User Manual Profinet-IO - Gateway

Profinet-Gateway 716457_100_HB_EN.docx 3

Content

1 General Information ..................................................................... 5

1.1 Symbol Description .............................................................................................. 5

1.2 Copyright .............................................................................................................. 5

1.3 Disclaim of Liability .............................................................................................. 5

1.4 Safety ................................................................................................................... 5

1.4.1 Content of Manual .......................................................................................................... 5

1.4.2 Intended Use ................................................................................................................. 6

1.4.3 Operating Employee ...................................................................................................... 6

1.4.4 Maintenance .................................................................................................................. 6

1.4.5 Decommissioning and Deposal ...................................................................................... 6

2 Gateway – Profinet, 716457 ......................................................... 7

2.1 General Information ............................................................................................. 7

2.1.1 Explanation .................................................................................................................... 7

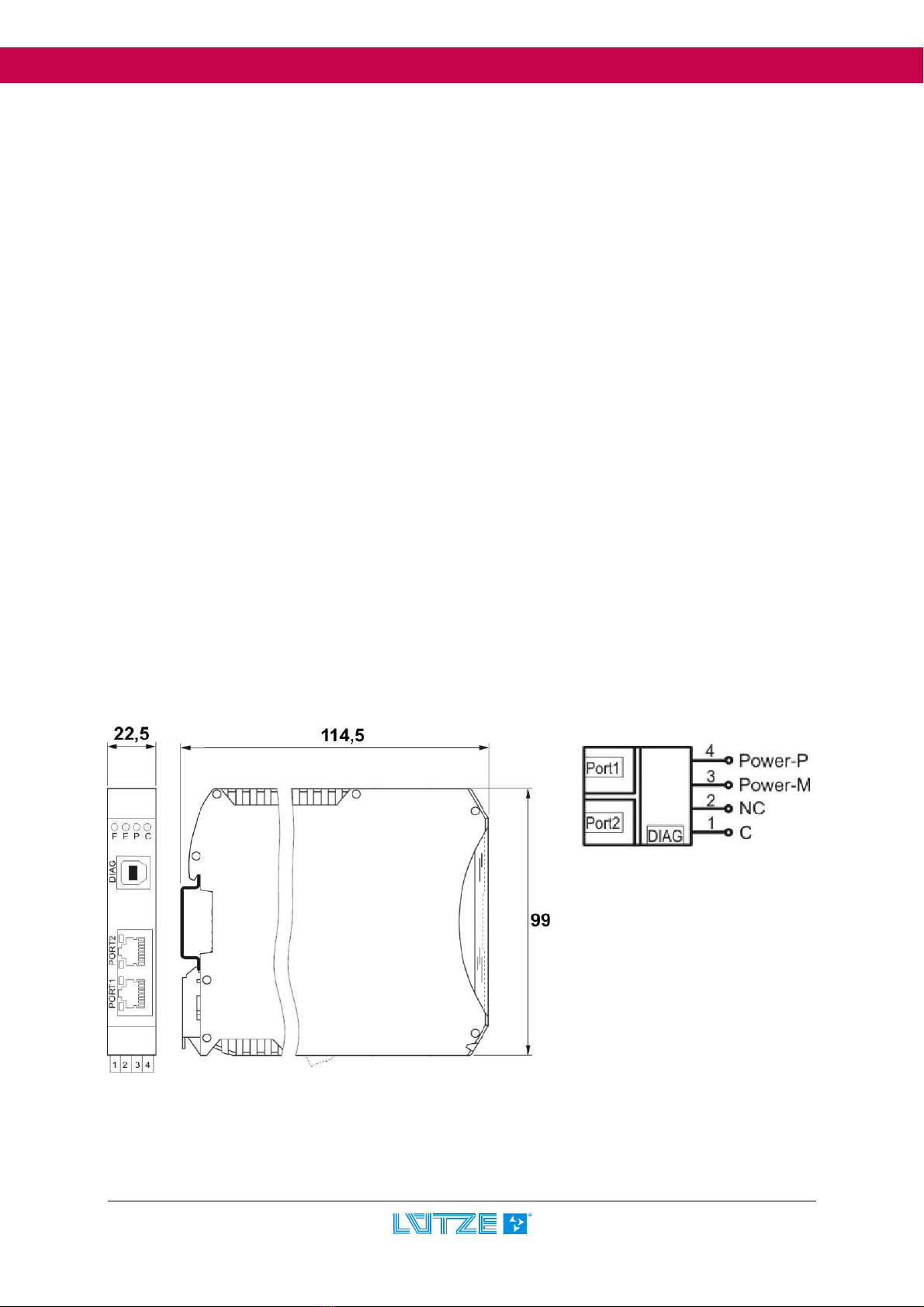

2.1.2 Dimensions and Connections ......................................................................................... 7

2.1.3 Function and Displays .................................................................................................... 8

2.1.4 Topology and Structure .................................................................................................. 8

2.1.5 LOCCbus - Interface ...................................................................................................... 9

2.1.6 Operation system and driver .......................................................................................... 9

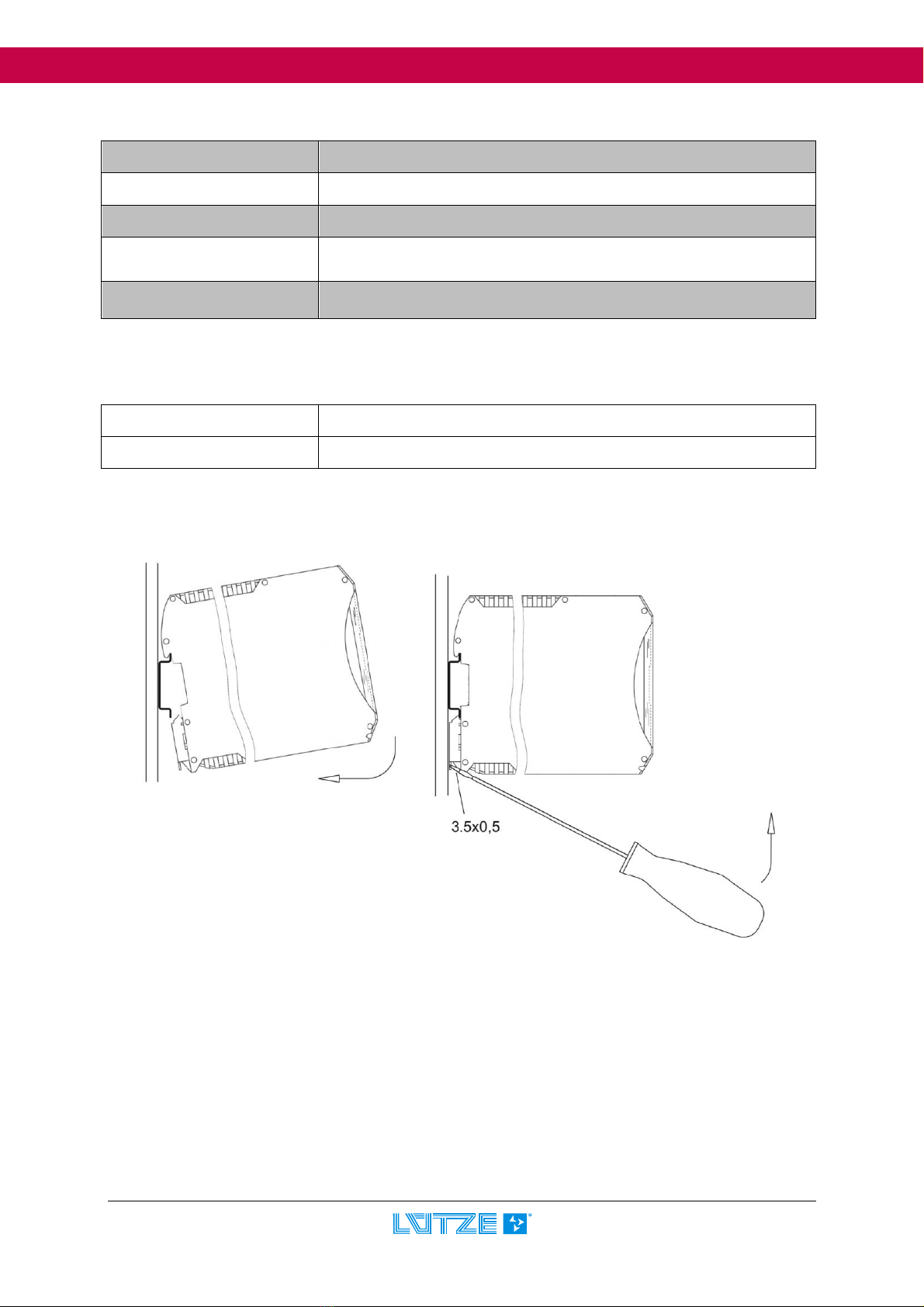

2.1.7 Mounting ........................................................................................................................ 9

2.1.8 Installation ................................................................ Fehler! Textmarke nicht definiert.

2.2 Installation .......................................................................................................... 10

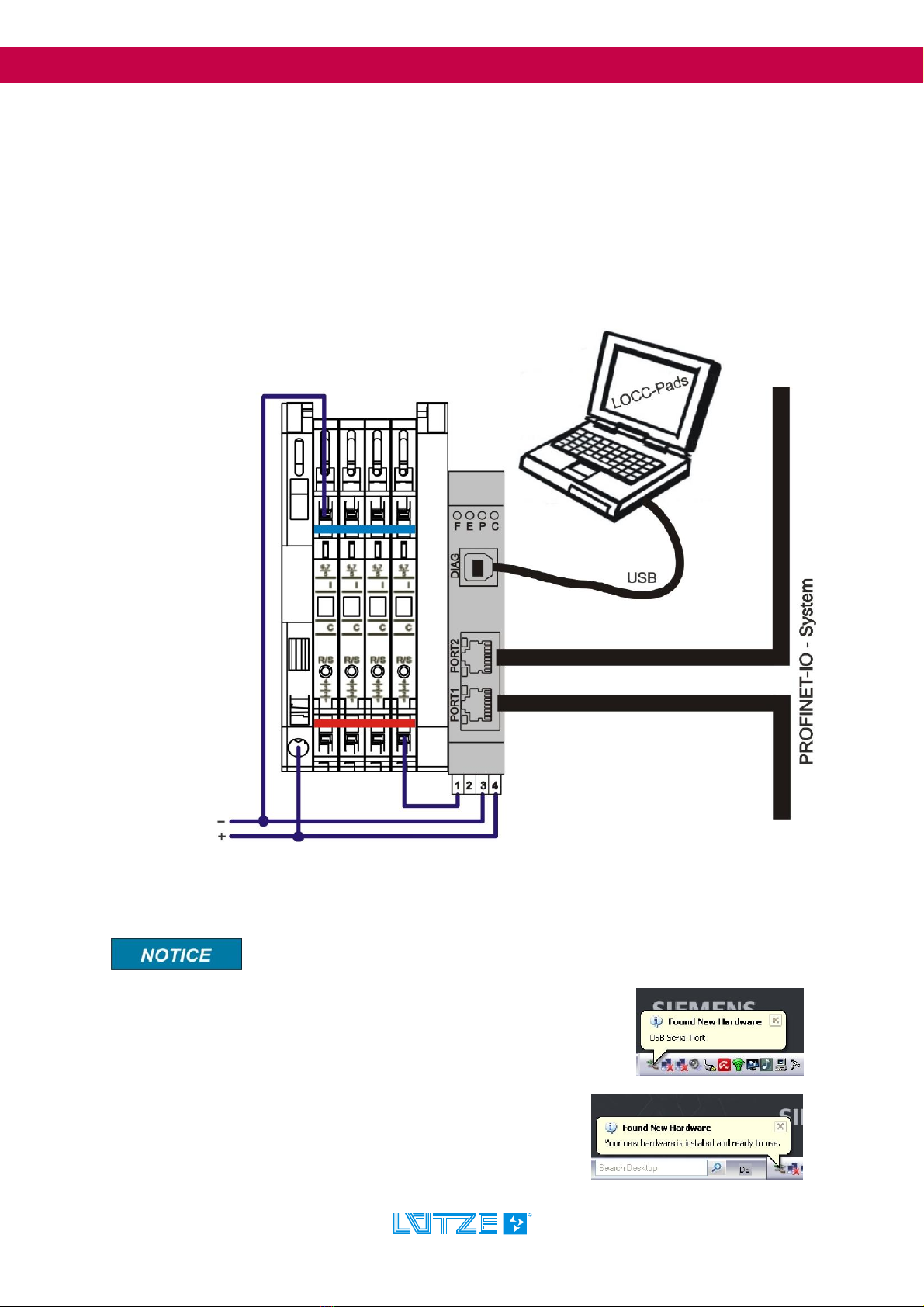

2.2.1 Stracture in principle .................................................................................................... 10

2.2.2 Connection to USB....................................................................................................... 10

2.3 Communication via USB .................................................................................... 11

2.4 Communication via Profinet-IO ......................................................................... 11

2.4.1 Terms and Definitions .................................................................................................. 11

2.4.2 GSDML - Files ............................................................................................................. 12

2.4.3 Profinet-IO Interface ..................................................................................................... 12

2.4.4 Function Range............................................................................................................ 13

2.4.5 Profinet-IO read request (overview of instruction) ......................................................... 13

2.4.6 Configuration in step7 .................................................................................................. 14

2.4.7 Device Access Point (DAP) .......................................................................................... 15

2.4.8 Adjustment of LOCC-Box ............................................................................................. 15

2.4.9 Process Image ............................................................................................................. 15

2.4.9.1 Input-byte ............................................................................................................ 16

2.4.9.2 Output-byte.......................................................................................................... 16

2.4.10 Optional I&M – Services ........................................................................................... 16

2.4.11 Example for the used instructions ............................................................................. 17

2.4.11.1 Module type (2000h) ........................................................................................... 17

2.4.11.2 Module status (2010h) ........................................................................................ 17

2.4.11.3 Module configuration (2011h) ............................................................................. 17

2.4.11.4 Output voltage (2100h) ....................................................................................... 18

2.4.11.5 Input voltage (2101h) .......................................................................................... 18

2.4.11.6 Current Measurement (2104h) ............................................................................ 18

2.4.11.7 Characteristic adjustment (210Ah) ...................................................................... 19

2.4.11.8 Software Version (2200h) ................................................................................... 19