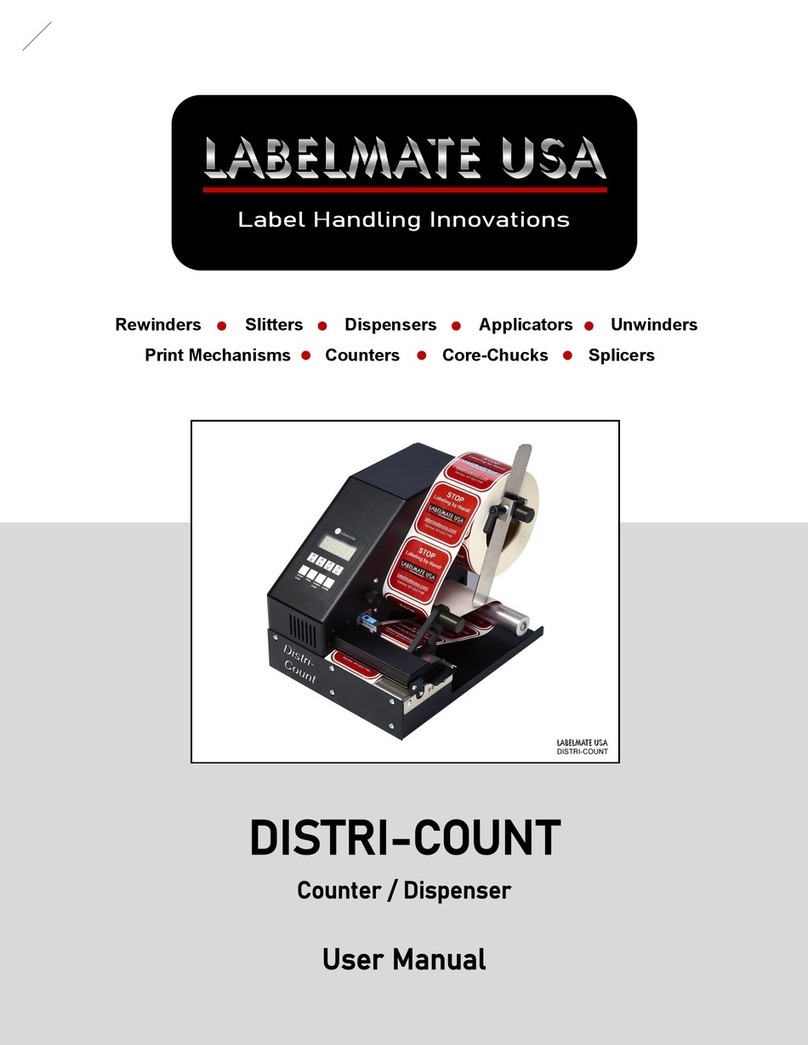

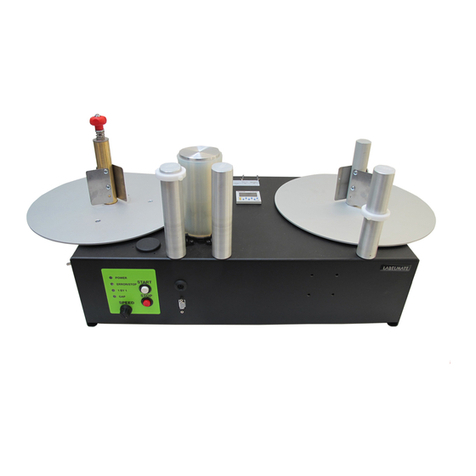

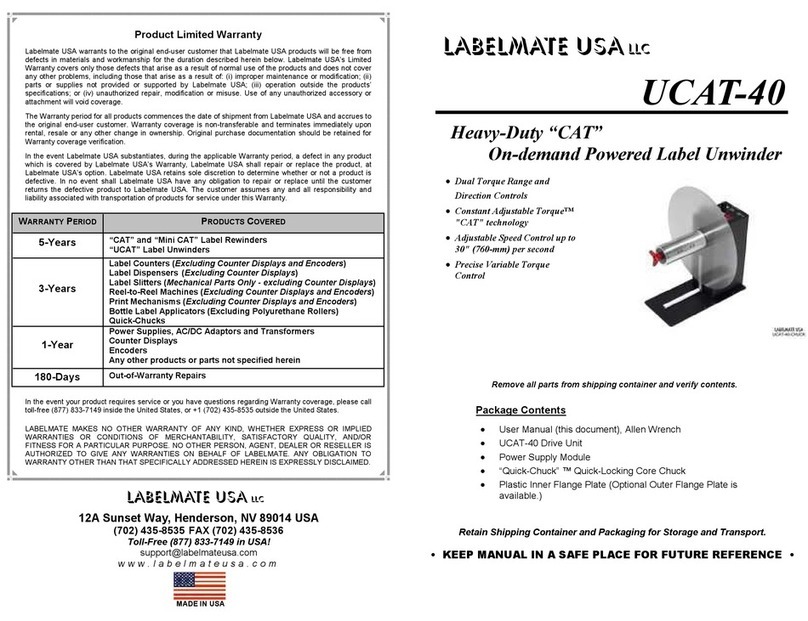

LABEL INFORMATION AND MOUNTING

Labels should be wound on 3” cores with the core extending all the way to

the edge of the roll. Any “label out” copy position is acceptable.

The copy position for printed labels is number 3 (recommended) or 4 (see

Diagram 1). This determines which way the label dispenses off of the roll

and also which direction you will put the bottle into the machine. Copy 3

allows the neck of a wine bottle to hang over the left side of the machine

as shown in the picture on the cover of this User Manual.

Labels must be die-cut with approximately 1/8” gap. Narrow labels will

work but the backing paper for them must be at least 1-1/2” inch width.

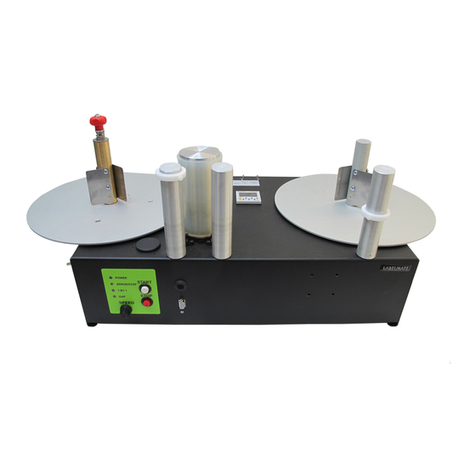

There are two 11” long, 1/16” aluminum roll guides and a tension spring

included with the machine. These guides should be placed on either side

of the roll of labels between the metal core inserts and the locking collar.

The notches on the end of the guide slide onto the chrome rod at the

bottom of the machine.

The Tension spring goes between the right roll guide and the locking collar

on the right side of the roll of labels as shown in diagram 2.

Note: The aluminum roller at the front of the machine is attached with a

screw and nut to the mounting blocks on either side of the roller. Save the

screws for securing the roller assembly. The nuts are installed for shipping

purposes only and can be discarded.

THREADING THE LABELS

~Please Refer to Diagram 3~

1. Pull locking assembly “E” forward until it swings freely.

2. With labels facing down, unroll about 2 feet (600 mm.) of the labels and

bring them under label drive roller “B”, which is located in the middle of the

machine. Thread the labels between the top and bottom dispensing ta-

bles “D” & “E” and then back towards the label roll. Make sure that the la-

bels are over the label sensor lever “C” located behind the front rubber

roller. If needed loosen the thumbscrews on either side of label roll and

slide the roll to the proper position then re-tighten the thumbscrews.

3. Thread the labels under the locking assembly “A” and over label drive

roller “B”.

4. Put slight tension on the labels by pulling them towards the back of the

machine and STRAIGHT over the roll of labels.

5. While keeping tension on the labels pivot the locking assembly “A”

towards the back of the machine until it “SNAPS” in place over label drive

roller. You may need to push hard, but it will “snap” when it is locked.

6. Power on machine. Tap the foot-switch until a label dispenses every time

you tap it. If labels continue to feed without stopping, or if a label only

partially feeds past the label sensor then stops, a label sensor adjustment

is needed.

LABEL SENSOR ADJUSTMENT

ONLY IF STEP 6 FAILS! SENSOR ADJUSTMENT DOES NOT AFFECT PLACEMENT!

7. SIDE TO SIDE adjustment only: Simply loosen thumbscrew and slide sen-

sor left/right to desired position, tighten thumbscrew. CONTINUE TO STEP

8!

8. While thumbscrew is tight, reach under front of machine and grasp label

sensor housing. Pull sensor housing towards the Feed Drive Roller until the

small metal lever “C” is away from dispensing table “D”, now carefully and

SLOWLY push housing towards dispensing table “D” until lever just makes

contact with dispensing table and then STOP! MAKE SURE NOT TO OVER

ADJUST. If you continue to adjust the sensor towards the dispensing table

“D” after it makes contact, (causing the sensor to Pre-Load) the machine will

continue to feed labels without stopping.

HORIZONTAL ADJUSTMENT

Adjusting horizontal placement of the labels on the object can be done 2

different ways:

1. You can simply adjust the bottle guide in the front to apply the label where

you need.

2. You can slide the labels side to side, but this may require a sensor

adjustment if the labels no longer are contacting the label sensor, then

refer to step 7.

DUAL LABEL OPTION - FRONT TO BACK SPACING ADJUSTMENT

If you purchased a BM-910P-2 or BM-1510P-2:

1. Flip (1-label 2-label) toggle switch to down position for two label application.

2. Measure the circumference of the bottle.

3. Measure the total length of both labels (include the gap between labels on

the roll)

4. Subtract the total label length from the circumference and divide by 2.

Example: If your circumference is 9.42” and your labels total 5” then

9.42” – 5” = 4.42” divided by 2 = 2.21 (set the display to 2.21). You may have to

make minor adjustments to achieve best results. The display reads from left to

right as follows: Inches, Tenths of an Inch, and Hundredths of an Inch

(hundredths of MMs, tenths of MMs, and MMs). Each position on the display has

its own button below it. The position will read from 0-9 and then back to 0.

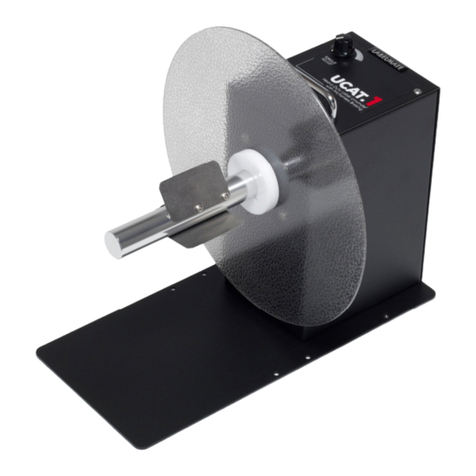

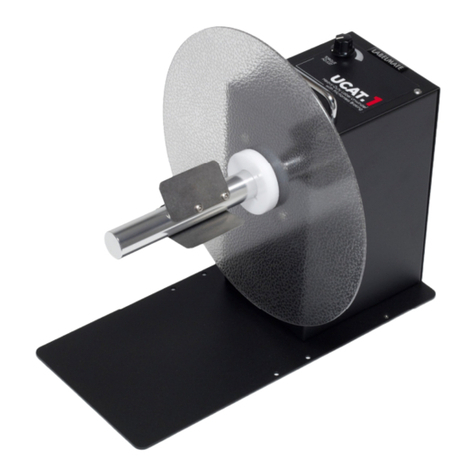

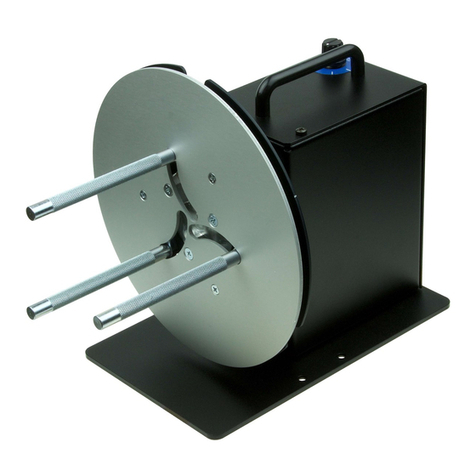

OPTIONAL WASTE REWINDER

If your machine has the optional “Waste Re-Winder” after following previous

steps, take the waste paper back and over the take up spool, put your spring clip

on (be sure not to push clip against frame).

LABEL INFORMATION AND MOUNTING

Labels should be wound on 3” cores with the core extending all the way to

the edge of the roll. Any “label out” copy position is acceptable.

The copy position for printed labels is number 3 (recommended) or 4 (see

Diagram 1). This determines which way the label dispenses off of the roll

and also which direction you will put the bottle into the machine. Copy 3

allows the neck of a wine bottle to hang over the left side of the machine

as shown in the picture on the cover of this User Manual.

Labels must be die-cut with approximately 1/8” gap. Narrow labels will

work but the backing paper for them must be at least 1-1/2” inch width.

There are two 11” long, 1/16” aluminum roll guides and a tension spring

included with the machine. These guides should be placed on either side

of the roll of labels between the metal core inserts and the locking collar.

The notches on the end of the guide slide onto the chrome rod at the

bottom of the machine.

The Tension spring goes between the right roll guide and the locking collar

on the right side of the roll of labels as shown in diagram 2.

Note: The aluminum roller at the front of the machine is attached with a

screw and nut to the mounting blocks on either side of the roller. Save the

screws for securing the roller assembly. The nuts are installed for shipping

purposes only and can be discarded.

THREADING THE LABELS

~Please Refer to Diagram 3~

1. Pull locking assembly “E” forward until it swings freely.

2. With labels facing down, unroll about 2 feet (600 mm.) of the labels and

bring them under label drive roller “B”, which is located in the middle of the

machine. Thread the labels between the top and bottom dispensing ta-

bles “D” & “E” and then back towards the label roll. Make sure that the la-

bels are over the label sensor lever “C” located behind the front rubber

roller. If needed loosen the thumbscrews on either side of label roll and

slide the roll to the proper position then re-tighten the thumbscrews.

3. Thread the labels under the locking assembly “A” and over label drive

roller “B”.

4. Put slight tension on the labels by pulling them towards the back of the

machine and STRAIGHT over the roll of labels.

5. While keeping tension on the labels pivot the locking assembly “A”

towards the back of the machine until it “SNAPS” in place over label drive

roller. You may need to push hard, but it will “snap” when it is locked.

6. Power on machine. Tap the foot-switch until a label dispenses every time

you tap it. If labels continue to feed without stopping, or if a label only

partially feeds past the label sensor then stops, a label sensor adjustment

is needed.

LABEL SENSOR ADJUSTMENT

ONLY IF STEP 6 FAILS! SENSOR ADJUSTMENT DOES NOT AFFECT PLACEMENT!

7. SIDE TO SIDE adjustment only: Simply loosen thumbscrew and slide sen-

sor left/right to desired position, tighten thumbscrew. CONTINUE TO STEP

8!

8. While thumbscrew is tight, reach under front of machine and grasp label

sensor housing. Pull sensor housing towards the Feed Drive Roller until the

small metal lever “C” is away from dispensing table “D”, now carefully and

SLOWLY push housing towards dispensing table “D” until lever just makes

contact with dispensing table and then STOP! MAKE SURE NOT TO OVER

ADJUST. If you continue to adjust the sensor towards the dispensing table

“D” after it makes contact, (causing the sensor to Pre-Load) the machine will

continue to feed labels without stopping.

HORIZONTAL ADJUSTMENT

Adjusting horizontal placement of the labels on the object can be done 2

different ways:

1. You can simply adjust the bottle guide in the front to apply the label where

you need.

2. You can slide the labels side to side, but this may require a sensor

adjustment if the labels no longer are contacting the label sensor, then

refer to step 7.

DUAL LABEL OPTION - FRONT TO BACK SPACING ADJUSTMENT

If you purchased a BM-910P-2 or BM-1510P-2:

1. Flip (1-label 2-label) toggle switch to down position for two label application.

2. Measure the circumference of the bottle.

3. Measure the total length of both labels (include the gap between labels on

the roll)

4. Subtract the total label length from the circumference and divide by 2.

Example: If your circumference is 9.42” and your labels total 5” then

9.42” – 5” = 4.42” divided by 2 = 2.21 (set the display to 2.21). You may have to

make minor adjustments to achieve best results. The display reads from left to

right as follows: Inches, Tenths of an Inch, and Hundredths of an Inch

(hundredths of MMs, tenths of MMs, and MMs). Each position on the display has

its own button below it. The position will read from 0-9 and then back to 0.

OPTIONAL WASTE REWINDER

If your machine has the optional “Waste Re-Winder” after following previous

steps, take the waste paper back and over the take up spool, put your spring clip

on (be sure not to push clip against frame).