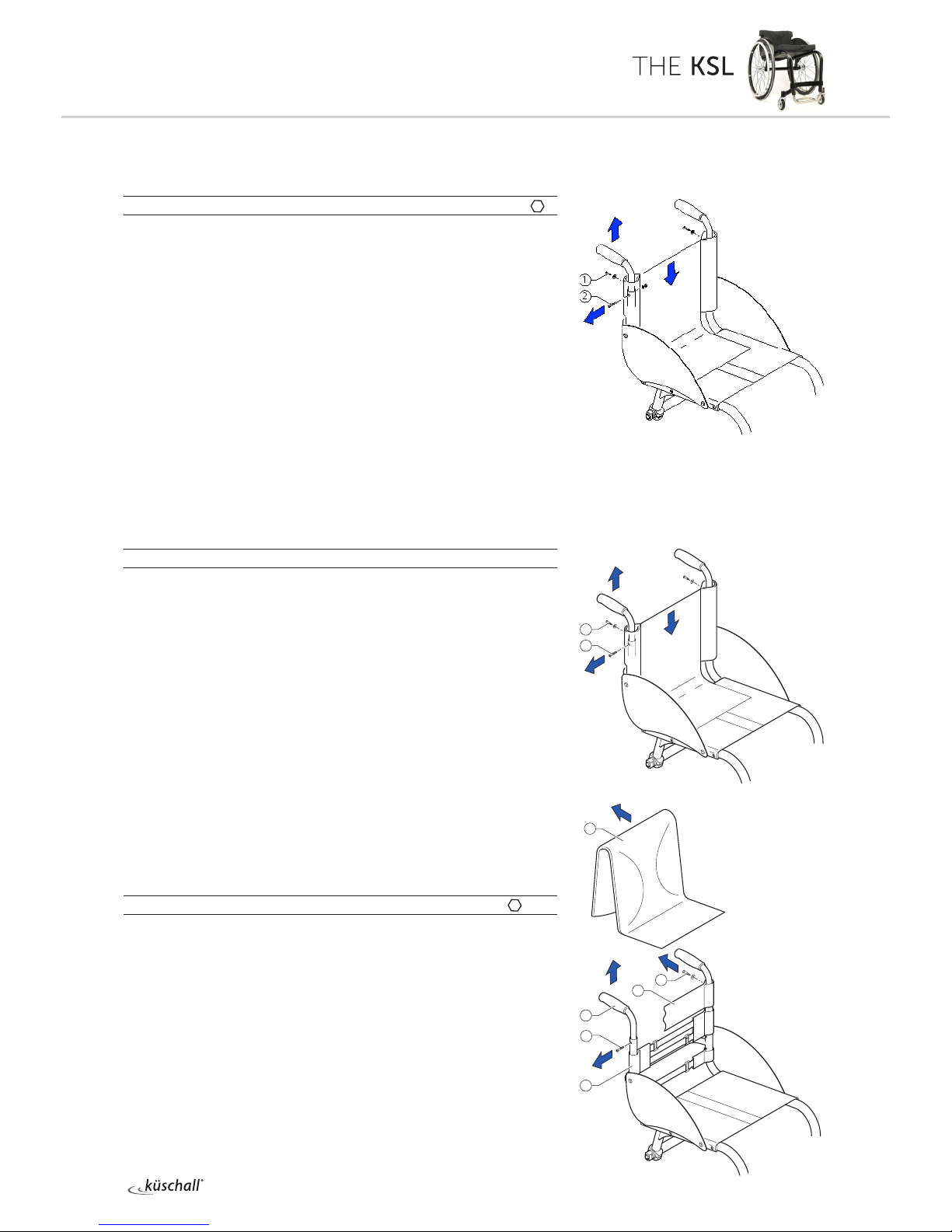

Replacing the Standard Light backrest cover 9

Replacing Velcro®tapes for adjustable backrests 9

Replacing push handles with Light cover 10

From serial number 13G08000785: Replacing push handles with Light cover10

Replacing push handles with adjustable backrest 10

Replacing foldable push handles 11

Foldable backrest, angle adjustable (optional) 12

FOOTRESTS ................................................................................................................13

Replacing the footrest 13

Adjusting the height of the footrest 13

Adjusting the angle of the footrest 13

SIDES............................................................................................................................14

Fitting the clothes guard 14

Fitting the mudguard 14

FRONT WHEELS.........................................................................................................15

Replacing the front wheel fork 15

Replacing the front wheel 15

Cleaning the front wheel bearings 15

REAR WHEELS ............................................................................................................16

Checking the tyre pressure 16

Checking the spoke tension 16

Checking that removable axles are seated correctly 16

Adjusting the removable axles 16

Replacing the rear wheels 17

Replacing the axle 17

Ensuring the rear wheels are parallel 17

Repairing or changing an inner tube 17

Fitting tubed tyres to carbon wheels 18

BRAKES ........................................................................................................................19

Fitting / adjusting the parking brake 19

OPTIONS & ACCESSORIES...................................................................................... 20

Fitting an antitipper 20