tornos DECO 7e User manual

TORNOS SA

CH−2740 MOUTIER

http://www.tornos.ch

INSTALLATION

Printed in Switzerland Copyright E1999−2007

ΔATTENTION !

Before handling / operating the machine,

read first the SAFETY REGULATIONS !

DECO 7e / 10e

199222 − 0017

199224 − 0017

300440 en

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 3

TABLE OF CONTENTS

1. GENERALITIES 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 GENERAL INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Conformity to standards and directives 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 ADDRESSES 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 DIFFERENTIATION OF DEGREES OF RISK 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 IMPORTANT SAFETY INDICATIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. GENERAL 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 SAFETY MEASURES & DEVICES 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 STANDARD MACHINE DATA 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. UNPACKING − CLEANING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 UNPACKING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 CLEANING THE MACHINE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. LOCATION AND INSTALLATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 FLOOR PLANS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Floor Space of DECO 10e 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Floor Space with ROBOBAR SSF−107 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Floor Space with ROBOBAR SBF−216 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.4 Floor Space with Tryton 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 FLOOR LOCATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Floor Preparation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 4

4.3 PACKING AND HANDLING FOR REMOVALS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 ELECTRIC INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Installation Characteristics 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 ELECTRIC CONNECTION DECO 10E 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 Connecting TORNOS Autotransformer 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Connecting Non-TORNOS Autotransformer 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 CONNECTING BARFEEDER AND CHIP CONVEYOR 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 PNEUMATICS INSTALLATION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.1 Air Quality Specification 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 1.2 /1

1. GENERALITIES

1.1 GENERAL INFORMATION

This document is written based on the information available at the moment

of its publication.

TORNOS S.A. may not be held responsible, however, in case of errors or

omissions.

The original language of this document is French.

The information contained in this document is the property of TORNOS S.A.,

which is intended exclusively for internal customer usage, and may not be dis-

closed to or reproduced for third parties.

1.1.1 Conformity to standards and directives

The CE-marking i indicates that this product conforms with the

European standards of safety, health, environment and protection.

1.2 ADDRESSES

TORNOS S.A.

Rue Industrielle 1 1 1

CH−2740 MOUTIER / SUISSE

Tél. 032 / 494 44 44

Fax 032 / 494 49 03

TORNOS TECHNOLOGIES

IBERICA

Pol. Ind. El Congost

Avda. St Julia, 206 Nave 8

E−08400 GRANOLLERS

Tel. (34) 93 846 59 43

Fax (34) 93 849 66 00

TORNOS−TECHNOLOGIES

DEUTSCHLAND

Karlsruher Str. 38

D−75179 PFORZHEIM

Tel. 07231/ 910 70

Fax 07231/ 910 750

TORNOS TECHNOLOGIES

ITALIA SRL Via Einstein, 24

I−20090 ASSAGO / MI

Tel. 02 45 77 17 01

Fax 02 45 70 16 48

TORNOS TECHNOLOGIES

FRANCE

Boîte postale 330

ST−PIERRE EN FAUCIGNY

F74807 LA ROCHE

S / FORON CEDEX

Tél. 04 50 038 333

Fax 04 50 038 907

TORNOS TECHNOLOGIES

US CORPORATION

70 Pocono Road PO. Box 325

BROOKFIELD CT 06804 / USA

Tel. (203) 775−4319

Fax (203) 775−4281

TORNOS TECHNOLOGIES UK Ltd

Tornos House

Whitwick Business Park Coalville

Leicestershire

LE67 4JQ

Tel. 01530 513100

Fax 01 530 814212

TORNOS SHANGHAI

REPRESENTATIVE OFFICE

Tower B, Office 512−513

Far East International Plaza

No. 319 Xianxia Road

CN−SHANGHAI 200335

Tel. +86 21−62351235

Fax +86 21−62351938

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 1.4 /2

1.3 DIFFERENTIATION OF DEGREES OF RISK

These instructions indicate a number of safety measure symbols which

appear also on the machine and are intended to protect the user, his/her

effects and the environment from injuries and damage as applicable.

Below, you will find the safety symbols, their headings and definitions. Please,

read these first before you continue.

ΔDanger !

indicates a direct danger of death or serious injury.

ΔWarning !

indicates an object or action which may cause death or serious

injury.

ΔCaution !

indicates an object or action which may cause injury or serious

damage.

.Attention !

indicates incorrect actions or such that may cause damage.

⊗Prohibition !

indicates an action or operation prohibited because of evident or

alleged hazards.

⇒Info :

Gives information or comment related to safety.

Note :

Gives information unrelated to safety

1.4 IMPORTANT SAFETY INDICATIONS

ΔWarning !

Read the instruction before operating the machine.

Should the user disregard the instructions of this manual, TORNOS SA

declines any liability whatsoever.

.Attention !

Certain maintenance works are absolutely necessary to ensure good

operation of the machine. They are given in the MAINTENANCE

SCHEDULE on the machine

(or see Instructions: OPERATION-MAINTENANCE).

.Attention !

TORNOS SA disclaims all responsibility for any modifications carried

out by the customer to the machine, and to its related equipment and

software, without agreement ratified by TORNOS SA.

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 2.2 /1

2. GENERAL

2.1 SAFETY MEASURES & DEVICES

These are described in the Instructions 300480: SAFETY REGULATIONS

DECO 2000.

ΔWarning !

Failure to comply with the safety regulations may

cause serious accidents.

2.2 STANDARD MACHINE DATA

Feature Note Data

Length : 1550 mm

Width : 1000 mm

Height : 1800 mm

Weight : enclosure approx. 670 kg

DECO 0017 approx. 1500 kg

Specific load : DECO 0017

(per surface unit) 4.2 daN/cm2

⇒Note :

For more details, consult your operating instructions entitled :

OPERATION & MAINTENANCE.

⇒Note :

For more details, consult your operating instructions entitled :

MACHINE EQUIPMENT.

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 2.2 /2

>>>

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 3.2 /1

3. UNPACKING − CLEANING

3.1 UNPACKING

Note :

Proceed according to the TRANSPORT INFO sheet 300360 included in

the machine’s documentation.

− Pull out nails from the cover and then from the walls of the case.

− Remove the vacuum-packing plastic.

− Remove the wooden wedges and ropes that hold various items.

3.2 CLEANING THE MACHINE

− Wash carefully with gasoline or petroleum-soaked cloth all rust-protected

surfaces without damaging or disrupting anything.

− Wash on well ventilated premises.

− Avoid using compressed air and substances that could damage plastic

materials.

>>>

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 3.2 /2

>>>

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.1.1 /1

4. LOCATION AND INSTALLATION

4.1 FLOOR PLANS

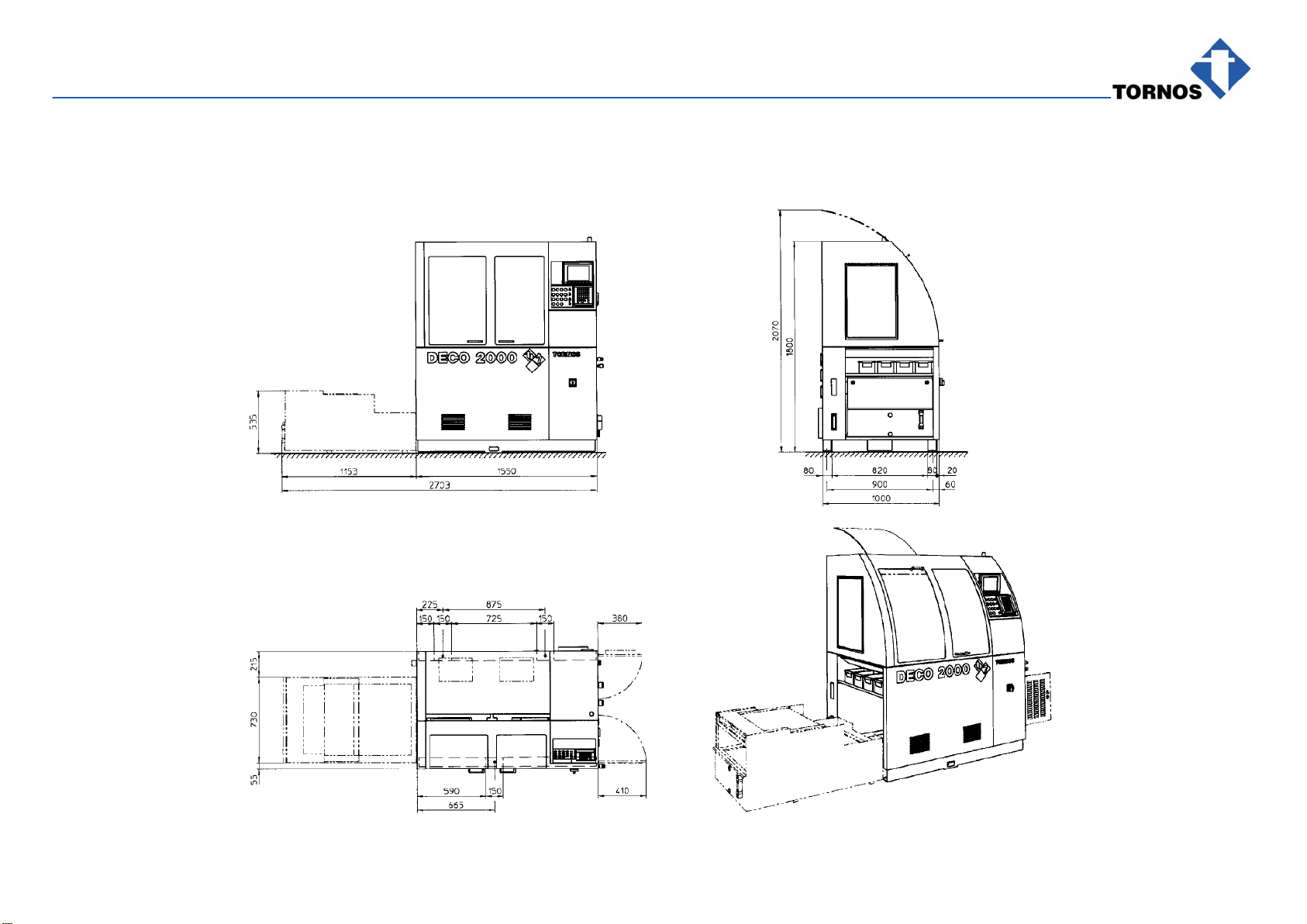

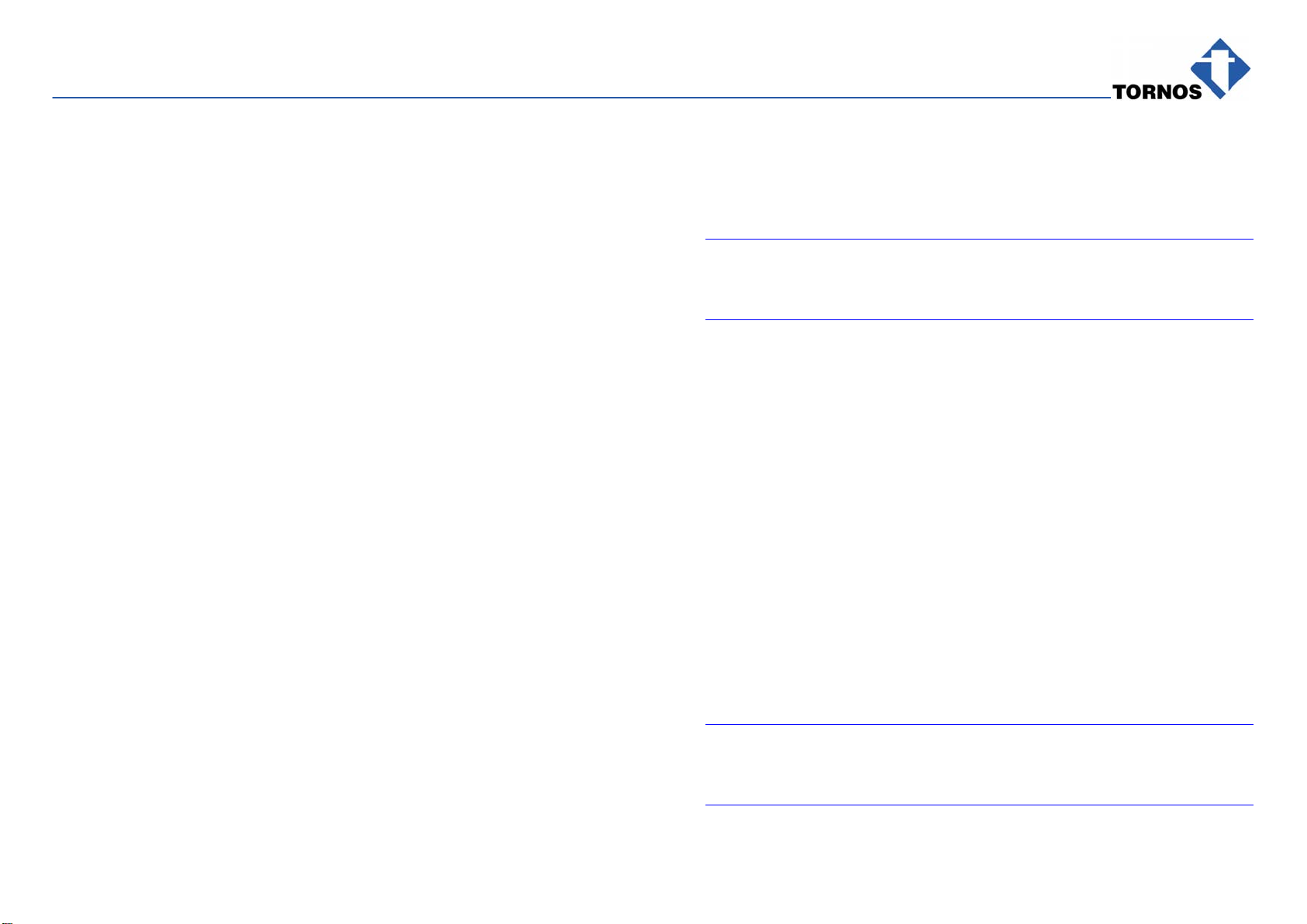

4.1.1 Floor Space of DECO 10e

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.1.2 /2

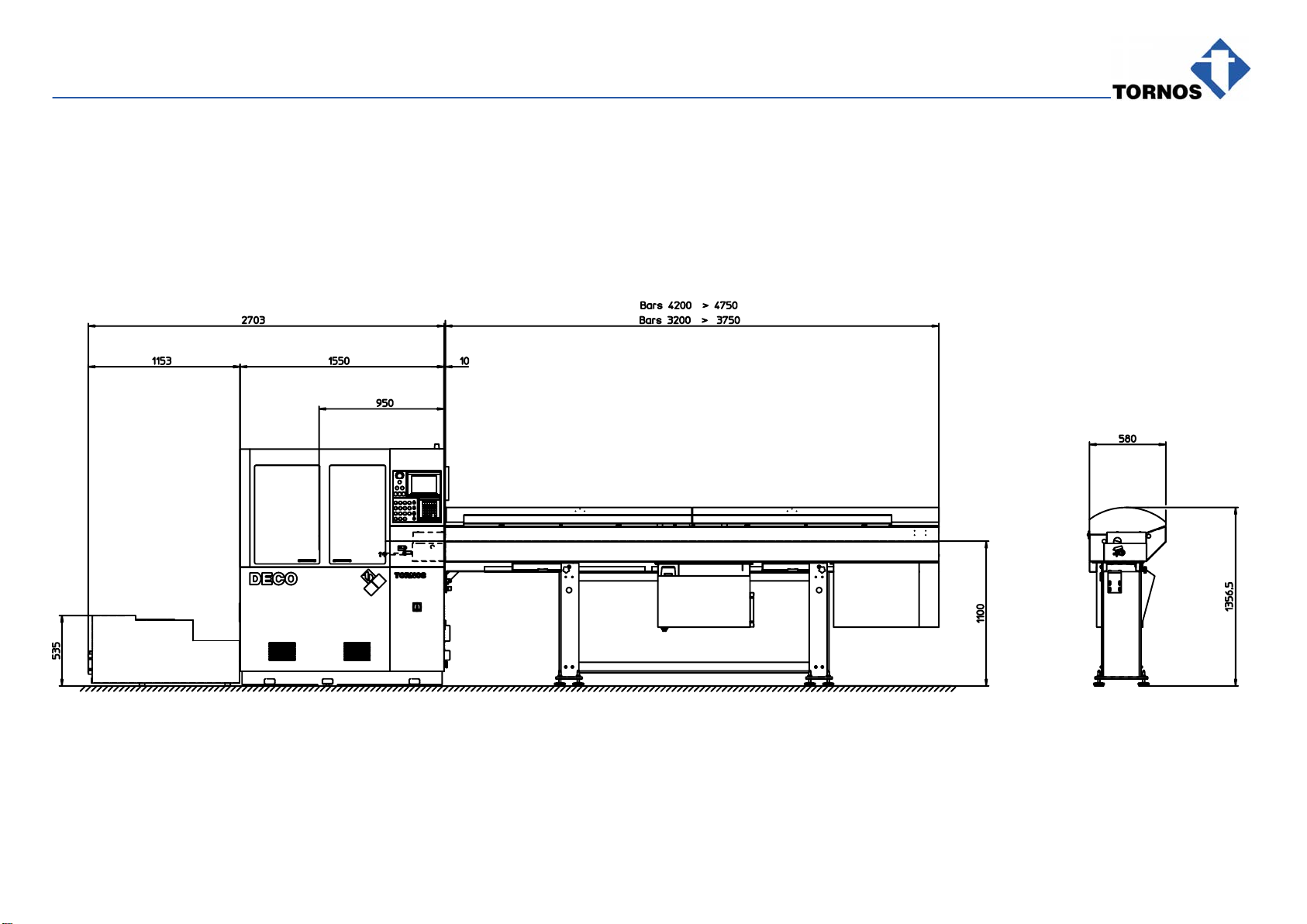

4.1.2 Floor Space with ROBOBAR SSF−107

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.1.3 /3

4.1.3 Floor Space with ROBOBAR SBF−216

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.1.4 /4

4.1.4 Floor Space with Tryton

305166f1

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.3 /5

4.2 FLOOR LOCATION

See Fig. 300.

− Do not level the machine (the floor to be level) :

It rests on three Support Plates D, two in the back and one in the front of

the machine.

− Anchor the machine in the floor with three screws by running them through

the holes in three Support Plates D.

The screws merely fix the machine to the floor and cannot support its

weight.

− Arrange a barfeeder according to its manufacturer’s recommendations.

− Take into account the dimensions of various options that you can attach to

the machine (bar feed tube, barfeeder, conveyor, etc.) because the floor

plan shows the basic machine equipment only.

4.2.1 Floor Preparation

See Fig. 300 and TRANSPORT INFO Sheet 300360.

The machine rests on three support plates.

The floor at these 3 points must be hard, stable, vibration-free and perfectly

level.

4.3 PACKING AND HANDLING FOR REMOVALS

When you move the machine within between your premises, follow the follow-

ing packing and handling requirements :

Note :

See TRANSPORT INFO Sheet 300360 and its Figures 1 to 3 in particu-

lar.

Packing and handling :

IN CASES (seaworthy packing)

− Run cords or chains through as marked.

ON PALLETS (under plastic)

− Pass packing needles of approx. 80 x 80 mm through Rectangular Pass-

ages B.

− Proceed with nailing on the road truck deck.

WITH FORK LIFT TRUCK or LOW LIFT TRUCK

− Pass the fork through Rectangular Passages A.

Fork length min.: 1100 mm

Note :

Before removing the lathe, clean it according to Para: PERIODICAL

CLEANING in your OPERATION & MAINTENANCE instructions.

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.3 /6

D

D

DD

300

FLOOR LOCATION

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.4 /7

4.4 ELECTRIC INSTALLATION

ΔDanger !

For connecting and any other work on the electric equipment, the power must be cut off. The work must be carried out only by an authorized technician to

avoid the danger of electrocution.

Deficient connections may also cause serious damage to the installation.

301Autotransformer

Machine input terminal box to the mains

Autotransformer

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.4.1 /8

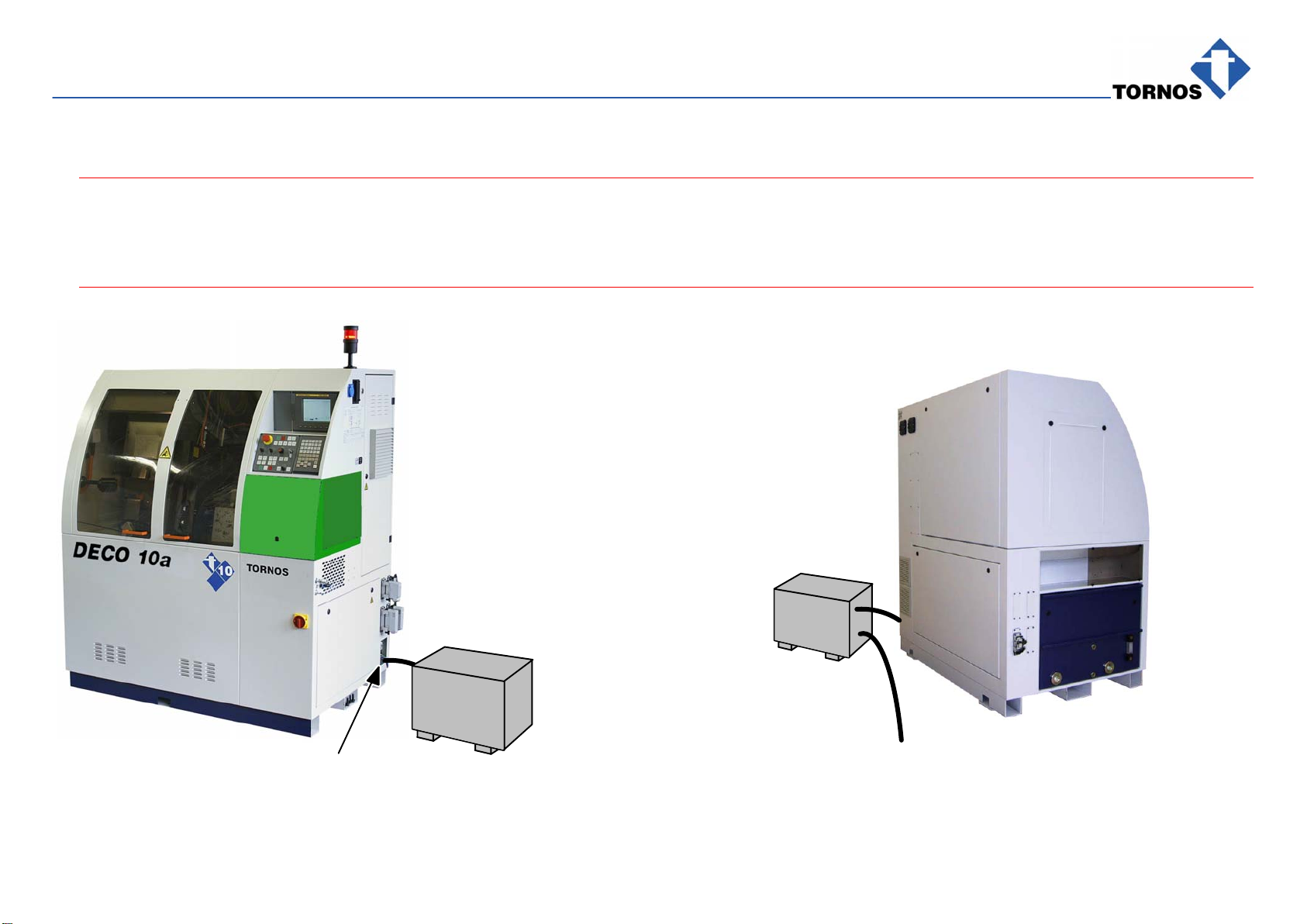

Version 0017

XS94

XS60

(2)

QS0

XS42

XS1

106

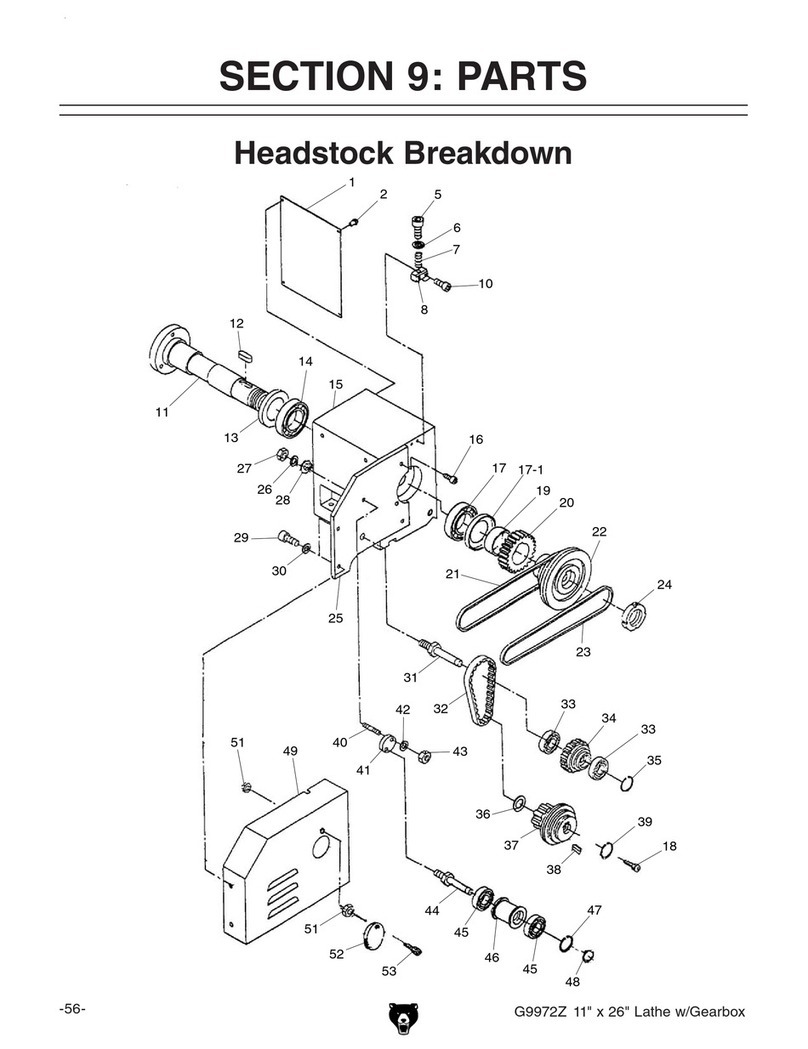

LOCATION OF ELEMENTS

Ref. Description

QS0 Main Switch

XS60 Fire protection system

XS94 Barfeeder socket, fixed

XS94 Barfeeder socket, fixed

XS42 Interface socket for pump, cooling.

(1) Reserve

(2) Socket for eternet

TM1 Autotransformer (if required)

TC1 Mains voltage transformer inside lathe’s enclosure

XS1 Single phase current socket 230V 50Hz

4.4.1 Installation Characteristics

Feature Notes Data

Lathe power: Average effective power:

(acc. to lathe application) 5 kW approx.

Installed power: 8 kVA approx.

Mains tolerances: rated voltage:

frequency: +/−10%

+/−1 Hz for 50/60 Hz

Main circuit-breaker: at machine input 25 A

ΔSee also your instructions: SAFETY REGULATIONS DECO 7a / 10a

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.5 /9

4.5 ELECTRIC CONNECTION DECO 10e

Cut off mains supply

no see chapter

Connecting

TORNOS

autotransformer

Connect mains supply

to machine. Section acc. to ASE 4 mm2or acc.

to local regulations.

Mains Machine

terminal box

see fig. 106

L1

L2

L3

L1

L2

L3

Turn on Main Switch QS0

Check XS1 service socket

voltage.

yes

see fig.106

220V−240V

or US socket voltage

100V−110V ?

Machine properly connected

yes

Mains 400V/50Hz

or 460V/60Hz?

INSTALLATION − DECO 7e / 10e − 0017

300440 en − 01/07 Chap. 4.5.1 /10

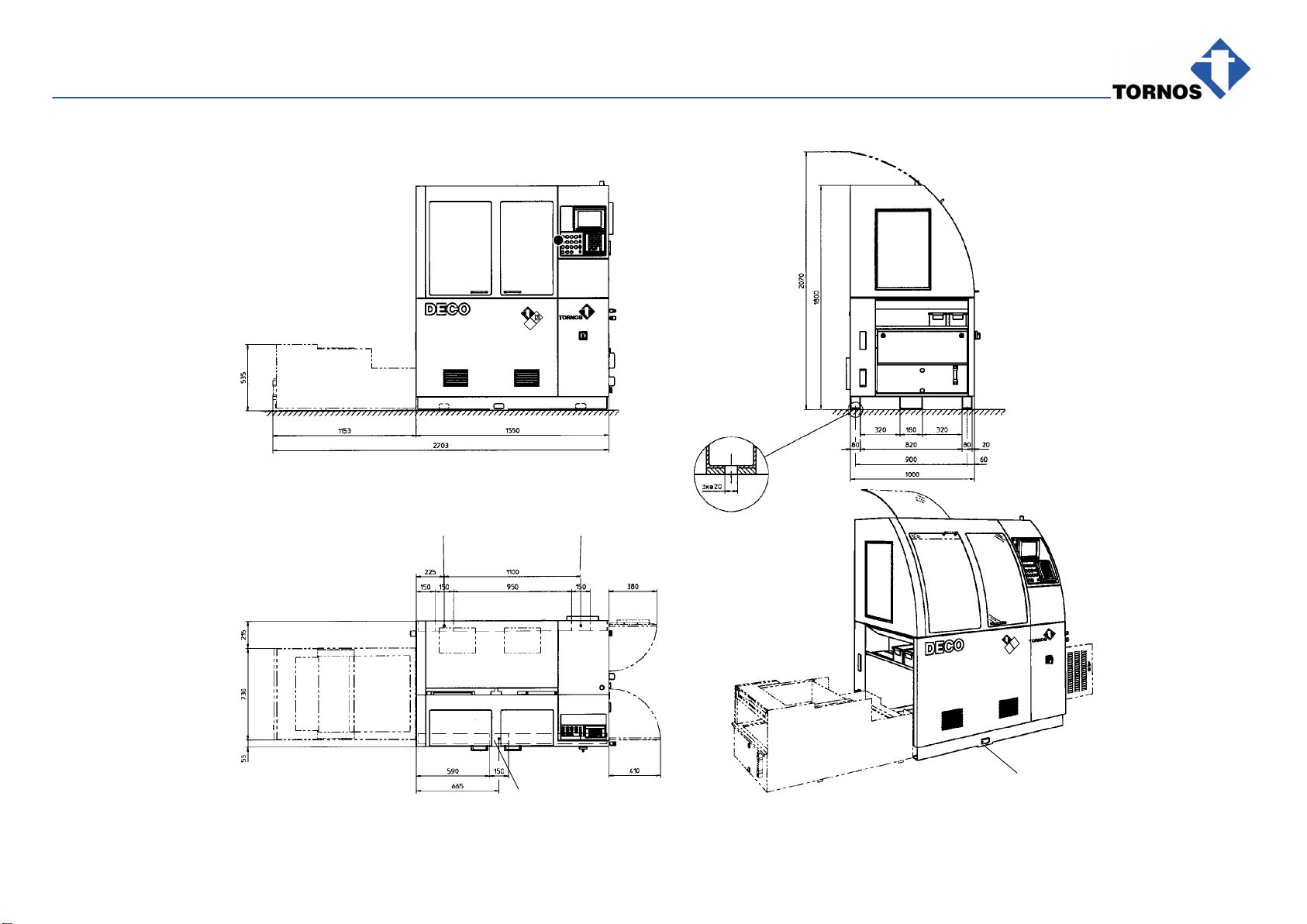

4.5.1 Connecting TORNOS Autotransformer

1

Connect 60 Hz mains supply.

.Caution !

The autotransformer is located

outside the machine.

no

Autotransformer

TORNOS Connecting Non-TORNOS

autotransformer, see para. below

Machine input

terminal box

L1

L2

L3

yes

Cut off mains supply.

50Hz ?

Mains

input

50 Hz

230V

230V

230V 400V

400V

500V 400V

500V

500V

200V

200V

200V Machine input

terminal box

see fig. 106

L1

L2

L3

Mains

input

60 Hz

230V

230V

230V 460V

460V

500V 460V

500V

500V

200V

200V

200V

yes no

2

Connect 50 Hz mains supply.

This manual suits for next models

3

Table of contents

Other tornos Lathe manuals

Popular Lathe manuals by other brands

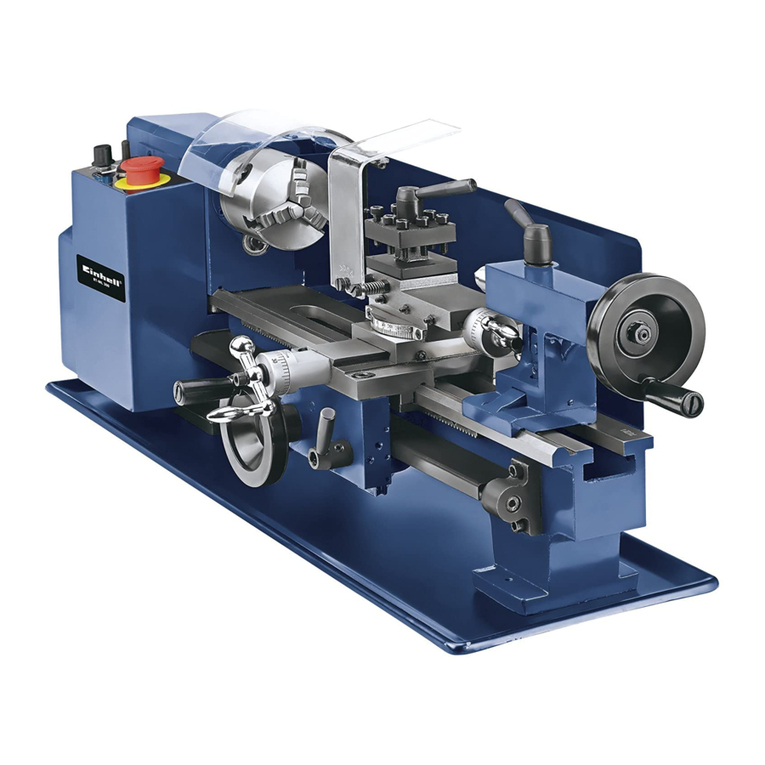

EINHELL

EINHELL BT-ML 300 operating instructions

Wen

Wen LA8800 manual

Scheppach

Scheppach DM1100T Translation of the original instruction manual

Promac

Promac PBD-2870 manual

Central Machinery

Central Machinery 03173 Assembly and operating instructions

Teknatool

Teknatool NOVA Comet II Instructions and parts manual