Laird Cushcraft MA6VA Instruction manual

Other Laird Antenna manuals

Laird

Laird BKIT-VFX69383 Instruction manual

Laird

Laird VLT69273B11J Instruction manual

Laird

Laird Yagi Y1363 User manual

Laird

Laird HDDA5W Series Instruction manual

Laird

Laird VLQ69273B21J Instruction manual

Laird

Laird CMS38606P Programming manual

Laird

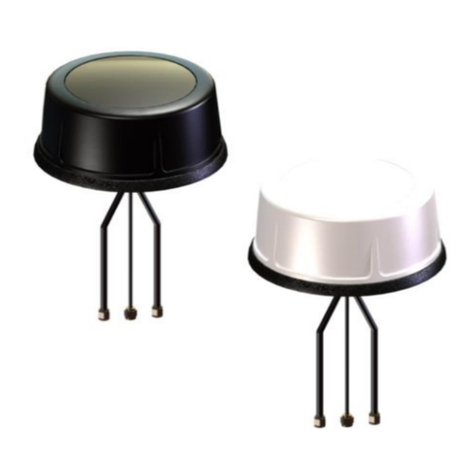

Laird Discadoo User manual

Laird

Laird Phantom Elite Service manual

Laird

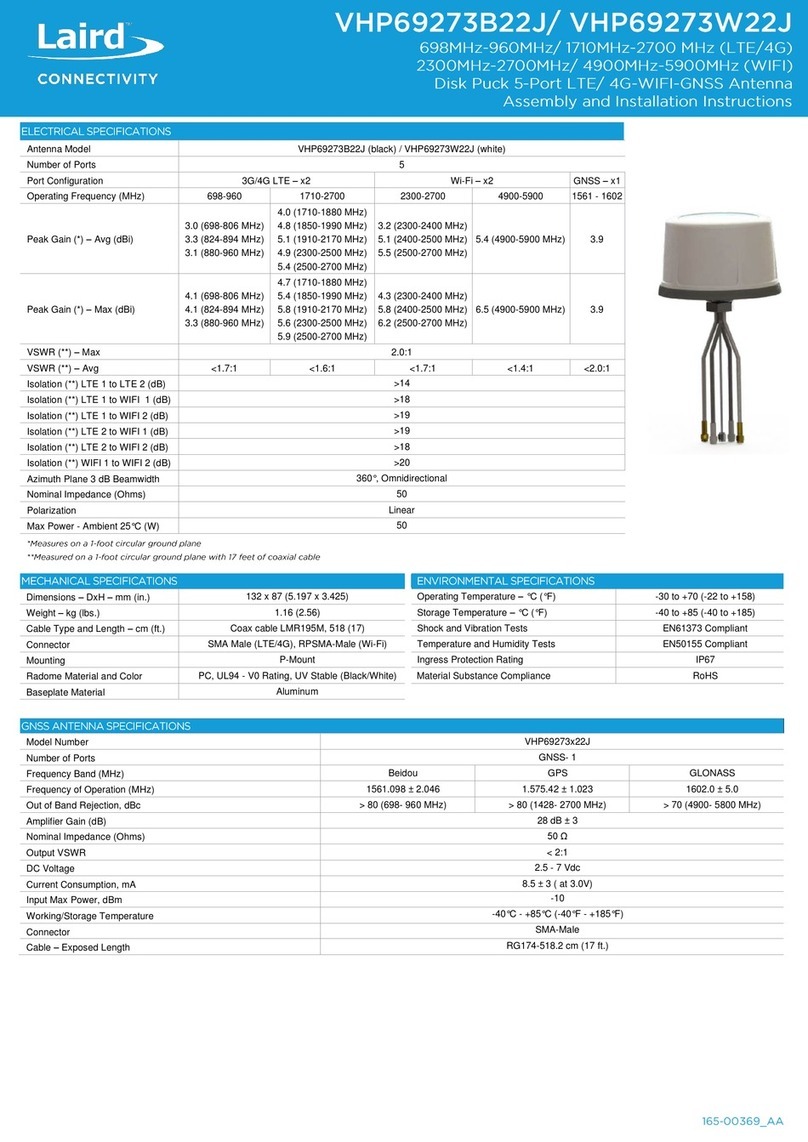

Laird VHP69273B22J Instruction manual

Laird

Laird VG1506 User manual

Popular Antenna manuals by other brands

Alfa Network

Alfa Network APA-L01 Specifications

Naval

Naval PR-422CA Operation manual

Feig Electronic

Feig Electronic ID ISC.ANTH200/200 Series manual

TERK Technologies

TERK Technologies TV44 owner's manual

Directive Systems & Engineering

Directive Systems & Engineering DSE2324LYRMK quick start guide

HP

HP J8999A instructions

CommScope

CommScope CMAX-OMFX-43M-I53 Installation instruction

Ramsey Electronics

Ramsey Electronics DAP25 Kit assembly and instruction manual

COBHAM

COBHAM SAILOR 800 VSAT Replacement procedure

Trango Systems

Trango Systems AD900-9 Specification sheet

Steren

Steren ANT-100 user manual

IWCS

IWCS iriBelt II Quick start user guide