9

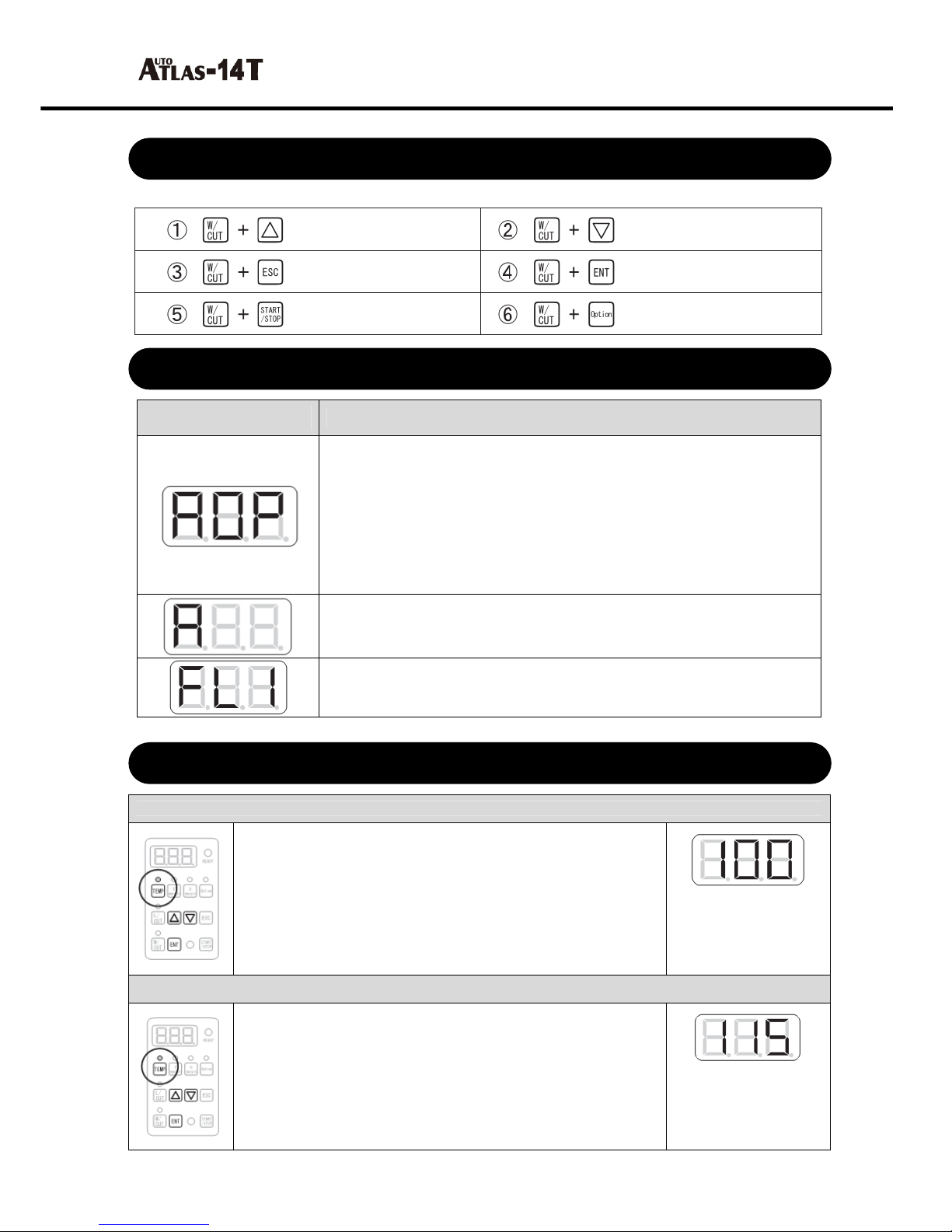

Basic operation of this product is done by combining [W/CUT] ith other buttons.

LCD display Reason for stopping and solution

Jam sensor detection AOP]

The processed material does not come out of the back and is caught

inside the product.

Open the top unit of this product and slo ly close hile taking the

material out.

※ Press [ESC] to cancel panel display.

The top unit is open. AOP]

The top unit of this product is not closed properly.

Since processing cannot be done as is, open the unit and close it again.

Make sure that it is not opened by pulling the handle before continuing

ith the processing.

※ Press [ESC] to cancel panel display.

Processing is finished for the number of paper set. A ]

If the number of processed paper is set, the product ill stop once

processing is done according to the number setting.

※ Press [ESC] to cancel panel display.

Film end detection F L 1 ]

Since top laminate film or bottom laminate film is used up, turn the

po er off and set ne films.

※ Press [ESC] to cancel panel display.

※ Contact our company or the seller hen other error occur.

To adjust temperature of heat roller

Initial setting: 100˚C

Adjustable range: 10-120˚C

1. Turn on the TEMP LED and press [ENT] button.

2. Value on the display ill flicker. (Sho ing that you entered

setting mode)

3. Press △ and ▽ buttons to set the number ithin

10~120˚C.

4. When [ENT] button is pressed again, flickering display is

changed to on and setting is ended.

※ Press [ESC] button to stop during setting.

※ Setting is remembered hen po er is turned off.

Po er is connected

and surface

temperature of heat

roller is displayed

[100]=100˚C

To adjust temperature of metal roller

Initial setting: 115˚C

Adjustable range: 10-120˚C

1. Press [ENT] button hile TEMP LED is flashing

2. Value on the display ill flicker. (Sho ing that you entered

setting mode)

3. Press △ and ▽ buttons to set the number ithin

10~120˚C.

4. When [ENT] button is pressed again, flickering display is

changed to on and setting is ended.

※ Press [ESC] button to stop during setting.

※ Setting is remembered hen po er is turned off.

Po er is connected

and surface

temperature of metal

roller is displayed

[115]=115˚C