Vehicle Super Probe

- 2 -

1. Important Safety Information

To prevent personal injury or damage to vehicles and/or the test tool, read this

instruction manual first and observe the following safety precautions at a minimum

whenever working on a vehicle:

Always perform automotive testing in

a safe environment.

Wear safety eye protection that

meets safety standards.

Keep clothing, hair, hands, tools, test

equipment, etc. away from all

moving or hot engine parts.

Operate the vehicle in a

well-ventilated work area: Exhaust

gases are poisonous.

Put blocks in front of the drive

wheels and never leave the vehicle

unattended while running tests.

Use extreme caution when working

around the ignition coil, distributor

cap, ignition wires and spark plugs.

These components create

hazardous voltages when the engine

is running.

Put the transmission in PARK ( for

automatic transmission) or

NEUTRAL (for manual transmission)

and make sure the parking brake is

engaged.

Keep a fire extinguisher suitable for

gasoline/chemical/ electrical fires

nearby.

Don’t connect or disconnect any test

equipment while the ignition is on or

the engine is running.

Keep the tool dry and clean. Use a

mild detergent on a clean cloth to

clean the outside of the test tool,

when necessary.

When the rocker switch in the tool is

depressed battery current/voltage is

conducted directly to the tip which

may cause sparks when contacting

ground or certain circuits. Therefore

the tool should NOT be used around

flammables such as gasoline or its

vapors. The spark of an energized

tool could ignite these vapors. Use

the same caution as you would when

using an arc welder.

Warning!

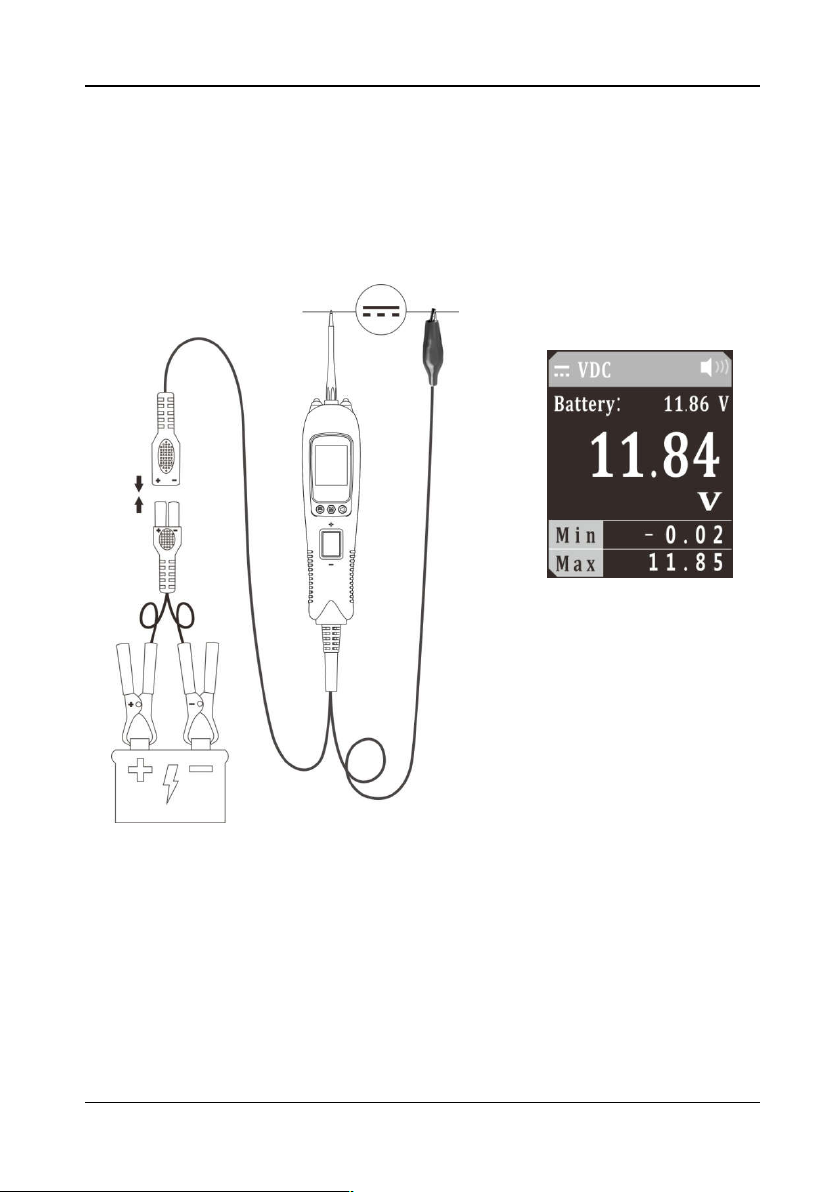

KM50 is ONLY for 12-24V vehicle battery electrical systems, and should NOT be

used to test 110/220V household electric appliances; otherwise, it will be damaged.

The LED and LCD pull no more than 100 milliamp of current, therefore when using

this device as a test light or multimeter, it is safe for computer and airbag.

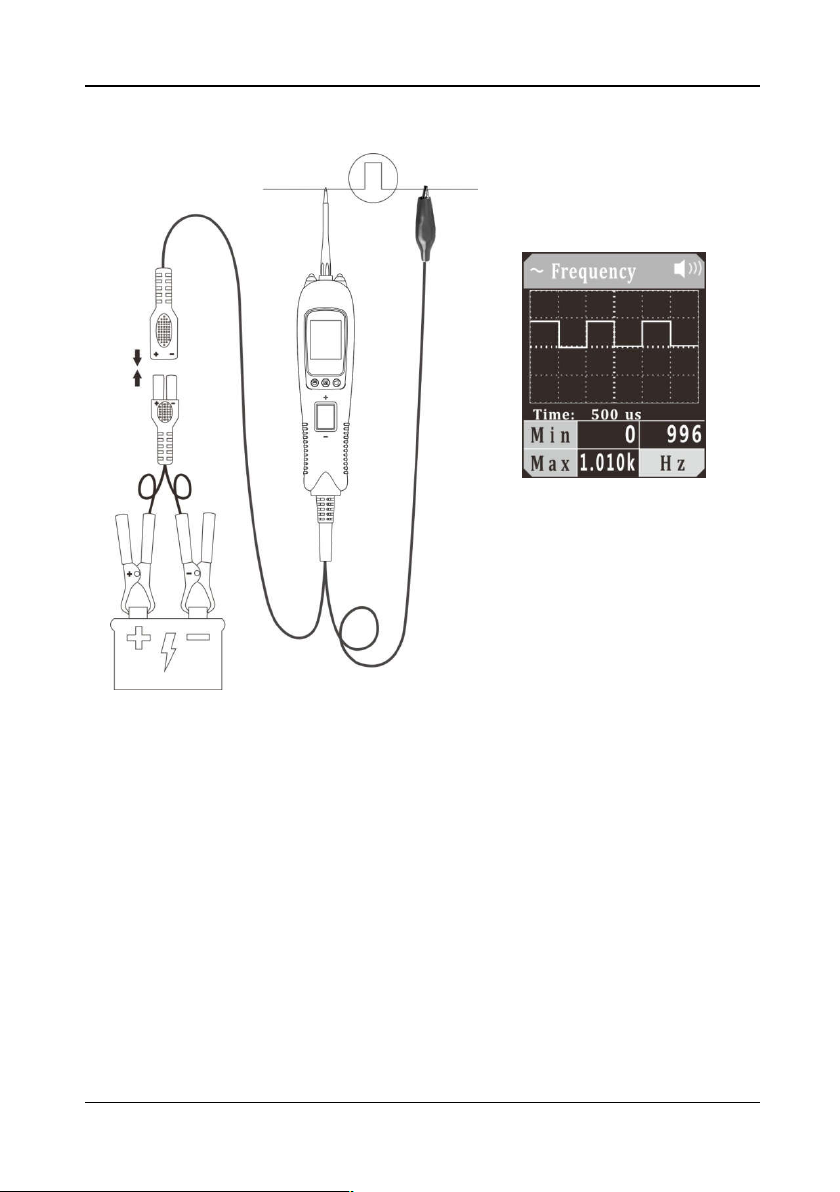

While performing component activation, please pay special attention: when the

instrument is powered on, if the rocker switch is pressed forward or rearward,

it means that all the battery current is being introduced from the positive or

negative pole through the probe. Please strictly follow the instructions to avoid

damage to the vehicle’s electrical component.