IMPORTANT: PLEASE READ THROUGH THE ENTIRE

INSTRUCTION MANUAL BEFORE BUILD

ING

THE OUTLAW

RAMPA

GE

PRO

.

We want your experience of

bu

ilding th

is

mode

l to be a

su

ccess.

So

before

you r

emo

ve

any

parts

from the

ir

pac

kages and begin assembly:

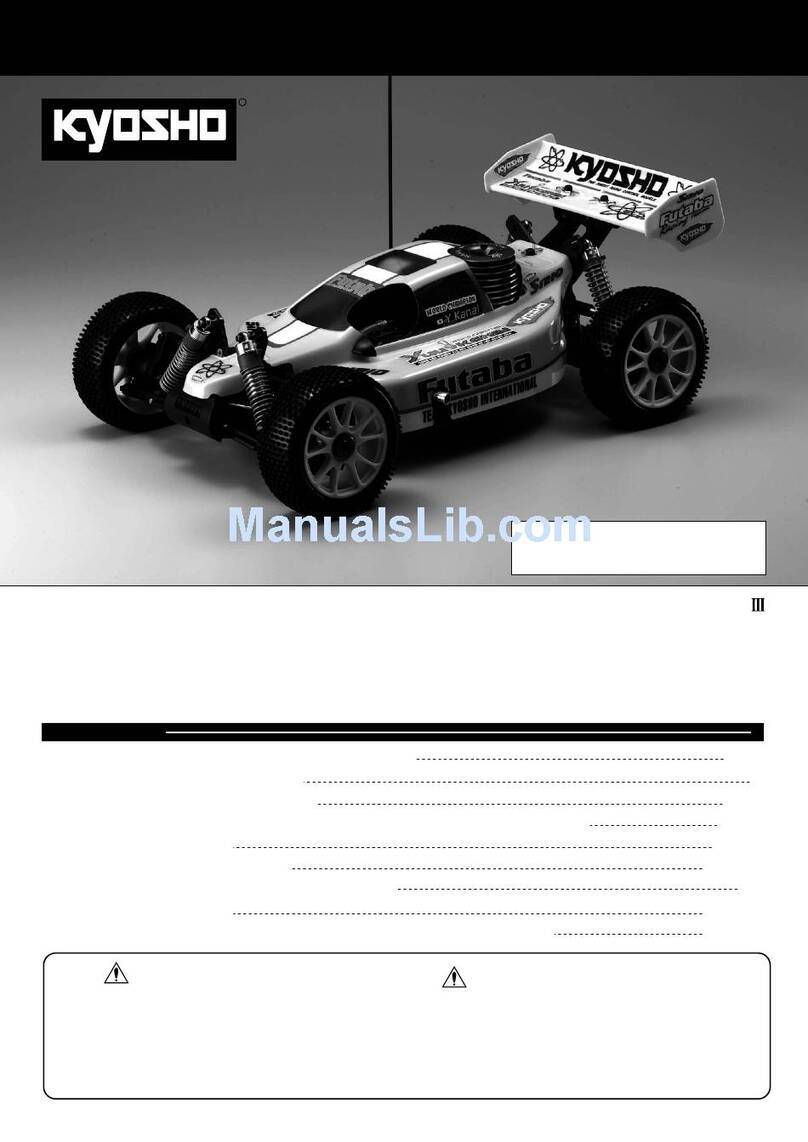

• Read through the entire manual carefully to make

sure

that you are thoroughlyacquainted withthe model.

• This instruction manual

is

for both the Outlaw Rampage

Pro Sport and Team Trucks. Differences in assembly

or

partswill be

not

ed as: (Team Tr

uck

Only).

• If for any reason you think this model may not

be

for you,

return

It

Immediate

ly

. Please N

ote

: Your hobby

dealer

cannot accept a m

ode

l kit f

or

return after assembly has

begun.

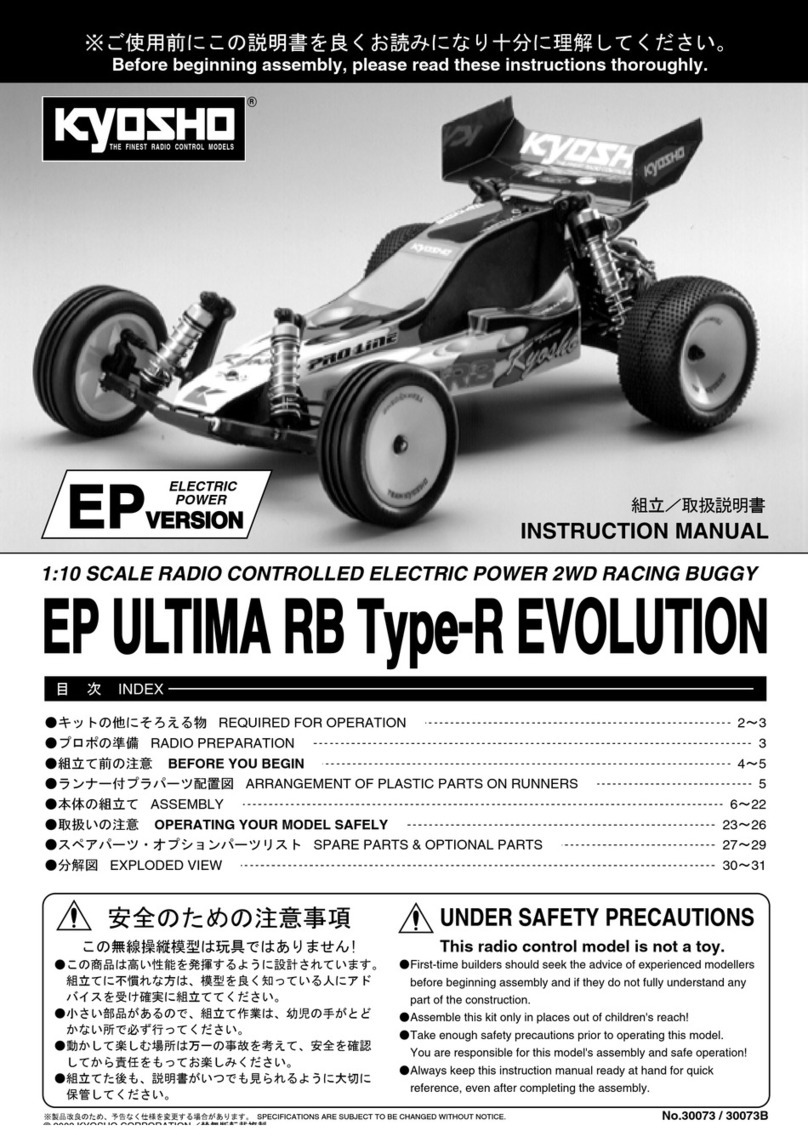

• The KyoshoOutlaw Rampage Pro

is

a sophisticated, high

per1ormance,

gas

powered off-road truck. Gas powered

RIC

trucl<s

are nomore diffiCult to build and operate than

electric

RIC

truc

ks

.

They

do

require

a

few

different

building

procedures

than

electrics.

If

you

follow

the

directions closely, the Kyosho Outlaw Rampage Pro will

provide many years

of

competitive RIC truck racing.

Key

Number~art

Name\

Quantity

U

sed

I

(§)

" @

Dri:'washer

(t I

Note

: Some parts are Identified with a key number@ .

The

'E'

stands f

or

parts tree

'E'.

The 4

is

the part number

on the tree.

METRIC SCREW IDENTIFICATION

All nuts

and

bolts used throughout this kit

are

metric size.

Therefore, some

of

the notations

may

not

be

familiar to

you.

An

M3 nut

is

a 3 millimeter (3mm) nut. An M3 x 14

screw

is

3mm

in diameter

and

14mm long. Some round

parts may

be

la

beled as an 'M3 Washer" {a washerwith a

3mm lns

1de

diameter)

or

an '

M4

x 8 Bushing" (a

bus~ing

with

a

4m

m i

ns

i

de

d

iame

ter

and

an

8mm

outs1de

diameter). A few different types of screws are used

In

th

e

construction

of

your model. Here are some examples and

how they will be

in

dicated In the instructions.

On

page 22

Inch and millimeter rulers are provided.

M3x14

Sc

'rew

Bushing

M3

Washer

~

A self tapping (SIT) screw has a coarse lhread

and

is

used

to

thread

in

to

plastic

..

86

c

areful

not

to

tight

en

th

e

scre

w

too

much

. l his

may

strip

t

ho

pla

stic.

This Kyosho instruction manual

uses

a

cross

reference

'=--

system

to

helpyou locate all

of

the bagged parts.

DO

NO

T

~

A

cap

scrowIs usodwllcretwo piecesolmolal

are

to

be

jo!nod. Tho

l>ox

head

allows a hex

wrench

to

be

usod,

Pfovldong

more

10<q0e

fa<

tightening.

open each bag and dump out the parts. Carefully remove

the header card from the bag and discard the staple. Slip

the headercard into the

babeg

ohr

tape T

itht?

the

11

ohuts

1

ide of0

thed

ft'luMI!MM

bag

so

that the bag num r s ows. IS

w1

ep you

1n

~-

Screws

haw

a

fono

thread

and

are used wilt! nutS

most of tn.

umo

.

Thoy

are

lorhigh slress joll1ts

where

strength

IS

required.

parts when you need them.

RE

MOVE THE

HEADER CARD SLIP CARD

INTO BAG

OR

TA

PE TO

OUTSIDE

On page 27·31 of this instruction manual, you will find a

complete list of replacement andoptional parts.

If

you need

to replace a part. consult this guide for the manufacturer's

stock number for the items needed. In the left margin

of

each page of instructions you will find a directory

of

small

parts

that

will

be

used

In

each

step.

For

ease

of

identification, these parts are shown actual size, enabling

you

to

place the part directly

on

the picture to ensure you

have

se

lected the appropriate part.

2

Aal

head (FIH)

acrows

have a

fine

tf1read

and a

1apered

head.

This

allows tho

head

olthe

acrow

10

be

!lushwllh lhe pan h

Is

holding solllat lhe

acrow

head doos no1

C4tch

on

anything.

llJJ)

Set

Sc<ews

have a nex

head

that

requ

ires a

heX

wrench.

TheM

are

for

joining parts where the

head

o1

a SCtttW

may

intorf""'wilhotherparu.

IMPORTANT SCREW INFORMATION:

Do

not

use

excess

ive

force when tightening self·tapping

screws into plastic. Over tightening will cause the threaded

portion

of

the plastic to strip. It

is

recommended to stop

tighteni

ng

when some resistance Is

fe

lt as the head of

th

e

screw contacts the part. Avoid using power screwdrivers

when

assembling

your

k

it.

They

tend

to

over

tighten

screws.

Do

not use screw cement (thre

ad

lock compound)

on

self-tapping screws. The screw oement may damage

the plastic.

Use

screw

cement (thread

lo

ck

compound)

only

on

scre

ws

that are fastened witha

nut

or

threaded into

a metal

sur1ace

. Vibration from the engine will cause these

screws tovibrate loosewijhoutscrewcement .

CORRECT

INCORRECT

l:jtt\ittltii""J