5

Laird Thermal Systems s.r.o.

Operation Manual

Version: 1.1

1505.00

1. Description

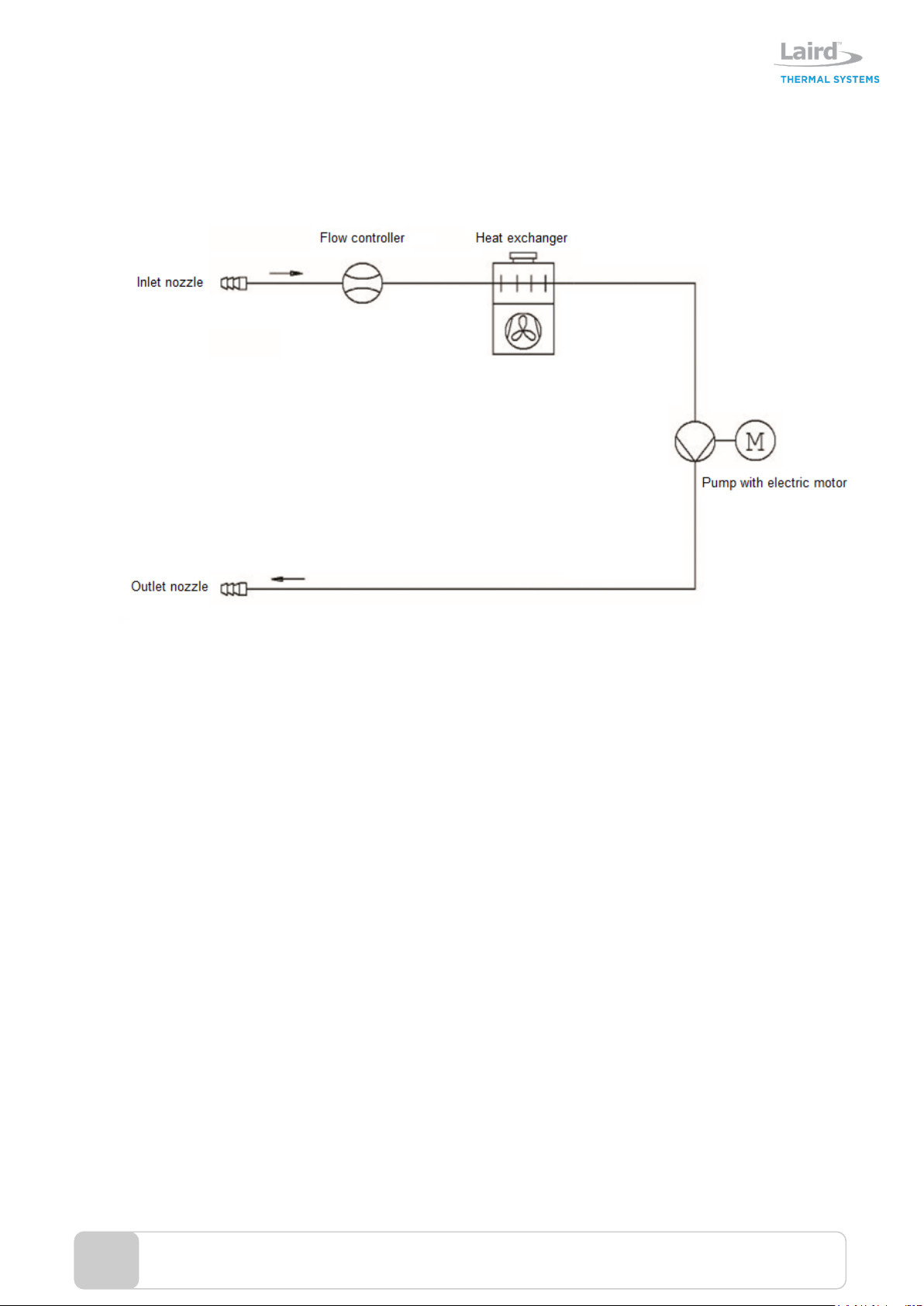

The WL 500 cooling unit is intended to remove heat from a liquid circuit. The coolant can be either

water or a mixture of water and water-glycol (antifreeze). Water circulates in a closed loop between

the ambient cooling system and a cold plate at the heat source. Heat is removed from water by an air-

cooled heat exchanger. The capacity of the cooling unit is dependent on the temperature differential,

which is defined as the difference between the ambient temperature and the water outlet temperature.

The cooling unit is designed to remove 500 W of heat at a temperature differential of 13°C. The water

inlet and water outlet are marked as Water in and Water out.

The maximum forward pressure is limited by a bypass valve, which has been integrated into the

pump. The coolant flow is controlled by a flow switch that opens when flow falls below a set rate.

Cooling hoses supplied by user are connected to threaded nozzle that can accommodate an 8 mm

hose ID.

The water flow is monitored by an adjustable flow switch. The signal of the flow switch is available at

a potential free safety circuit. The permissible contact rating for the safety circuit is 125 VAC/1A/50

VA.

A bypass valve limits the water pressure.

Note: Flow switch and bypass valve are adjusted at factory and set according to specification.

2. Safety Precautions

Note: Read manual before operating the cooling unit.

2.1 Electrical Danger

Work on electrical installations must be carried out only by trained and authorized electricians

Input power must be rated 230 VAC at 50/60 Hz.

Before starting any service work on the cooling unit, please disconnect from the main power

source.

2.2 Safe Operation

Use Water or Water/Glycol as coolant.

Run the cooling unit at the correct coolant level, otherwise the pump might degrade, and cooling

capacity will be reduced.

Use cooling hoses that can handle max pressure of the liquid circuit and is resistant to corrosion

from coolant.

Never operate the unit if it is damaged or leaking.

2.3 Environmental Issues

Environmentally hazardous substances must be used or disposed of according to regional

regulations.

When dealing with working fluids, always be aware of the safety data sheet of the corresponding

manufacturer and use appropriate personal protective gear.