VersaPour Manual

www.lancerbeverage.com Page 2 of 13

Hoshizaki Lancer reserve the right to change specifications without notice.

Images are for illustration purposes only as product may vary. No 066 30 October 2017

Table of contents

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product and should be handed over to the operator after

the installation and preserved for any further consultation that may be necessary. Please read carefully the

guidelines and warnings contained herein as they are intended to provide the user with essential information

for the continued safe use and maintenance of the product. In addition, it provides GUIDANCE ONLY to the

user on the correct services and site location of the unit.

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly inspected before shipment. At the time of

shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the carton

for visible damage. If damage exists, have the carrier note the damage on the freight bill and file a claim with

carrier. Responsibility for damage to the dispenser lies with the carrier.

The installation and relocation, if necessary, of this product must be carried out by qualified

personnel with up-to-date safety and hygiene knowledge and practical experience, in accordance

with current regulations.

1. Specifications and Features ............................................................................................ 3

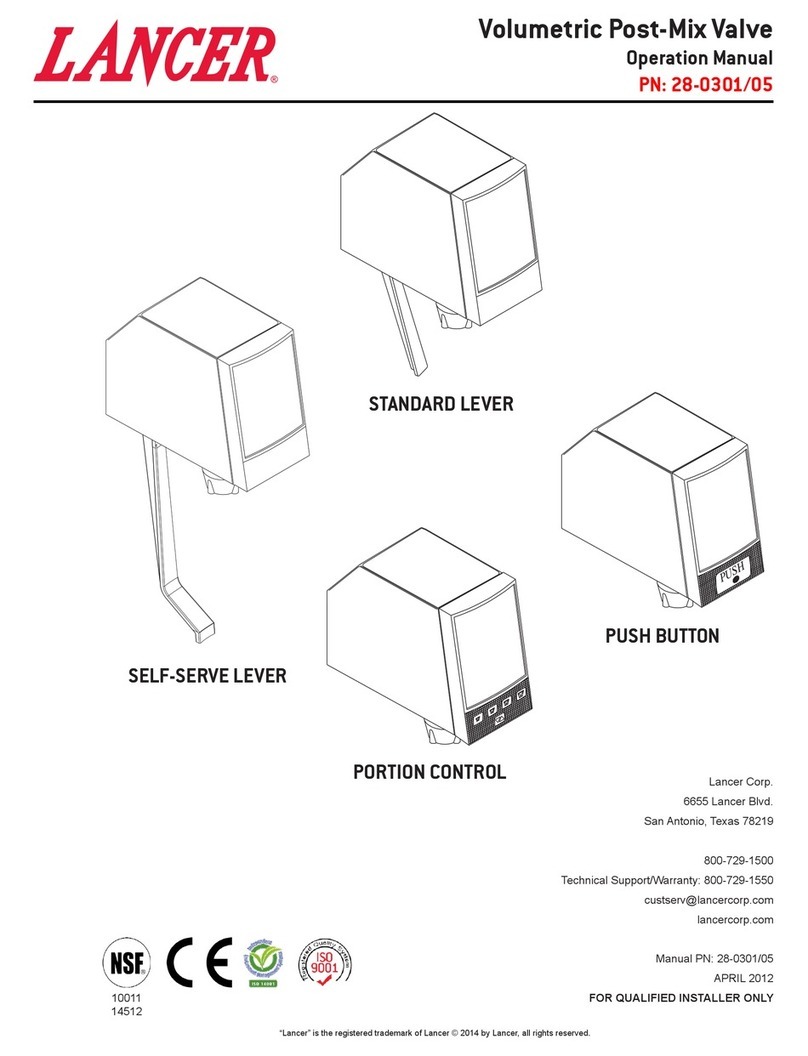

1.1. Models..........................................................................................................................................3

1.2. Product Features..........................................................................................................................3

1.3. Specifications ...............................................................................................................................3

2. Safety Information............................................................................................................ 4

2.1. Safety Instructions........................................................................................................................4

3. Installation ........................................................................................................................ 4

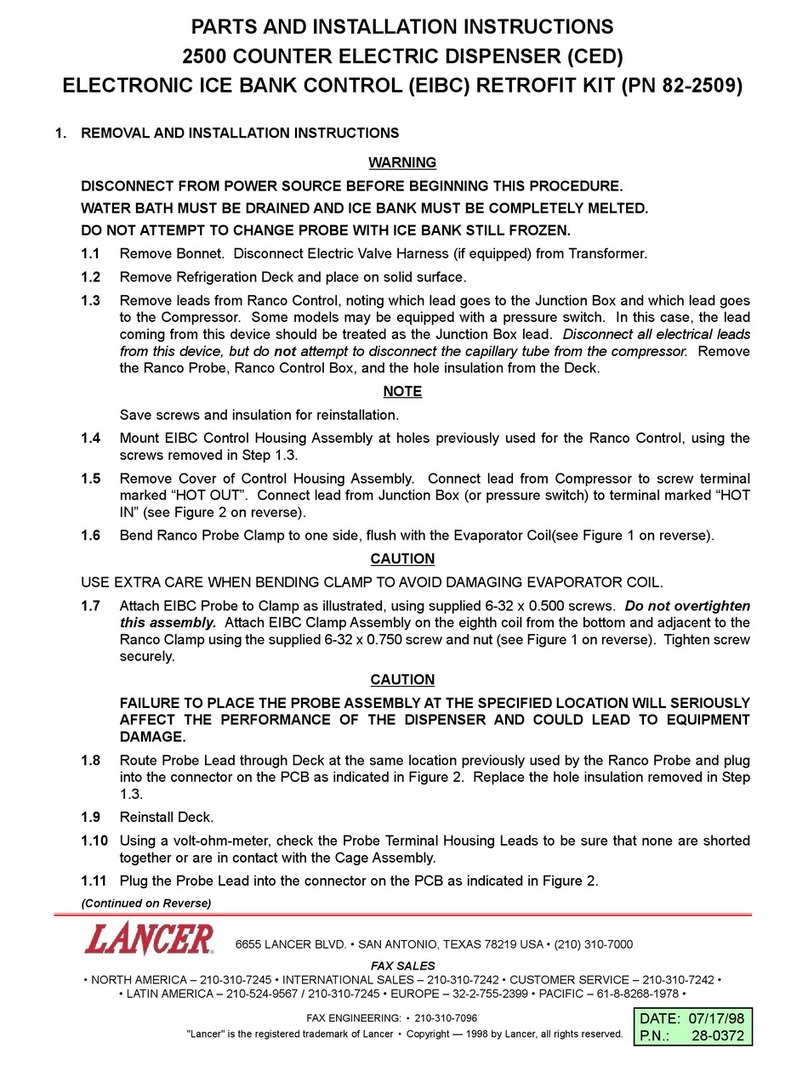

3.1. Removal of Existing Valve ...........................................................................................................4

3.2. Installation of Valve......................................................................................................................4

3.3. Adjust Water Flow........................................................................................................................5

3.4. Adjust Water to Syrup Ratio.........................................................................................................6

3.5. Portion Control Programming.......................................................................................................6

4. Cleaning and Sanitizing ................................................................................................... 7

4.1. Daily Cleaning ..............................................................................................................................7

4.2. Bi-Weekly Sanitising.....................................................................................................................7

5. Assembly Diagrams & Parts List..................................................................................... 8

5.1. VersaPour Assembly (Model 100 SSL, PB, PC 3.0 oz/sec)........................................................8

5.2. VersaPour Assembly Parts List....................................................................................................9

5.3. Mounting Block...........................................................................................................................10

5.4. Tools...........................................................................................................................................10

5.5. Additional Valve Kits...................................................................................................................11

5.6. Label Size...................................................................................................................................11

6. Trouble Shooting............................................................................................................ 11

7. Certificate of Warranty ................................................................................................... 13