Sivu 3 / 20

Table of contents

General.................................................................................................................................................2

Read before use ...................................................................................................................................2

1. DECLARATION OF CONFORMITY ..................................................................................................4

2. PURPOSE OF USE ..........................................................................................................................5

3. SAFETY PRECAUTIONS ..................................................................................................................5

4. IDENTIFICATION INFORMATION AND SPAREPARTS.....................................................................6

4.1. Identification plate ............................................................................................................................ 6

4.2. Maintenance services........................................................................................................................ 6

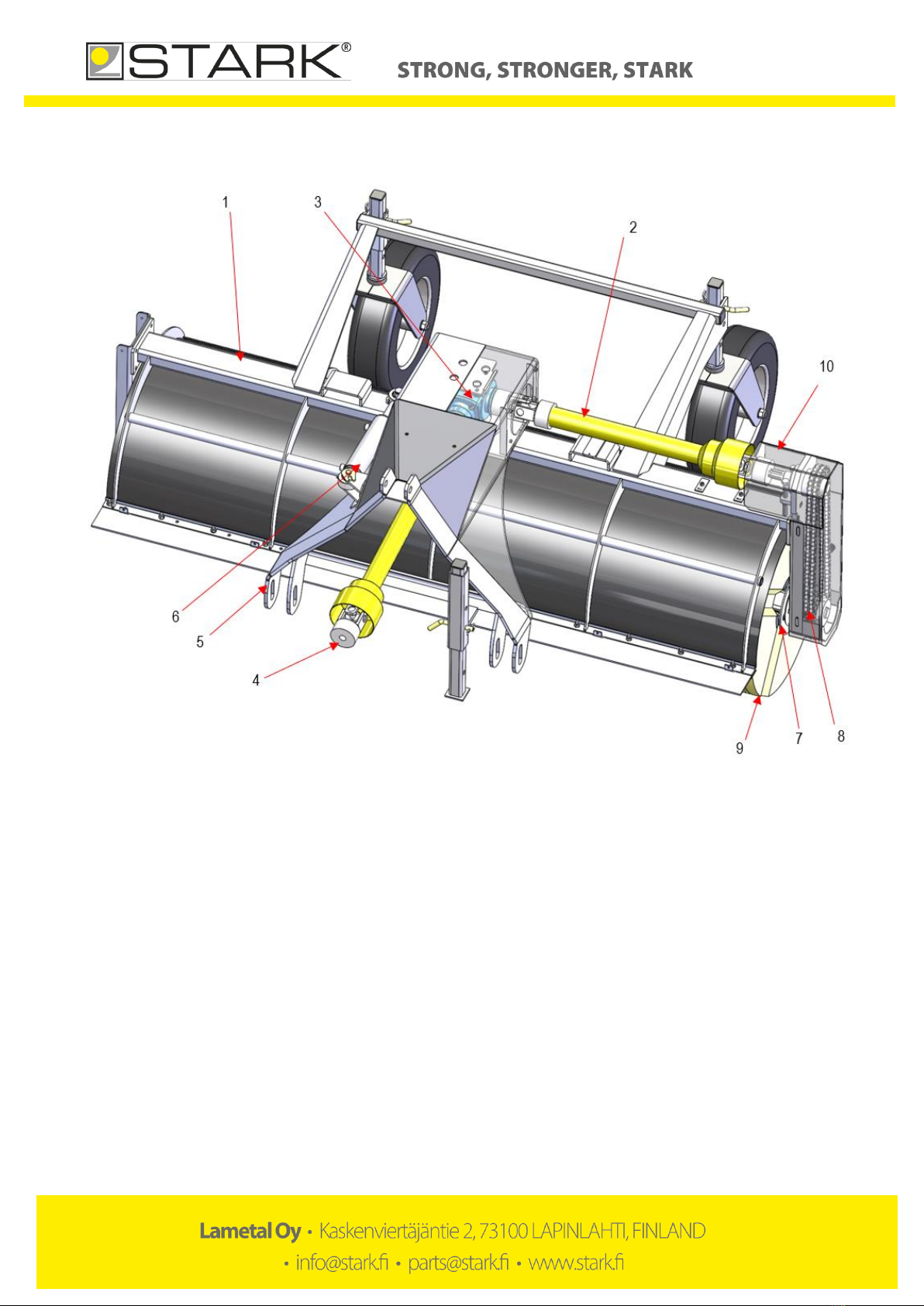

5. MAIN PARTS OF THE BACK BROOM .............................................................................................7

6. USING THE BACK BROOM.............................................................................................................8

6.1. Attaching the broom to the base machine........................................................................................ 8

7. OPERATING THE BACK BROOM ....................................................................................................9

7.1. Using the back broom........................................................................................................................ 9

7.2. Overload switch............................................................................................................................... 10

7.3. Changing the brush rings................................................................................................................. 11

7.4. Adjusting the chains ........................................................................................................................ 12

7.5. Removing the back broom from the base machine........................................................................ 13

7.6. Transferring the back broom........................................................................................................... 13

8. MAINTENANCE OF THE BACK BROOM .......................................................................................14

8.1. General safety precautions for the use and maintenance.............................................................. 14

8.2. Tightening torque............................................................................................................................ 14

8.3. Daily maintenance........................................................................................................................... 14

8.4. Maintenance after first 10 hours of operation ............................................................................... 14

8.5. Maintenance at 50-working hour intervals or on a weekly basis ................................................... 14

8.6. Lubrication points............................................................................................................................ 15

8.7. Adding oil to the angle gearbox....................................................................................................... 16

8.8. Propeller shafts................................................................................................................................ 17

9. HYDRAULICS................................................................................................................................18

10. WARRANTY POLICY .................................................................................................................20