UNICO 01.07.2019

English / Englisch

1

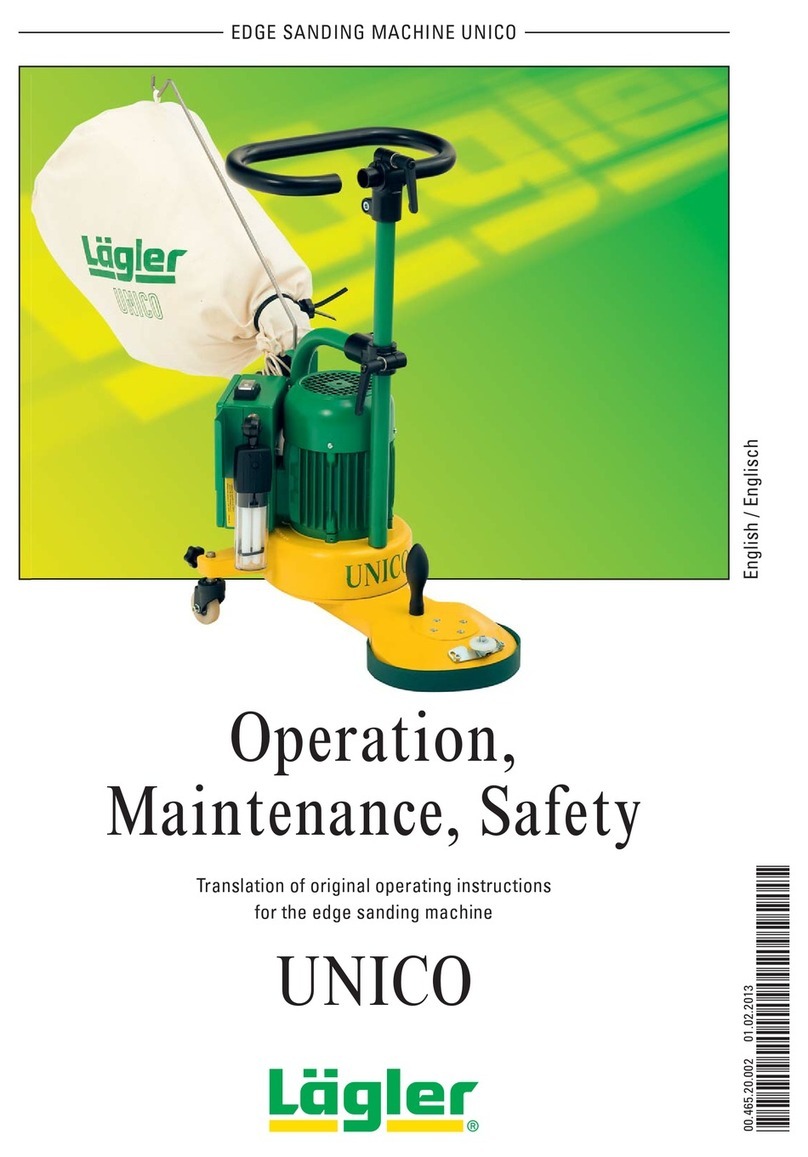

1.1 FEATURES OF THE MACHINE

In Figure 1 we have provided the UNICO with the designations of

the most important components. Please take a little time to become

with the machine.

1.2 DESCRIPTION OF THE MACHINE

The edge sanding machine UNICO works with a sanding disc wheel,

which is installed in an attachment. Three attachments in various

lengths can be supplied. The housing of the attachment covers the

actual working zone. A machine handle, which is used to guide the

machine when you are working on your knees, can be installed

depending on the length of the respective attachment. Velcro

sealing tape is used to seal off the working zone from the discharge

of dust. The resulting increased flow speed of the air upon entering

the working zone from outside guarantees constant good suction of

the sanding dust. Inside the attachment, there is a running V-belt,

which is driven via the V-belt pulley of the motor installed vertically

on the fan housing. The two guide rollers, which support the rear

of the machine, are also installed on the fan housing. In front, the

machine rests on the sanding abrasive (three-point support). The

fan housing is provided with two additional drilled holes into which

the machine handle can be screwed if and when required. On the

rear side of the fan housing, a rotating pipe bend fitted to a pipe

union conveys the sanding dust into the dust bag. The dust bag is

fastened to the pipe bend by means of a quick fastener.

The dust bag is suspended from the cable support by means of

a textile loop. This textile loop keeps the connection cable away

from the working zone and is inserted in the holder on the pipe

bend of the machine guiding system. This holder also includes

the Allen key, which is required to replace conventional sanding

discs. The pipe bend can be used to guide the machine when you

are working on your knees. An extension including a handlebar is

installed at the front end of the pipe end and can be used to guide

the machine when you are working in a stooped position or in an

upright position. The extension and the handlebar can be adjusted

as soon as the clamping lever has been opened.

The machine guiding system and the switch box are attached to

the motor. An ON/OFF switch including no-volt release as well as

the rotating and swiveling working light is fitted to the upper side

of the switch box.

Introduction

INTRODUCTION

You have purchased a high-quality product

from LÄGLER®. We wish you a great deal

of success with your UNICO. All LÄGLER®

products are subjected to a thorough

inspection before leaving the factory.

Read these operating instructions

completely before working with the

UNICO for the first time! These operating

instructions include important information

on occupational safety and will provide

you with answers to many questions

so that you can work with the machine

safely and without any problems. If you

cannot find a specific subject in these

operating instructions, please read

the LÄGLER®application technique

manual “Sanding of wooden floors”

(http://www.laegler.com) or contact our

service department, your retailer or your

importer.

5