Page | 2

Contents:

Page:

General information and description: 1-4

RD kit parts and assembling 4-10

Preparing records 10-11

Preparing bat 11-13

Record cleaning 13

Record drying &wiping 13-14

Notes 15

General introduction:

Ultrasonic cleaning is used in industry for cleaning t e most precise and delicate parts suc as bearings for

t e aerospace industry or gold and silver jewellery. Ultrasonic ig frequency waves ( 40 kHz ) are

transmitted t roug water creating a process called cavitation. T is creates microscopically small bubbles

between t e surface of t e submerged parts and any small particles on surfaces, suc as dirt. T ese bubbles

burst and pus t e dirt away from surfaces. W en cleaning metal or plastic t e process must be optimised to

avoid damage to surfaces. To do t is it is necessary to control power, temperature and t e time of t e

cleaning process.

T is is ow all dirt in t e grooves of records, even in new pressings is removed. Sonic results are beyond

expectations!

To bring t e ultrasonic cleaning process to every record collector we decided to make t e RD kit's

( rotating and drying kit) purc ase price as low as possible, t us enabling t e customer to purc ase t e

ultrasonic cleaner bat locally (using our guidlines).

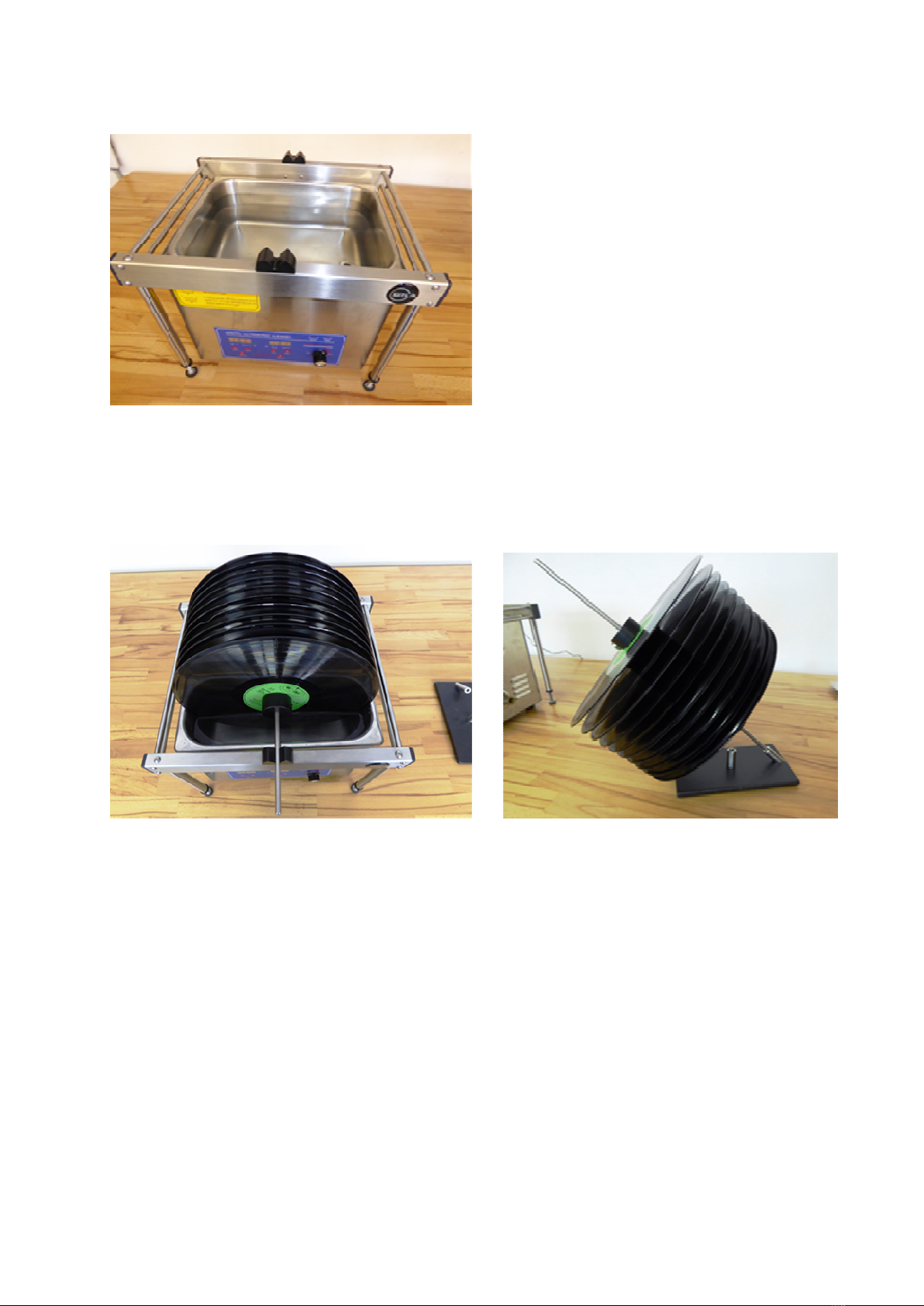

The Rotating and Drying record rack kit ( RD kit) will allow you to submerge records in t e ultrasonic

cleaning bat and position t em in a suitable drying position. For 45 EP look Notes on page 15.

It will allow you to clean 10 LPs in one our by t e ultrasonic process, giving you t e cleanest records

ever, free of static c arge.

Brief description of the ultrasonic cleaning process:

Records are positioned on t e spindle wit spacers on t e stand and t en submerged into t e ultrasonic

cleaner warm bat for a limited time. T e liquid is distilled water wit a few drops of isoproply alco ol

and wetting agent added. T e spindle rotates wit t e records, powered by a small motor w ile dipped into

t e liquid just below t e record labels. T e records rotate wit 0.4-0.6 rpm ( less t en one revolution per

minute).

If by any c ance t e record label gets wet no arm is done.

After ultrasonic cleaning t e spindle wit records is lifted out and positioned on t e stand to air dry. W en

dry, any particles on t e record surface are brus ed wit a carbon fibre brus ( records ave no static

electrical c arge ) and t e records are inserted if you wis into new sleeves.

Description of RD kit: (kit does not include ultrasonic cleaner bat )

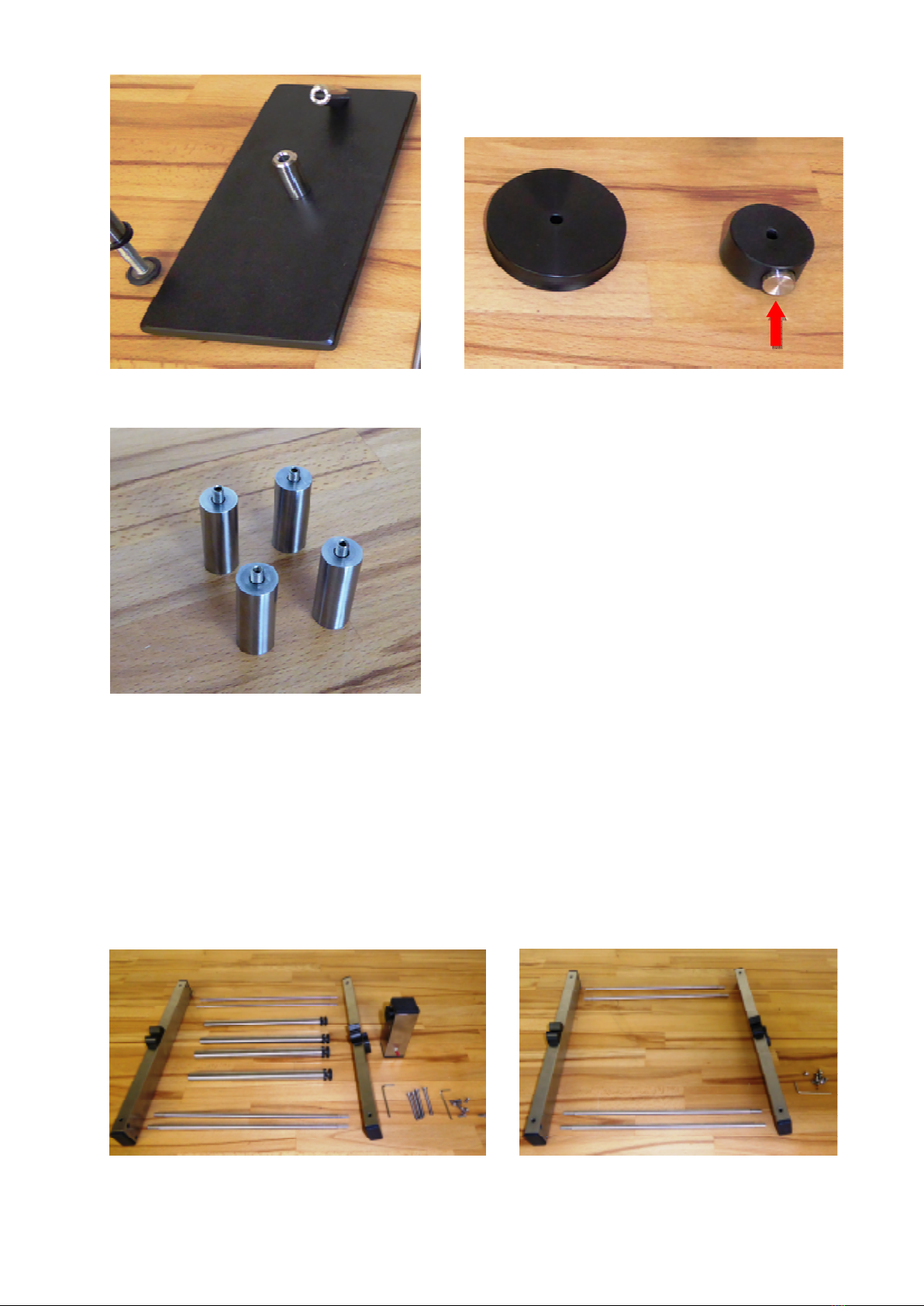

T e RD kit compromises frame wit motor , supporting legs, spindle for olding records, record spacers, a

clamp for fixing records on t e spindle and a stand for drying records. In t e kit small starter bottles of

isoproply alco ol and wetting agent are also included as well as a carbon fibre cleaning brus and DC

power supply for motor. Kit assembly requires only 10-15 minutes and a meduim size P ilips screwdriver.