SET-UP:

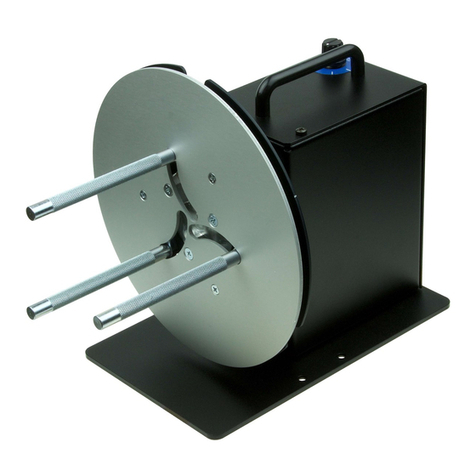

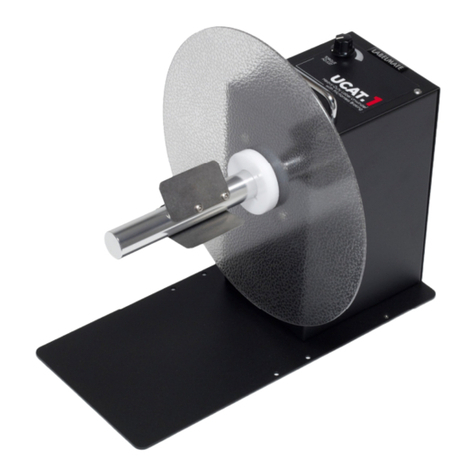

1. Using the supplied Allen Wrench, loosen the set screw and remo e the

Shaft (with metal Vanes) from the UCAT-1 Motor Shaft.

2. Locate the Label Flange Plate that has a white hub with Allen Screw.

Slide the Hub of the Flange Plate onto the hollow end of the Shaft

Extension. The plastic Flange disk Hub face should be flush with the

end of the Shaft. Tighten the Allen screw in the Hub until it is snug.

Note that the Flange plate can be mo ed out next to the Vanes that

hold the 3 inch core if ery narrow labels are to be unwound.

3. Slide the Shaft and Flange Assembly back onto the UCAT-1 Motor

Shaft allowing for clearance to the UCAT-1 Chassis and Motor Screws.

Tighten the Allen screw to secure the Shaft and Flange Assembly until

it is snug.

4. Set the unit in place near the label entrance path to the printer or

LABELMATE Label Slitter depending on the job to be run.

CAUTION: AVOID ACCIDENTS. THE UCAT-1 BY ITSEL WEIGHS

APPROXIMATELY 20 POUNDS (9 KG), SO CHOOSE ONLY A STURDY

SUR ACE ON WHICH TO SET THE UCAT-1.

The unit is now ready for use.

LABEL UNWINDING OR PRINTING:

The UCAT-1 is bi-directional and can unwind labels in either direction.

1. Slide the roll of labels to be unwound onto the Shaft of the UCAT-1 and

all the way up against the Flange Plate.

2. Thread the labels into the printer as required.

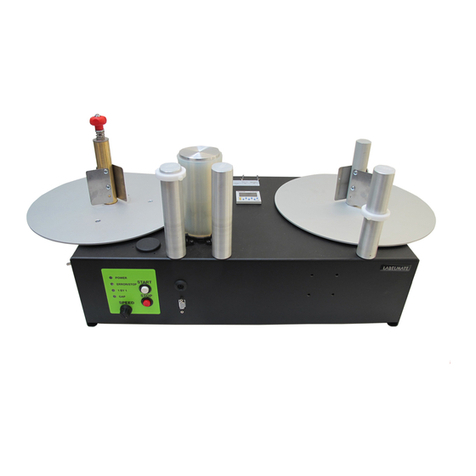

3. The “BRAKING” Control Knob adjusts the amount of “Frictionless

Braking”™ that will be applied to the label roll being unwound.

LABELMATE’s “Frictionless Braking”™ is speed proportional. This

means that for large label rolls, you will want the “BRAKING” Control

Knob turned to a higher setting to pro ide braking for the slowly turning

WARNING

This product is for indoor use only.

Not for use in wet locations.

Unplug unit before removing waste material or

performing any cleaning or maintenance services.

roll. For small rolls, you can use a lower braking force setting as the

roll will be turning faster.

4. Begin the printing or slitting operation and adjust the “BRAKING”

Control to pro ide the least braking that will adequately tension the

label roll.

LABEL UNWINDING OR LABEL SLITTING:

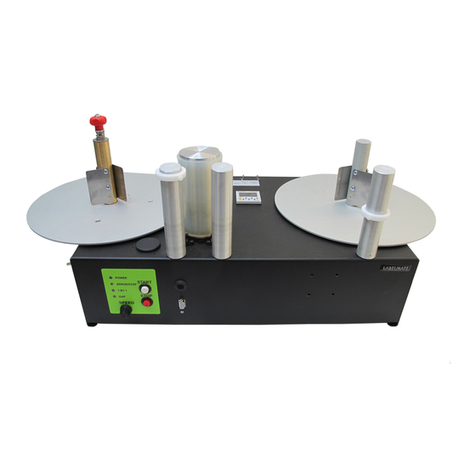

The UCAT-1 Label Rewinder is ideal as part of a setup to slit labels. If

small labels are printed se eral “up” (across) and then slit to their desired

width, you realize much greater effecti e print speed and you also achie e

much greater print head and ribbon efficiency.

LABELMATE offers three Label Slitters that can be used with the UCAT-1.

The Non-powered Slitters Models S-100 and S-200 use the power of the

CAT-2-CHUCK Rewinder to pull the labels through the slitting blades.

Slitting can take place either “in-line” directly after exiting the printer, or

“off-line” where a roll of printed labels is unwound from a LABELMATE

UCAT-1 Label Unwinder.

The Powered Model S-100-SP Slitter can be used with the UCAT-1 and a

CAT-2-CHUCK Rewinder in an off-line Slitter setup. Because it is a

constant-speed Slitter, the S-100-SP is not suitable for in-line slitting at the

output of a printer.

MAINTENANCE:

The UCAT-1 requires no maintenance.