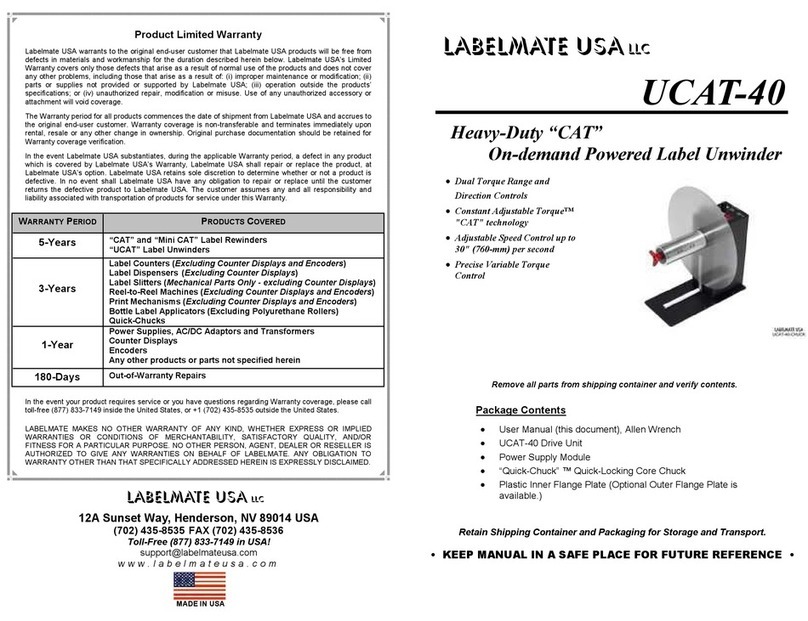

IMPORTANT INFORMATION:

•This product is a label unwinder. It is only to be used to unwind labels of the

recommended dimensions and weight in an indoor, dry environment.

•The machine is to be used on a flat surface, if the surface is not flat, it is to

be fixed using the holes in the base plate.

•The ambient light of the working area needs to be sufficient to avoid any risk.

•The unwinder can be used in ambient temperatures of +2°C to 40°C.

SET-UP:

(if you have the ACH Adjustable Core Holder option Skip to step 4).

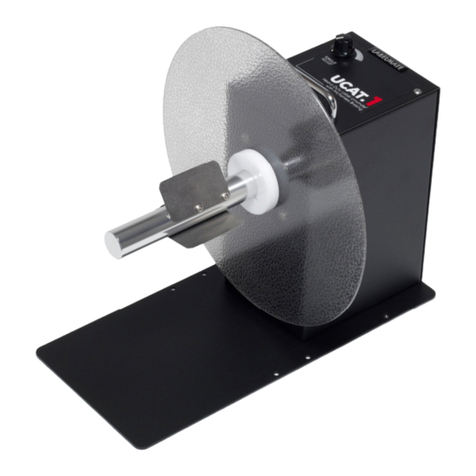

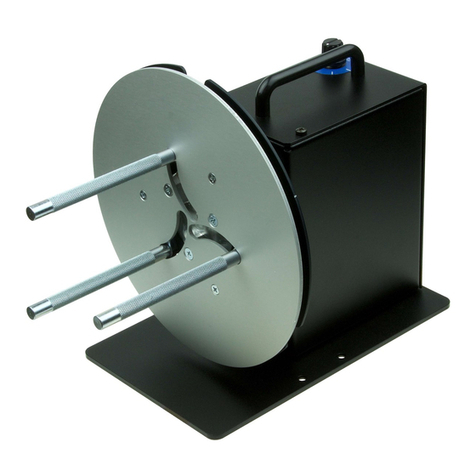

1. STANDARD AND 10": Identify the inner Label Flange Plate. Slide the

Flange Plate onto the hollow end of the Rewind Shaft. For maximum width,

the Flange face should be flush with the end of the Shaft. Tighten the screw

in the Hub until it is snug. Not too tight.

2. CHUCK: Mount the inner Flange onto the Quick-Chuck with two screws

provided.

3. Slide the Shaft and Flange Assembly onto the UCAT-1 Motor Shaft allowing

for clearance to the UCAT-1 Chassis and Motor Screws. Tighten the Allen

Screw onto the flat part of the Motor Shaft until it is tight.

4. ACH: Slide the Hub of the ACH over the motor Shaft of the CAT-2. Position

the Hub so there is a gap between the ACH Hub and the Rewinder Drive

Unit case. Tighten the Allen Screw onto the flat part of the Motor Shaft until it

is tight.

5. Set the UCAT-1 in place near the label entrance path to the printer or

LABELMATE Label Slitter depending on the job to be run.

6. CAUTION: AVOID ACCIDENTS. THE UCAT-1 WEIGHS OVER 9KG, SO

CHOOSE ONLY A STURDY SURFACE ON WHICH TO SET THE UNIT.

LABEL UNWINDING FOR PRINTING:

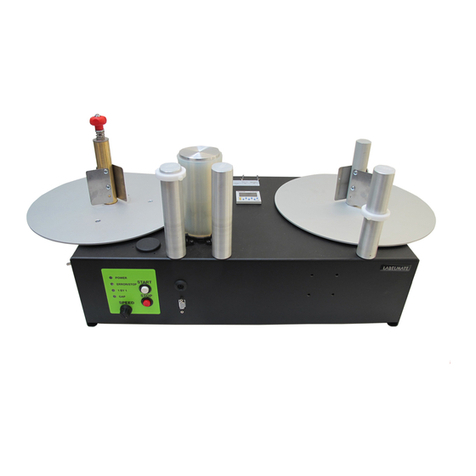

The UCAT-1 is bi-directional. It can unwind labels in either direction.

1. Slide the roll of labels to be unwound over the Quick-Chuck or Vanes on the

shaft until the core is against the inner Flange Plate. On the Quick-Chuck,

tighten the Lock Knob (for an ACH see the ACH user manual).

2. Thread the labels into the printer as required

3. The “BRAKING” Control Knob adjusts the amount of “Frictionless Braking”™

that will be applied to the label roll being unwound. LABELMATE’s

“Frictionless Braking”™ is speed proportional. This means that for large

label rolls, you will want the “BRAKING” Control Knob turned to a higher

setting to provide braking for the slowly turning roll. For small rolls, you can

use a lower braking force setting as the roll will be turning faster.

4. Begin the printing or slitting operation and adjust the “BRAKING” Control to

provide the least braking that will adequately tension the label roll.

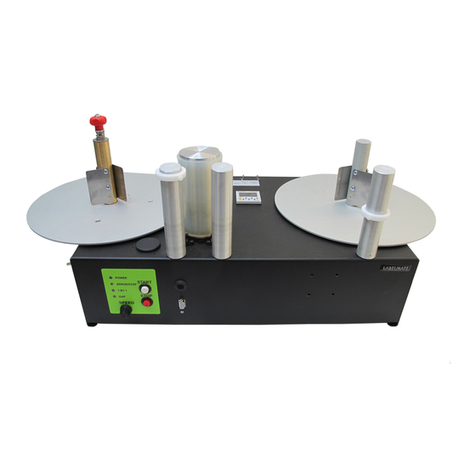

LABEL UNWINDING FOR LABEL SLITTING:

The UCAT-1 Label Rewinder is ideal as part of a setup to slit labels. If small

labels are printed several “up” (across) and then slit to their desired width, you

realize much greater effective print speed and you also achieve much greater

print head and ribbon efficiency. LABELMATE offers three Label Slitters (Models

S-100, S-200 and S-100-SP) that can be used with the UCAT-1. Slitting can take

place either “in-line” (except with the S-100-SP) directly after exiting the printer,

or “off-line” where a roll of printed labels is unwound from a LABELMATE UCAT-

1 Label Unwinder.

5.