Contents

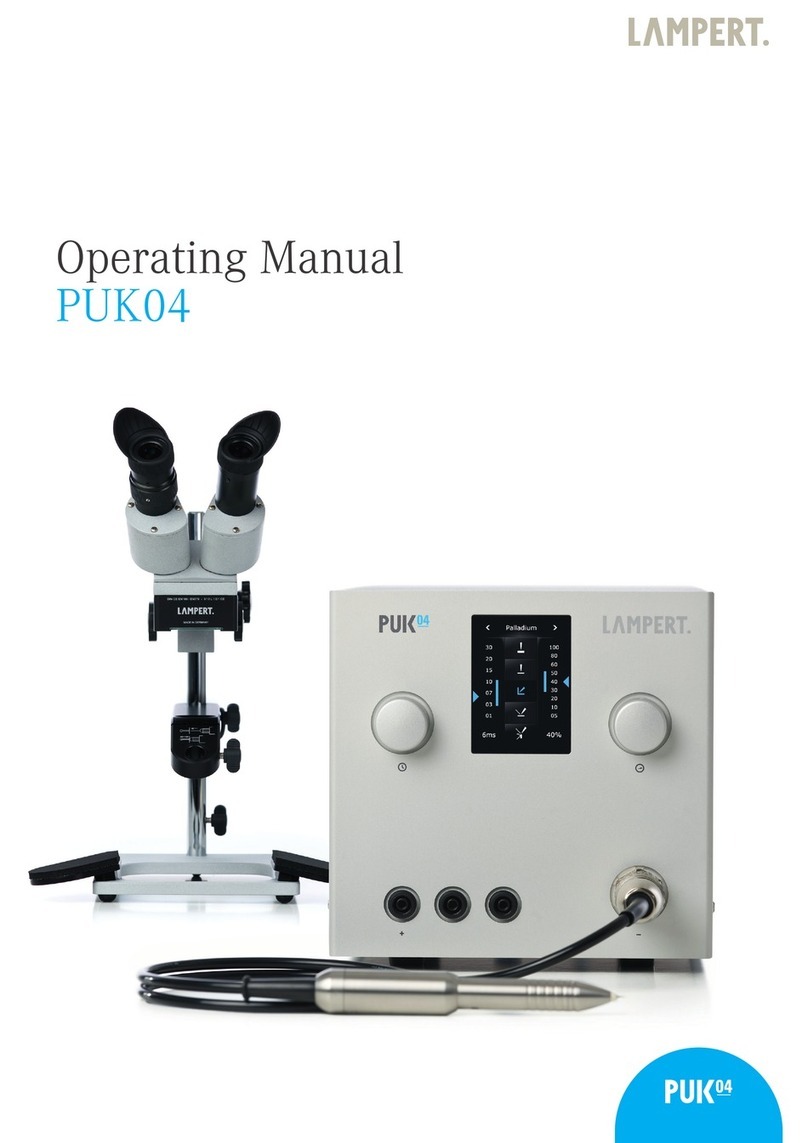

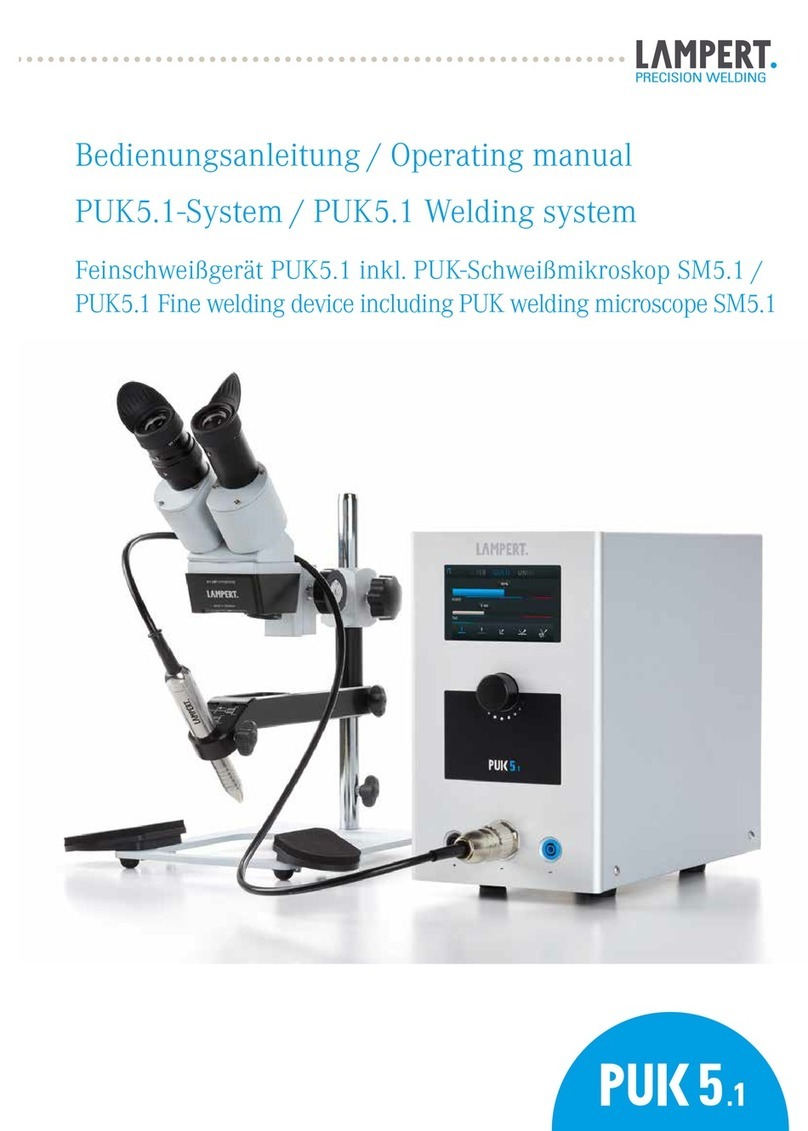

Issue EN 2022/05 PUK 6 Operating manual

Contents

1About this operating manual ............................................................................6

1.1 General....................................................................................................................6

1.2 Presentation of information....................................................................................7

Handling instructions ...................................................................................................................7

Application tip ..............................................................................................................................7

1.3 Structure of the warnings.......................................................................................8

2General safety regulations............................................................................. 10

2.1 Principles.............................................................................................................. 10

2.2 Intended use ........................................................................................................ 10

2.3 Foreseeable misuse............................................................................................. 11

2.4 Safety instructions............................................................................................... 11

General information ...................................................................................................................11

Personal protective equipment..................................................................................................11

Handling protective gas cylinders .............................................................................................12

During transport .........................................................................................................................12

During installation......................................................................................................................12

During commissioning................................................................................................................12

During operation.........................................................................................................................13

Maintenance and inspection work............................................................................................13

During disassembly ....................................................................................................................14

2.5 Residual risks for device operation ..................................................................... 14

2.6 Selection and qualification of personnel ............................................................ 14

2.7 Safety devices...................................................................................................... 15

2.8 Safety signs ......................................................................................................... 16

3Structure and function .................................................................................... 18

3.1 Functional description ......................................................................................... 18

Scope of delivery........................................................................................................................18

3.2 General overview................................................................................................. 19