12A Sunset Way, Henderson, NV 89014 USA

(702) 435-8535 FAX (702) 435-8536

Toll-Free (877) 833-7149 in USA!

w w w . l a b e l m a t e u s a . c o m

Product Limited Warranty

Labelmate USA warrants to the original end-user customer that Labelmate USA products will be free from

defects in materials and workmanship for the duration described herein below. Labelmate USA’s Limited

Warranty covers only those defects that arise as a result of normal use of the products and does not cover

any other problems, including those that arise as a result of: (i) improper maintenance or modification; (ii)

parts or supplies not provided or supported by Labelmate USA; (iii) operation outside the products’

specifications; or (iv) unauthorized repair, modification or misuse. Use of any unauthorized accessory or

attachment will void coverage.

The Warranty period for all products commences the date of shipment from Labelmate USA and accrues to

the original end-user customer. Warranty coverage is non-transferable and terminates immediately upon

rental, resale or any other change in ownership. Original purchase documentation should be retained for

Warranty coverage verification.

In the event Labelmate USA substantiates, during the applicable Warranty period, a defect in any product

which is covered by Labelmate USA’s Warranty, Labelmate USA shall repair or replace the product, at

Labelmate USA’s option. Labelmate USA retains sole discretion to determine whether or not a product is

defective. In no event shall Labelmate USA have any obligation to repair or replace until the customer

returns the defective product to Labelmate USA. The customer assumes any and all responsibility and

liability associated with transportation of products for service under this Warranty.

In the event your product requires service or you have questions regarding Warranty coverage, please call

toll-free (877) 833-7149 inside the United States, or +1 (702) 435-8535 outside the United States.

LABELMATE MAKES NO OTHER WARRANTY OF ANY KIND, WHETHER EXPRESS OR IMPLIED

WARRANTIES OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY QUALITY, AND/OR

FITNESS FOR A PARTICULAR PURPOSE. NO OTHER PERSON, AGENT, DEALER OR RESELLER IS

AUTHORIZED TO GIVE ANY WARRANTIES ON BEHALF OF LABELMATE. ANY OBLIGATION TO

WARRANTY OTHER THAN THAT SPECIFICALLY ADDRESSED HEREIN IS EXPRESSLY DISCLAIMED.

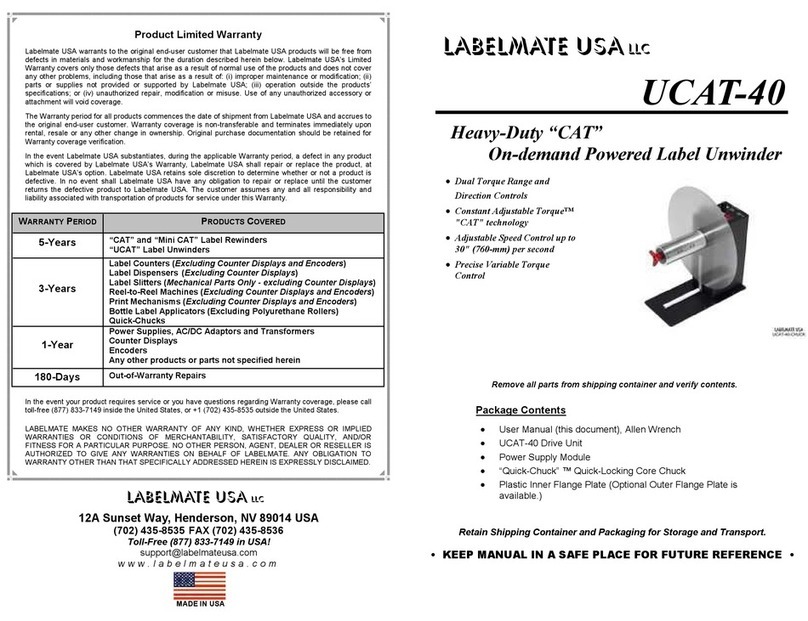

WARRANTY PERIOD PRODUCTS COVERED

5-Years “CAT” and “Mini CAT” Label Rewinders

“UCAT” Label Unwinders

3-Years

Label Counters (Excluding Counter Displays and Encoders)

Label Dispensers (Excluding Counter Displays)

Label Slitters (Mechanical Parts Only - excluding Counter Displays)

Reel-to-Reel Machines (Excluding Counter Displays and Encoders)

Print Mechanisms (Excluding Counter Displays and Encoders)

Label Applicators (Excluding Polyurethane Rollers)

Quick-Chucks

1-Year

Power Supplies, AC/DC Adaptors and Transformers

Counter Displays

Encoders

Any other products or parts not specified herein

180-Days Out-of-Warranty Repairs

MADE IN USA

BOXMATE-610 & 612

Automatic Label Applicator

for Labeling Square & Rectangular Items

Retain the Shipping Container and Packaging for Storage and Transport.

• KEEP MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE •

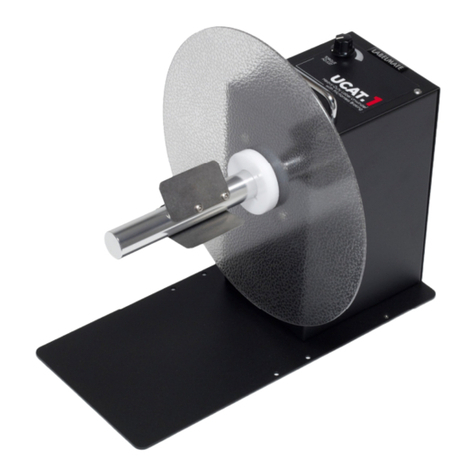

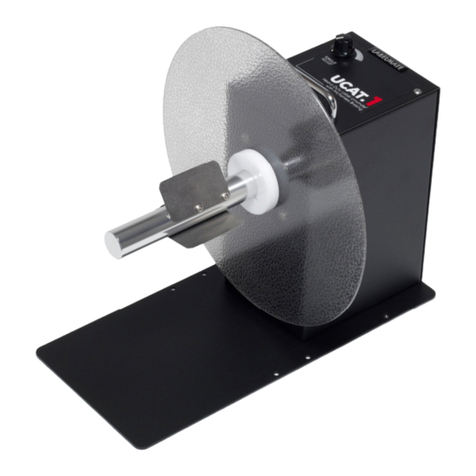

Remove all parts from shipping container and verify contents.

Package Contents

User Manual (this document)

BOXMATE-600 Series Label Applicator

Guide Flanges for Supply Roll (x2)

Extension Plates for Hold-down Roller (x2)

Core Adaptors (x2)

Allen Keys (x3)