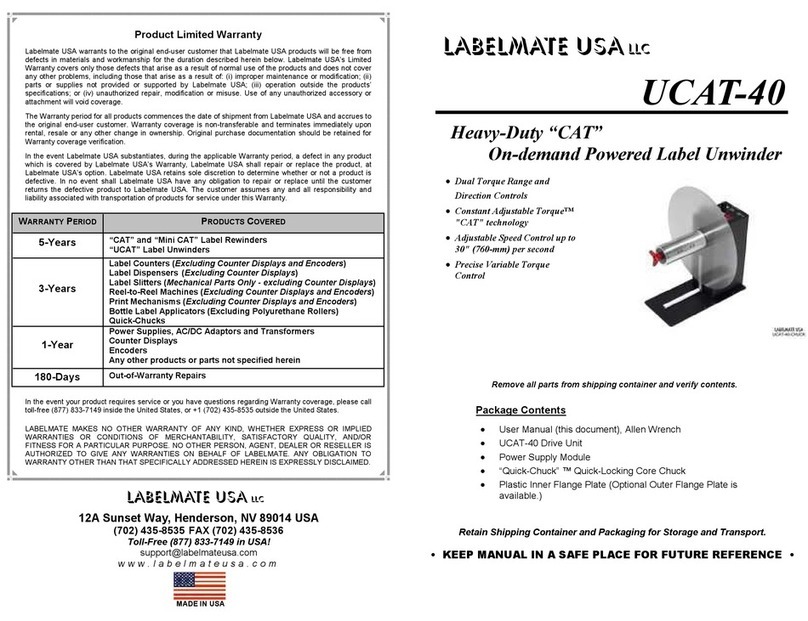

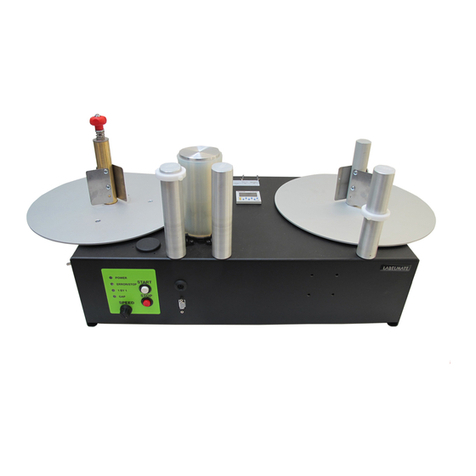

SPECIFICATIONS:

Max. Label Roll Weight: 6Kg.

Max. Label Roll Size: 300mm diameter

Speed: Adjustable from 0 to max. 40 cm/sec or 61cm/sec.

Accuracy: +/- 5%.

The speed specification applies for a machine used in normal

office room temperatures.

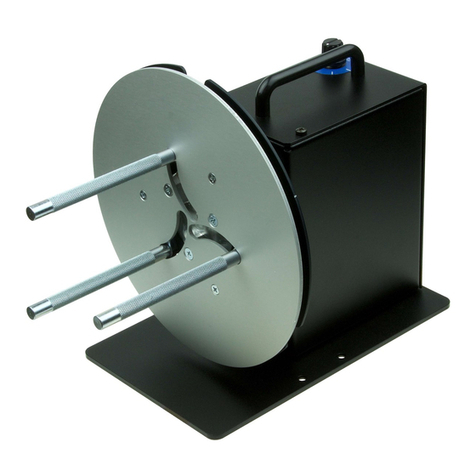

Take-up reel: The take-up torque is adjustable and it is possible to select

wind-in or wind-out

Power Supply: 230V –50-60 Hz. AC Input. 150 watts. (110V optional)

SET-UP:

1. Connect the unit to a 230V mains using the supplied power cord. The ON/OFF switch

is located near the power inlet. The machine is protected by a fast-blow fuse of 3.15A

and a spare fuse is provided in the fuse holder.

2. The speed of the machine is set at maximum, when shipped.

3. The machine is fitted with 2 photo-switches positioned left and right from the speed

control roller. The left-side photo-switch is used for the “out of paper” function. The

right-side photo-switch detects the labels and is used by the internal counter; the

signal is also available on the interface connector.

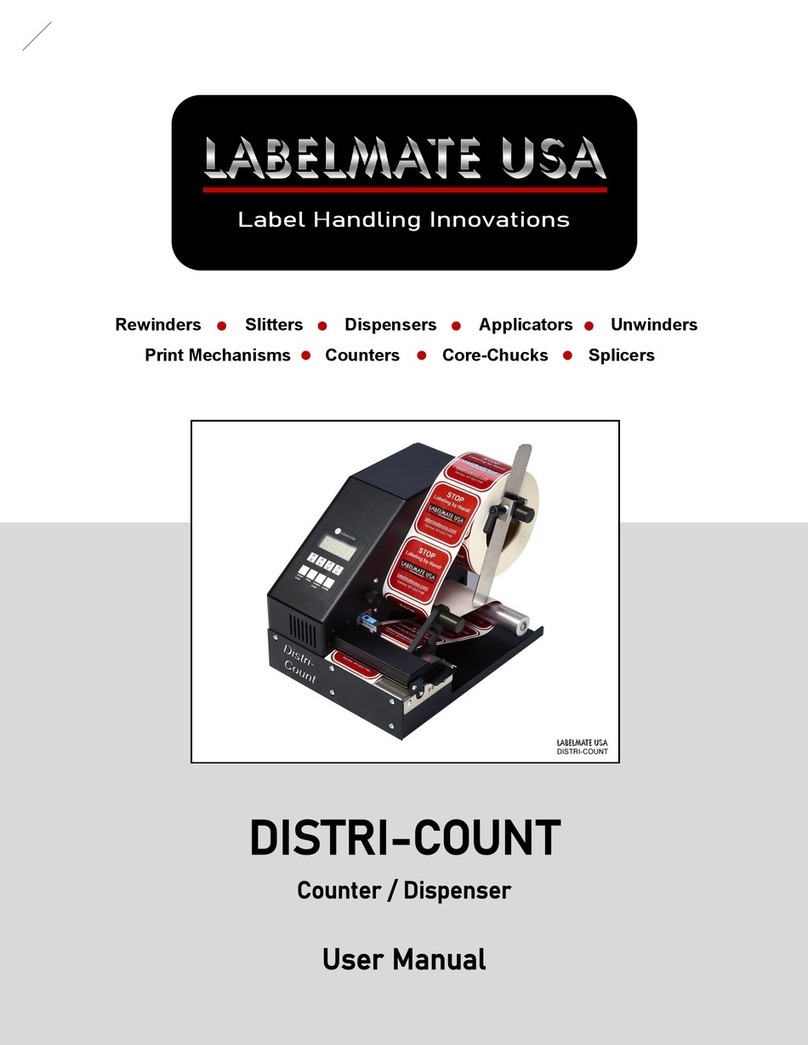

FRONT CONTROL PANEL:

POWER (GREEN):Indicates power is applied to the unit. The

ON-OFF Power Switch is on the rear of the Unit.

ERROR / STOP (RED):Indicates that either the unit is in

STOP mode or one of the three Error Conditions has occurred:

1. The unit is Out Of Paper.

2. The counter has reached the Pre-Set Value.

3. There is a Print Head Error condition. e.g.: No more ink

(condition valid only if the Print Head supplies this signal).

INK LOW (RED): Indicates that the Print Head has sent an Ink-Low Signal.

GAP (YELLOW):Flashes when Unit is running, indicating proper detection of the Gap

between successive Labels.

START BUTTON (WHITE):Start printing, if no Error Condition is present.

STOP BUTTON (RED):Holding down this button will stop the machine when the next gap

passes in front of the photocell.

SPEED CONTROL: Varies the speed from zero to maximum.

LEFT SIDE CONTROL PANEL:

TEST: Green LED

ADJUST: Potentiometer.

RESET: Only if optional counter is fitted. The

new left-side control panel has three items. The

toggle switch (reset) is a momentary closing switch

that has the same function as the reset button on

the counter, but is more convenient for the operator.

ADJUSTING THE LABEL DETECTOR PHOTOCELL (RIGHT PHTOCELL):

The label detector photocell has been adjusted at the factory (potentiometer fully CCW)

and requires no adjustment for a large variety of labels. However, some specific labels

(very transparent or relatively opaque backing paper) might require adjustment of the

photocell.

Load a roll of labels on the machine, and position the backing paper in front of the

photocell. Make sure that the labels are tensioned when doing the test. The LED should

light on. If not, rotate the potentiometer till LED goes on “green”. Now put a label in front

of the photocell, the LED should turn off.

CONTROLS & HEAD CONNECTOR ON FRONT OF THE UNIT:

Signals: ENC A and ENC B: Square wave 0 –15V.

Linear encoder resolution: 40 or 80

microns (depending on model).

Gap: Open collector (15V).

Start: Pulse 12V to 15V (The pulse

length should be shorther than the

time it takes to advance one label).

Busy: Output: 15V when motor is

running. 0V when stopped.