IS-MDC-12 Instruction Manual

CEB00249-53-000 Page 7 of 12 Issue 3 19 January 2021

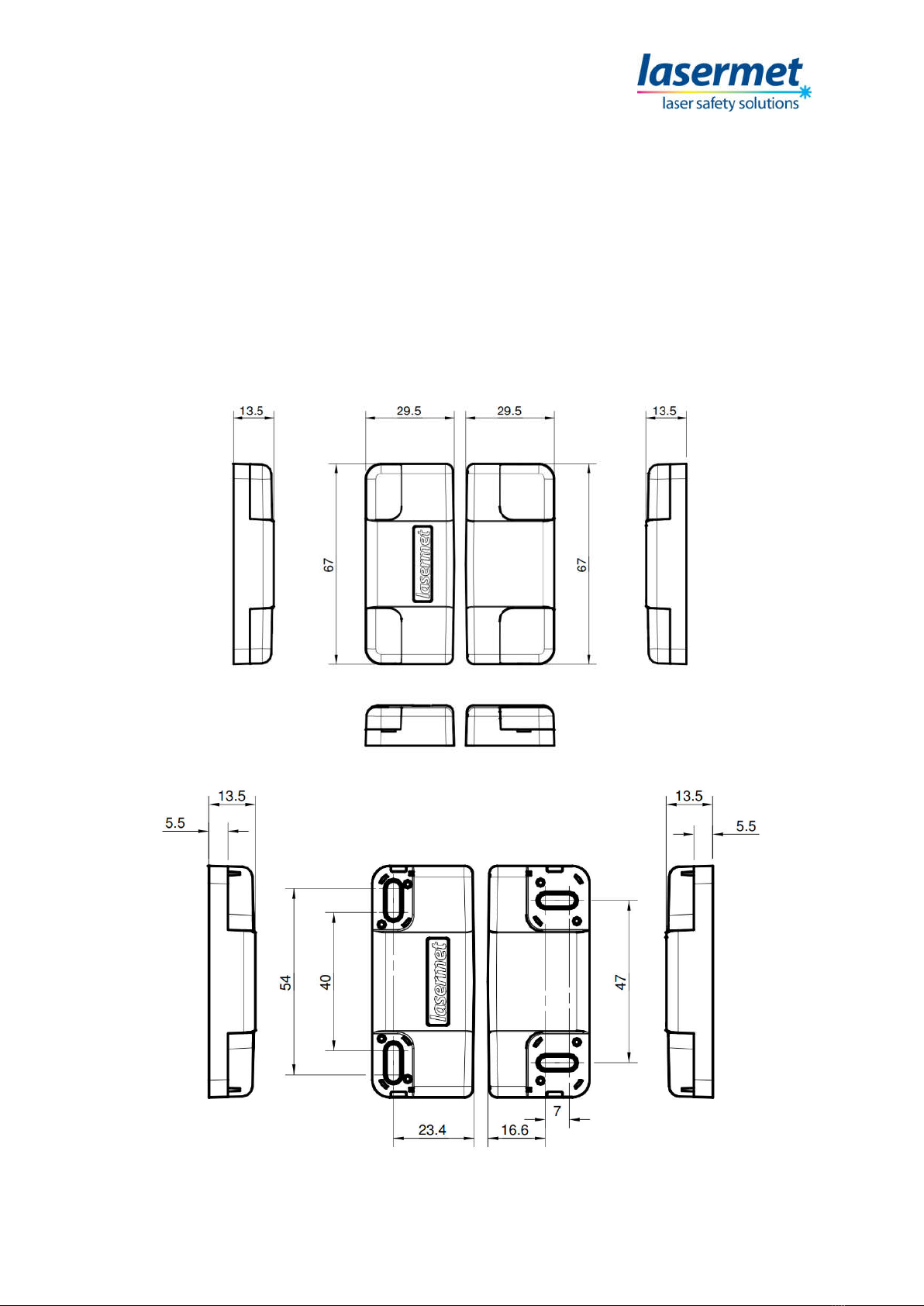

The part with the Lasermet badge and the cable

attached (known as the switch) is normally affixed to

the door frame, and the other part (known as the

actuator) is attached to the door. The fixing hole

positions are shown above and the usual mounting

arrangement on a door on the left.

It is usual to site the units close to the opening side of

the door so that even a slight opening is detected. It

is also usually preferable to position the units in the

most inaccessible position to discourage tampering.

By default, the lead of the switch unit exits at the

back. It is visually preferable if a hole can be drilled

into the architrave such that the lead can be hidden

out of sight. The lead may then be buried in the wall

or taken into mini trunking adjacent to the architrave.

If this is not possible the side of the switch body

adjacent to the lead may be carefully broken out to

allow the lead to run along the surface. Take care not

to damage the lead when making the breakout.

On some doors the door surround (architrave)

projects forward of the door face. The IS-MDC-12 will

work with the switch unit up to 8mm or more in front

of the actuator unit, as shown in the figure. This may

reduce or eliminate the need for cutting into the

architrave.

Some experimentation using temporary means of

attachment may be useful to determine the optimum

position, see the section, ‘Testing with a Multimeter’.

Fit the two parts to the door using the screws

provided, but do not tighten the screws fully or fit the

screw caps until the system has been completely

tested. The two long flat sides of the units should

face and be aligned with each other. The gap

between the units should be in the range 1mm –

5mm.

The screw holes in the two parts are slotted to allow

for adjustment and alignment. If the lead has been fed into a hole behind the switch part, the hole

may need to be adjusted to allow for any repositioning of the switch. It is suggested that the screw

covers are not fitted until the switch has been tested, as they may get accidentally broken if

subsequently removed.